(9) TAPPET ADJUSTMENT

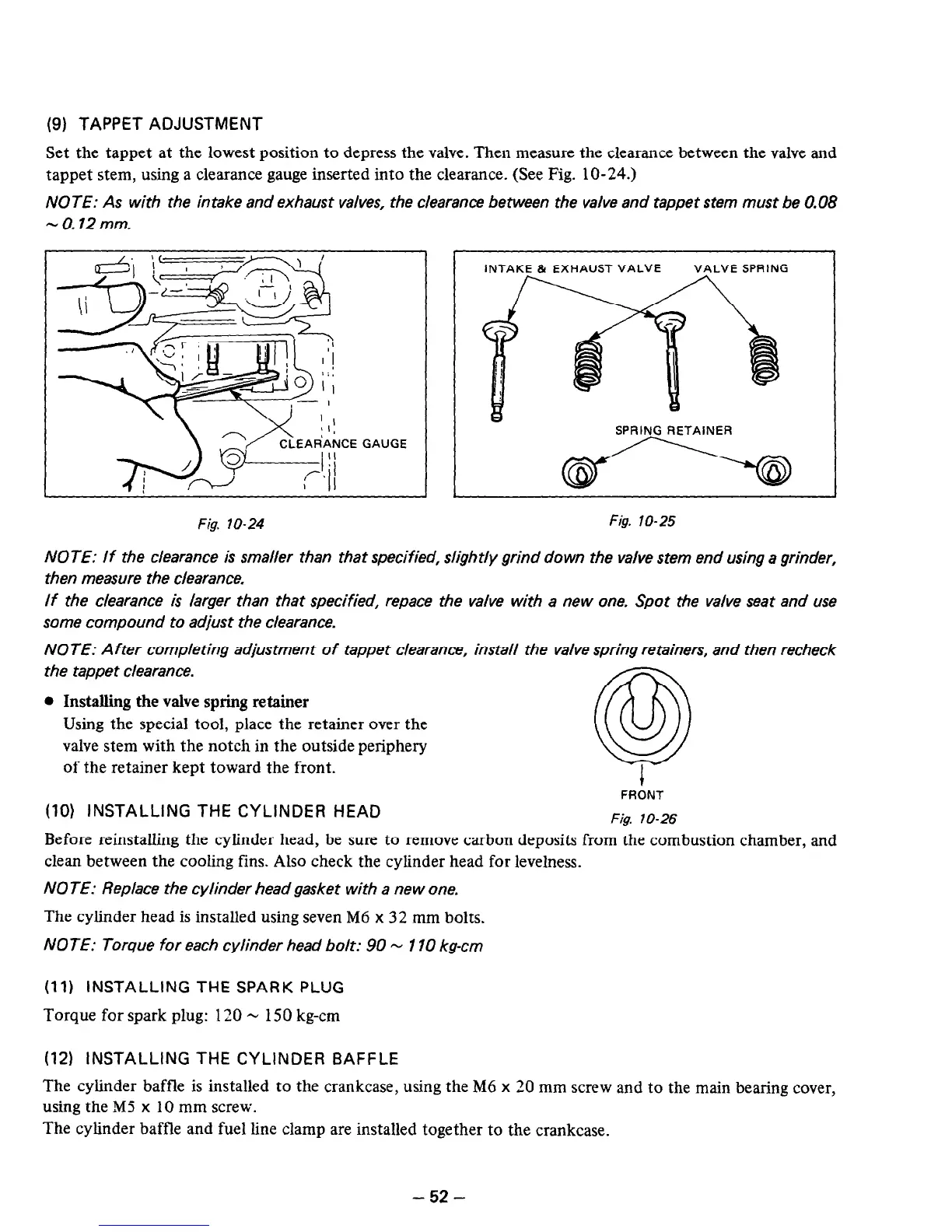

Set the tappet at the lowest position to depress the valve. Then measure the clearance between the valve and

tappet stem, using a clearance gauge inserted into the clearance. (See Fig. 10-24.)

NOTE: As with the in take and exhaust valves, the clearance between the valve and tappet stem must be 0.08

- 0.12 mm.

