Chapter Troubleshooting

4-6

4

7. Measure resistance between pins 2 and 3. Resistance should be less than 100

ohms.

8. Measure resistance between pins 6 and 7. Resistance should be less than 100

ohms.

9. Measure resistance between pins 4 and 5. Resistance should be less than 250

ohms.

If the power module fails for any of the above tests, replace it.

The gold interconnection pins on the power module are protected with a special

contact lubricant. Do not clean or wipe these pins. This contact lubricant is

necessary for proper operation. Inspect each pin prior to assembly of the control

module. If the lubricant is missing, apply a thin film of the recommended contact

lubricant.

The Allen-Bradley approved contact lubricant is NYOGEL 759G, manufactured by

William F. Nye, Inc., Specialty Lubricants, New Bedford, MA 02742 U.S.A.

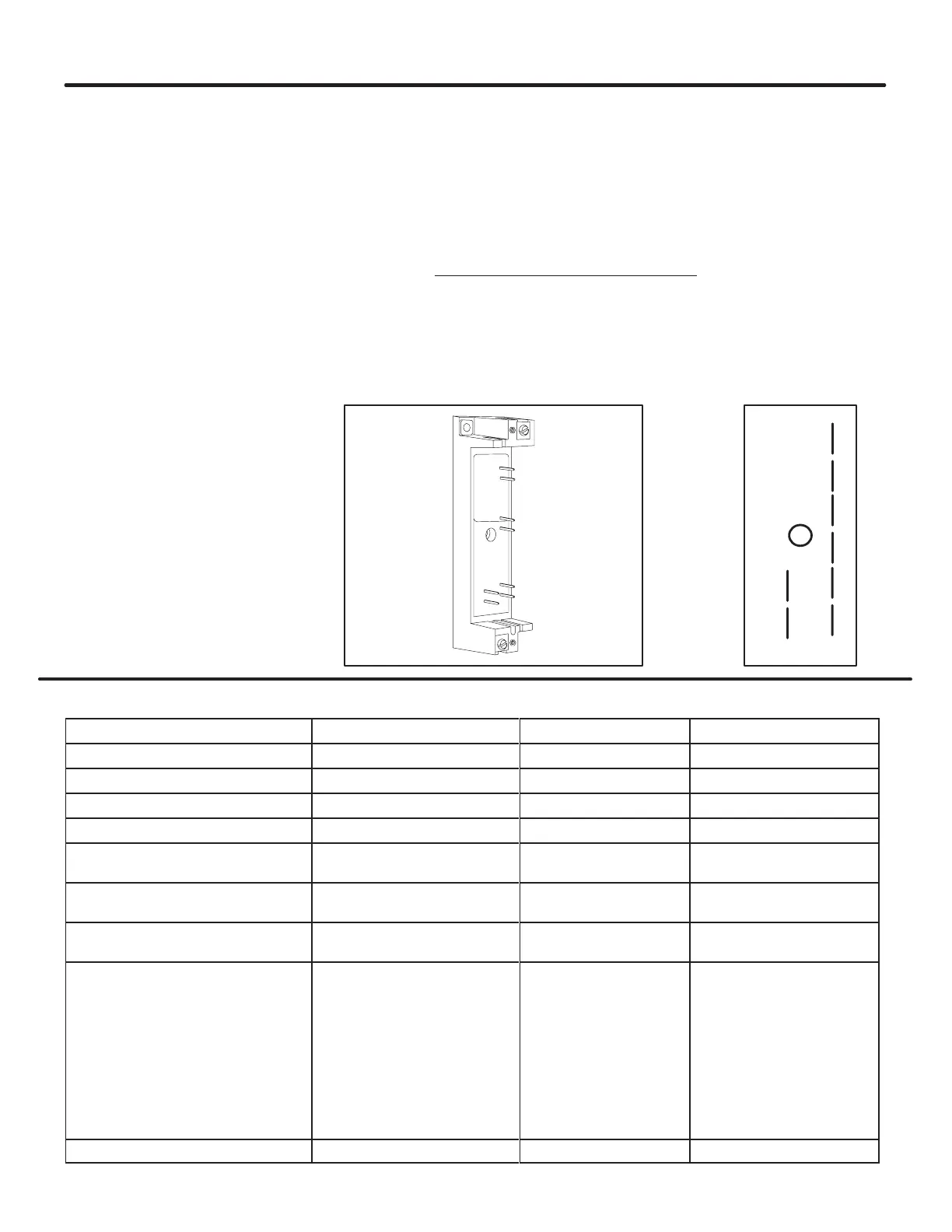

