Chapter Troubleshooting

4-4

4

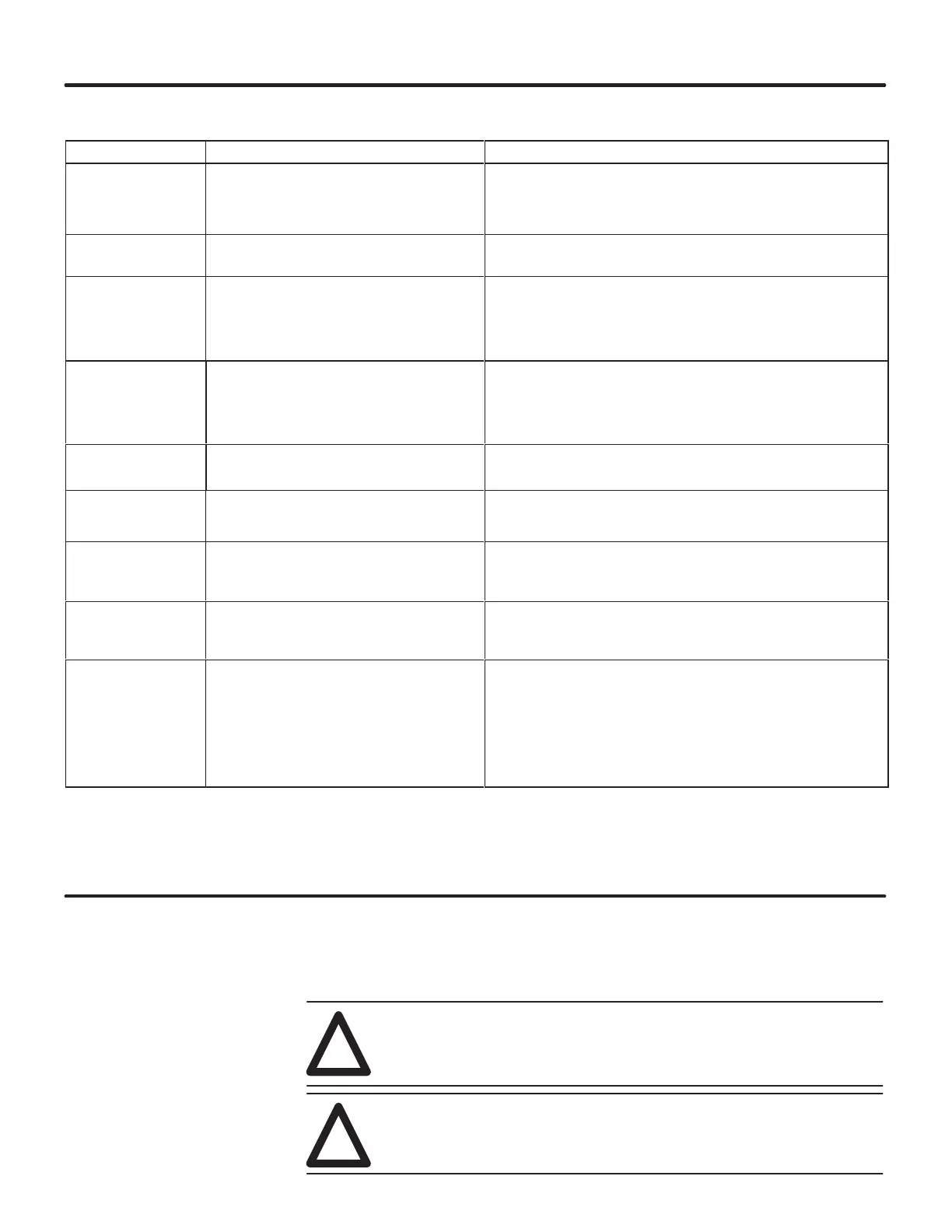

Figure 4.4 - Miscellaneous situations

Symptom Possible Causes Remedy

Motor current and

voltage fluctuates

with steady load

• Check motor

• Energy Saver

• Verify the application of standard squirrel cage induction motor

• Set Energy Saver Off (DIP switch #5 to Off) then restart If

problem stops, replace control module; If problems persists,

shut off ALL power to controller and check connections

Erratic operation

• Loose connections • Shut off ALL power to controller and check for loose

connections

Accelerates too fast

• Incorrect starting time

• Incorrect kickstart

• Incorrect initial torque

• Incorrect current limit setting

• Increase starting time/Lower initial torque

• Lower kickstart

• Lower initial torque

• Decrease current limit

Accelerates too slow

• Incorrect starting time

• Incorrect kickstart

• Incorrect initial torque

• Incorrect current limit setting

• Decrease starting time

• Increase kickstart time

• Increase initial torque

• Increase current limit

Fan doesn’t operate

(97A and 135A only)

• Fan not wired properly • Check fan wiring

• Replace fan if necessary

Motor stops too

quickly with soft stop

option

• Incorrect settings • Verify that DIP switch settings are correct

Motor stopping time

is too slow with soft

stop option

• Incorrect settings

• Misapplication

• Verify that DIP switch settings are correct

• The soft stop option is intended for loads that stop suddenly

when voltage is removed from the motor

Motor surges still

occur with soft stop

option

• Misapplication • The soft stop option is intended for loads that stop suddenly

when voltage is removed from the motor

• Refer to Publication 150-806 – Pump Control Option

Motor overheats ➀

• Duty Cycle • Preset Slow Speed Option: Extended operation reduces motor

cooling efficiency. Consult motor manufacturer for limits of

operation

• Smart Motor Brake Option: Check duty cycle ➁

• Accu-Stop Option: Extended operation at the preset slow

speed level reduces motor cooling efficiency. Consult motor

manufacturer for limits of operation. Verify maximum inertia

limits ➁

➀ When applying SMB, Accu-Stop, Preset Slow Speed and Slow Speed with braking, it may be necessary in some applications to consult with

motor manufacturer on motor heating due to the duty cycle, high load inertia or other application parameters.

➁ Depending on the application, the SMB Smart Motor Braking, Accu-Stop, and Slow Speed with Braking options may cause some vibration or noise

during the stopping cycle and this may be minimized by lowering the braking current. If this is a concern in your application, consult the factory

prior to applying these options.

The control module is not intended for field repair. The entire module must be

replaced in the event of failure. The following procedure must be followed before

unplugging the control module.

WARNING: To avoid shock hazard, disconnect main power before

working on the controller, motor, or control devices such as Start/Stop

push buttons.

!

CAUTION: Make sure that wires are properly marked and DIP switch

settings are recorded.

!

Control Module

Removal

Loading...

Loading...