1-4 Contactor Product Description

1502-UM051E-EN-P – June 2013

Contactor Operation (cont.) IntelliVAC Control (Series E)

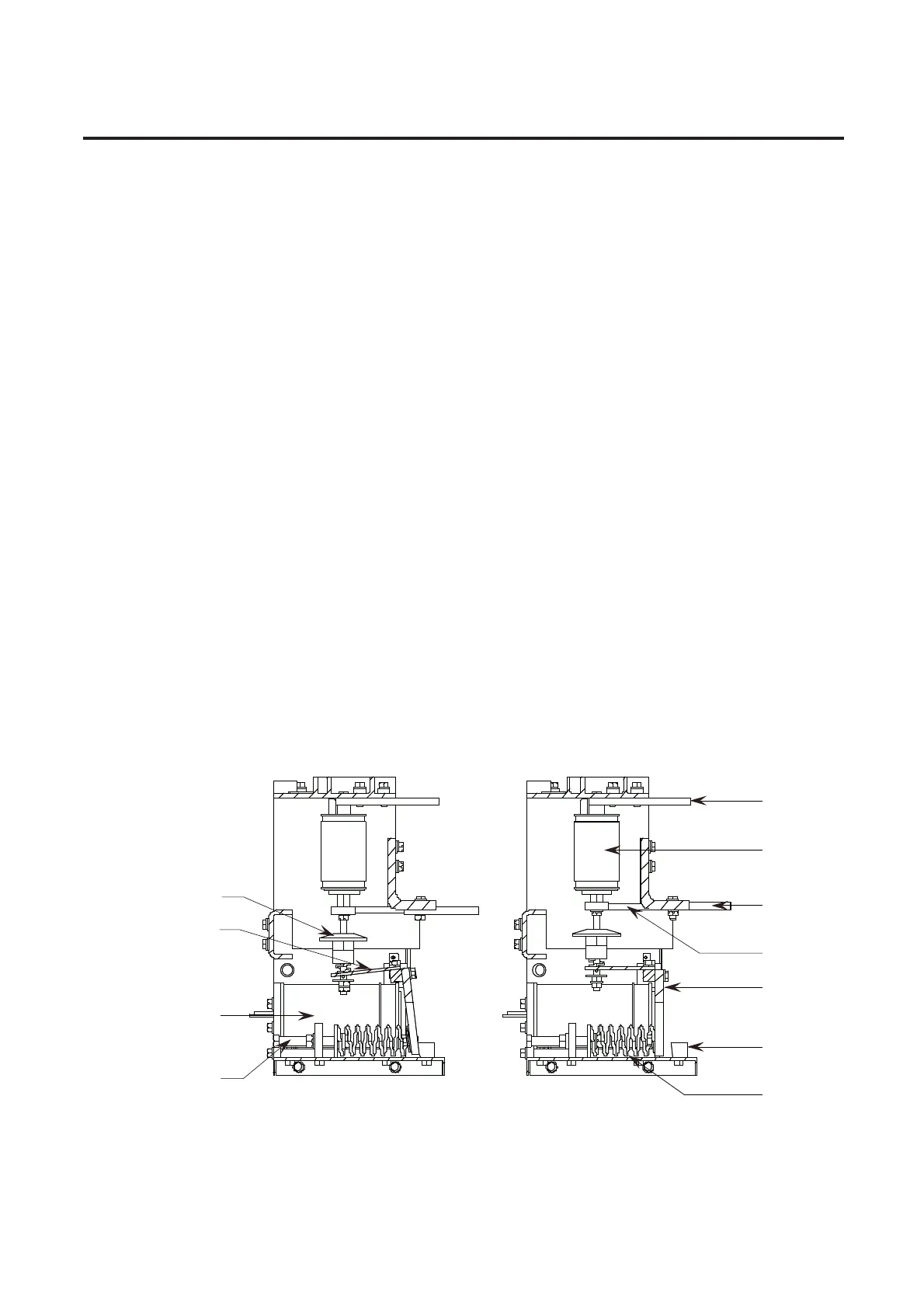

e electrically held vacuum contactor operates as follows:

r 8IFOUIF*OUFMMJ7"$BOE*OUFMMJ7"$1MVTDPOUSPMNPEVMFTSFDFJWFBDMPTF

command, the contactor coil is energized, the current creates an electromagnet

in the coil.

r ăFFMFDUSPNBHOFUQVMMTUIFBSNBUVSFQMBUFUPXBSETUIFDPJMDPSFSPUBUJOHUIF

sha and causing the actuator plate to move upwards.

r "TUIFBDUVBUPSQMBUFNPWFTJUQVTIFTUIFJOTVMBUPSBOENPWBCMFTIBĕVQDMPT-

ing the contacts in the vacuum bottle.

r ăF*OUFMMJ7"$BOE*OUFMMJ7"$1MVTDPOUSPMNPEVMFTTVQQMZUIFDMPTFDVSSFOU

to the coil for approximately 200 milliseconds. Aerward, the coil current is

reduced to a lower hold-in value.

r 8IFOUIF*OUFMMJ7"$BOE*OUFMMJ7"$1MVTDPOUSPMNPEVMFTIBWFUIFDMPTF

command removed, the coil is de-energized, opening the contactor.