GAUGE

Fig. 10-24

Fig. lo-25

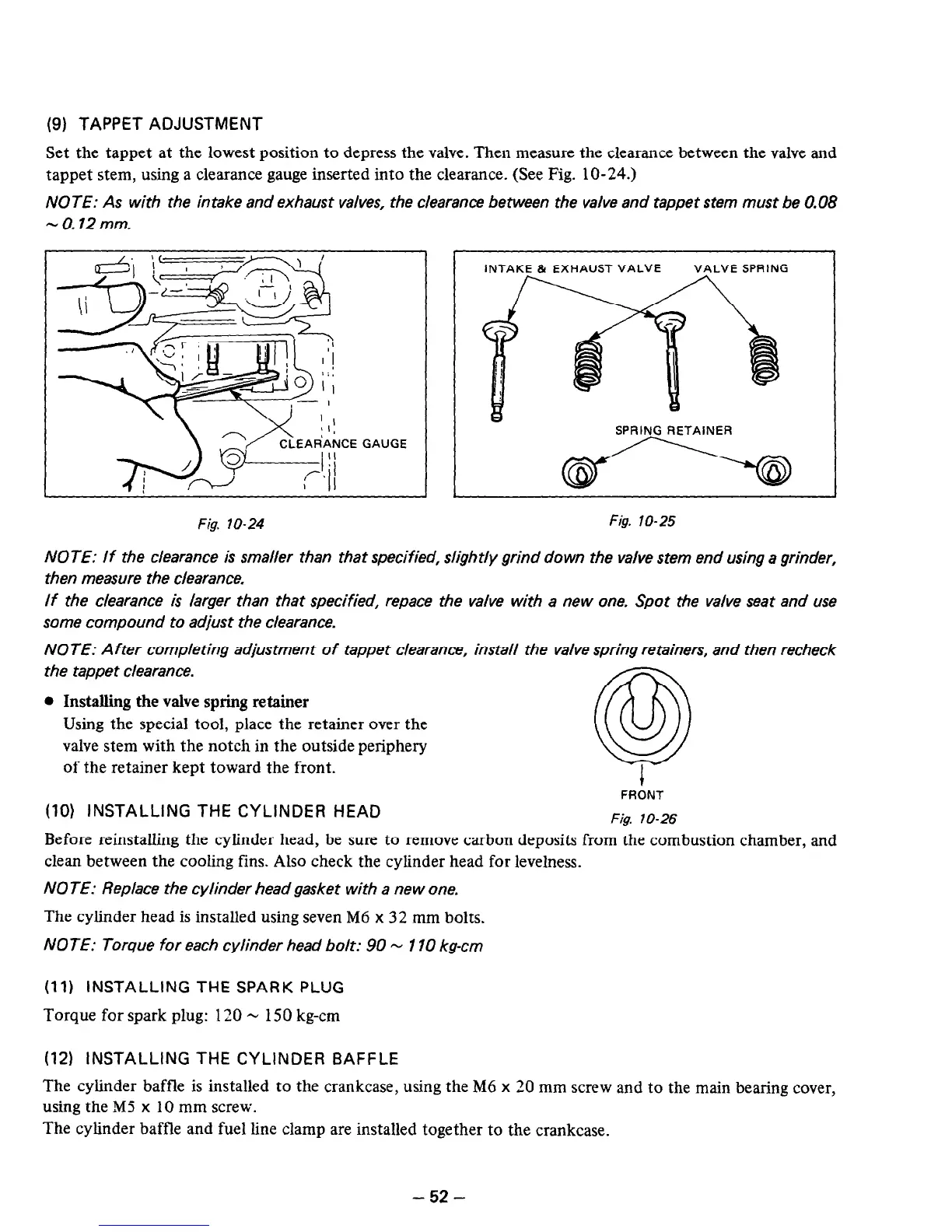

INTAKE & EXHAUST VALVE VALVE SPRING

SPRING RETAINER

NOTE: If the clearance is smaller than that specified, slightly grind down the valve stem end using a grinder,

then measure the clearance.

If the clearance is larger than that specified, repace the valve with a new one. Spot the valve seat and use

some compound to adjust the clearance.

NOTE: After completing adjustment of tappet clearance, install the valve spring retainers, and then recheck

the tappet clearance.

l

Installing the valve spring retainer

Using the special tool, place the retainer over the

valve stem with the notch in the outside periphery

of the retainer kept toward the front.

@

I

FRONT

(10) INSTALLING THE CYLINDER HEAD

Fig. 70-26

Before reinstalling the cylinder head, be sure to remove carbon deposits from the combustion chamber, and

clean between the cooling fins. Also check the cylinder head for levelness.

NOTE: Replace the cylinder head gasket with a new one.

The cylinder head is installed using seven M6 x 32 mm bolts.

NOTE: Torque for each cylinder head bolt: 90 - 1 IO kg-cm

(11) INSTALLING THE SPARK PLUG

Torque for spark plug: 120 - 150 kg-cm

(12) INSTALLING THE CYLINDER BAFFLE

The cylinder baffle is installed to the crankcase, using the M6 x 20 mm screw and to the main bearing cover,

using the M5 x 10 mm screw.

The cylinder baffle and fuel line clamp are installed together to the crankcase.

- 52 -

Loading...

Loading...