Figure 4.6 - Pin Locations for Power Module Resistance Check

2

3

7

6

1

4

8

5

Renewal Parts

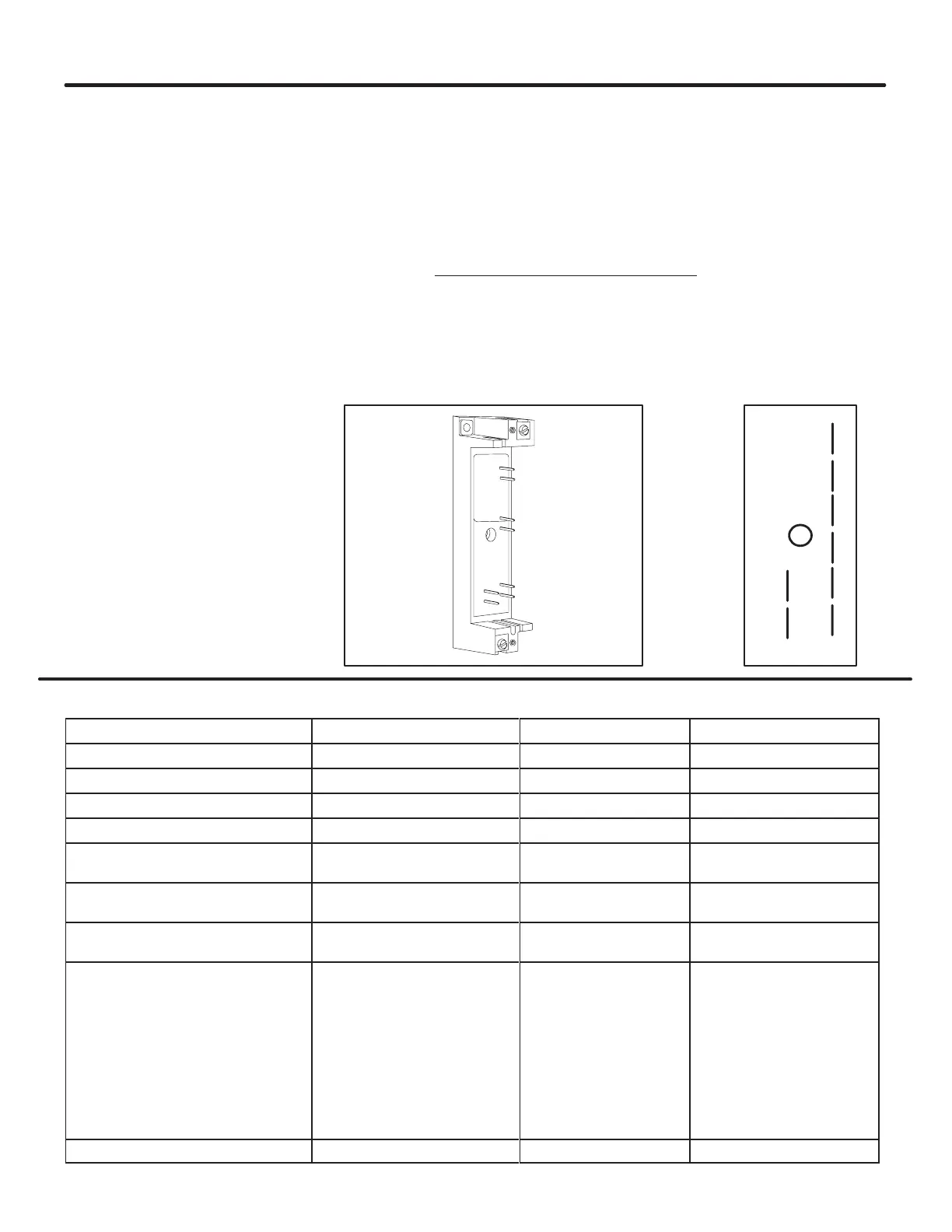

Description Controller Rating Line Voltage Rating Part Number

Control Module (Standard) All All 40888-899-01

Preset Slow Speed All All 40888-899-03

Soft Stop All All 40888-899-02

Pump Control All All 40888-899-14

SMB

Smart Motor Braking

24A-54A

97A-135A

All

40888-899-09

40888-899-10

Accu-Stop

24A-54A

97A-135A

All

40888-899-04

40888-899-05

Slow Speed with Braking

24A-54A

97A-135A

All

40888-899-15

40888-899-16

Power

Modules

24A

35A

54A

97A

135A

200-480

200-600

200-480

200-600

200-480

200-600

200-480

200-600

200-480

200-600

40382-899-02

40382-899-04

40382-899-03

40382-899-04

40382-899-03

40382-899-04

40382-806-01

40382-806-02

40382-806-03

40382-806-04

Fan 97A-135A All 40382-807-01

Power Module

Resistance Check

(continued)

Loading...

Loading...