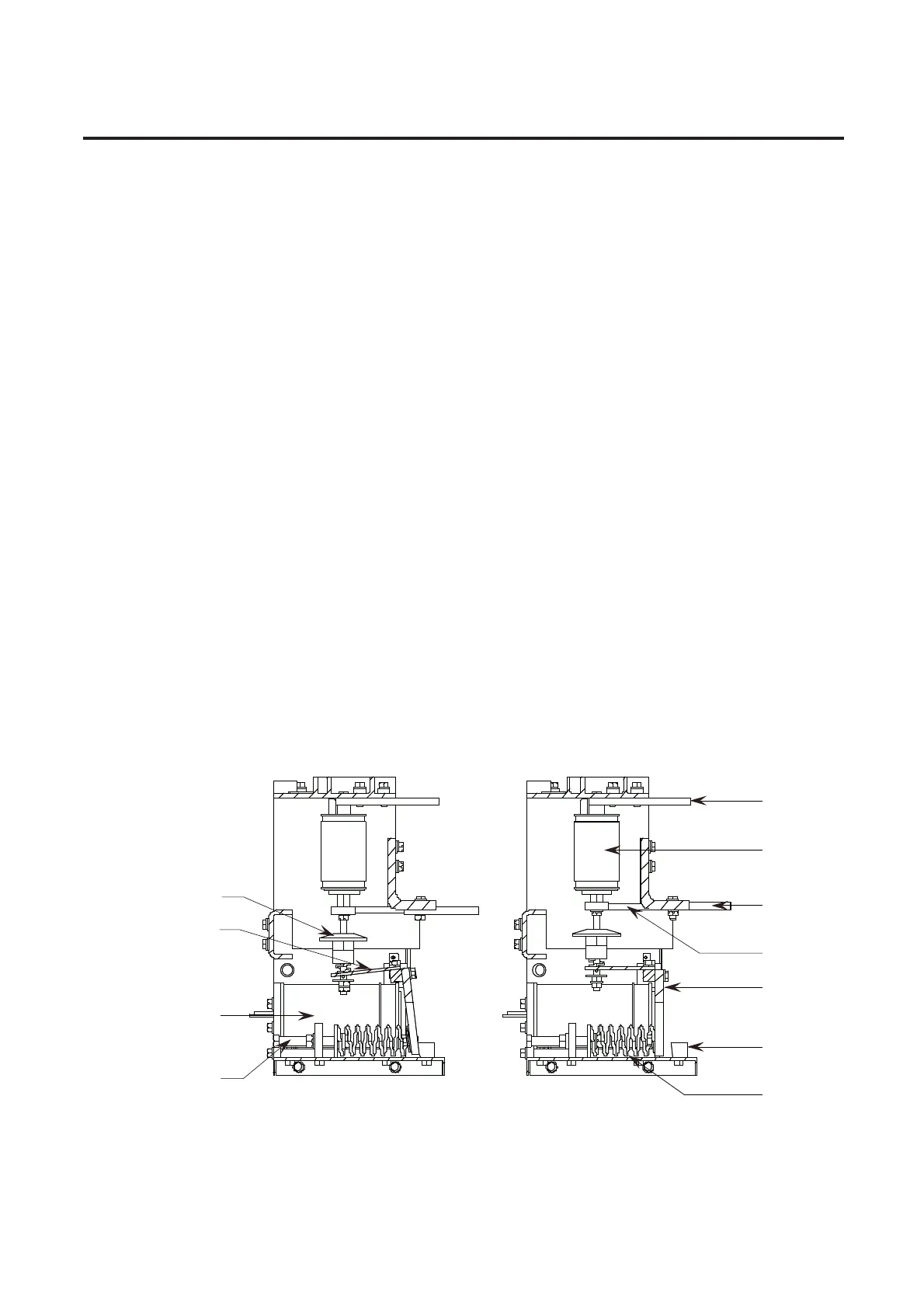

e mechanical latch contactor operates in much the same manner as the electri-

cally held version (see above) with a few exceptions:

r 0ODFUIFDPOUBDUPSJTDMPTFEBTQSJOHMPBEFENFDIBOJTNNPWFTBSPMMFS

against the armature plate to hold it against the electromagnetic core.

r ăFDPOUBDUPSDBOCFPQFOFEFMFDUSJDBMMZCZFOFSHJ[JOHBUSJQDPJMWJB*OUFM-

liVAC and IntelliVAC Plus 'open' output) which pulls the latch away from the

armature, or by a push button mounted on the power cell door that mechani-

cally releases the contactor.

Insulator

Return Spring

Compression Bolt

Magnet/Coil

Assembly

Actuator Plate

Line Terminal

Vacuum Bottle

Load Terminal

Flexible Bus

Armature Plate

and Shaft

Armature Stop

Return Spring

Figure 1.3 – Vacuum Contactor Operation

Loading...

Loading...