160 Rockwell Automation Publication 520-UM001I-EN-E - July 2016

Chapter 4 Troubleshooting

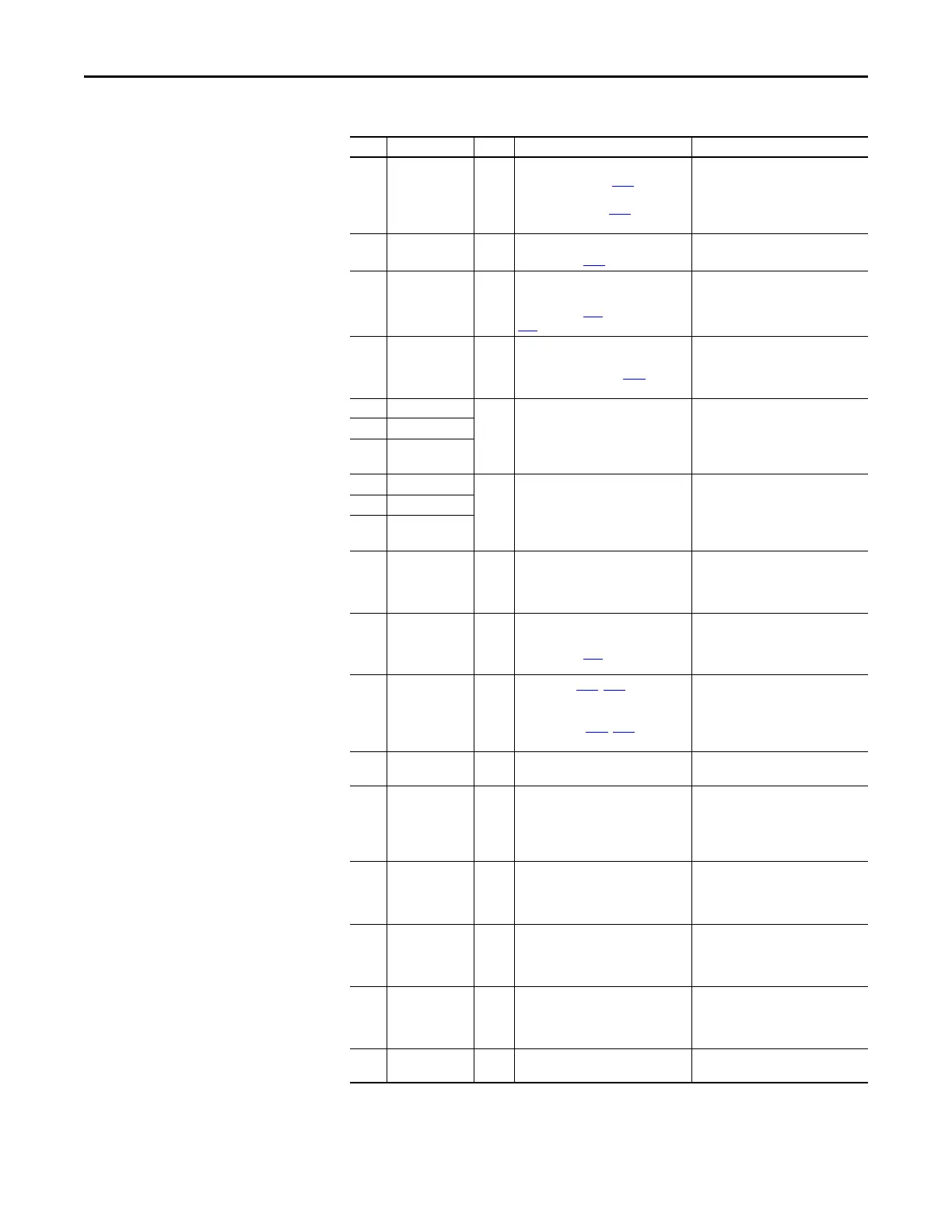

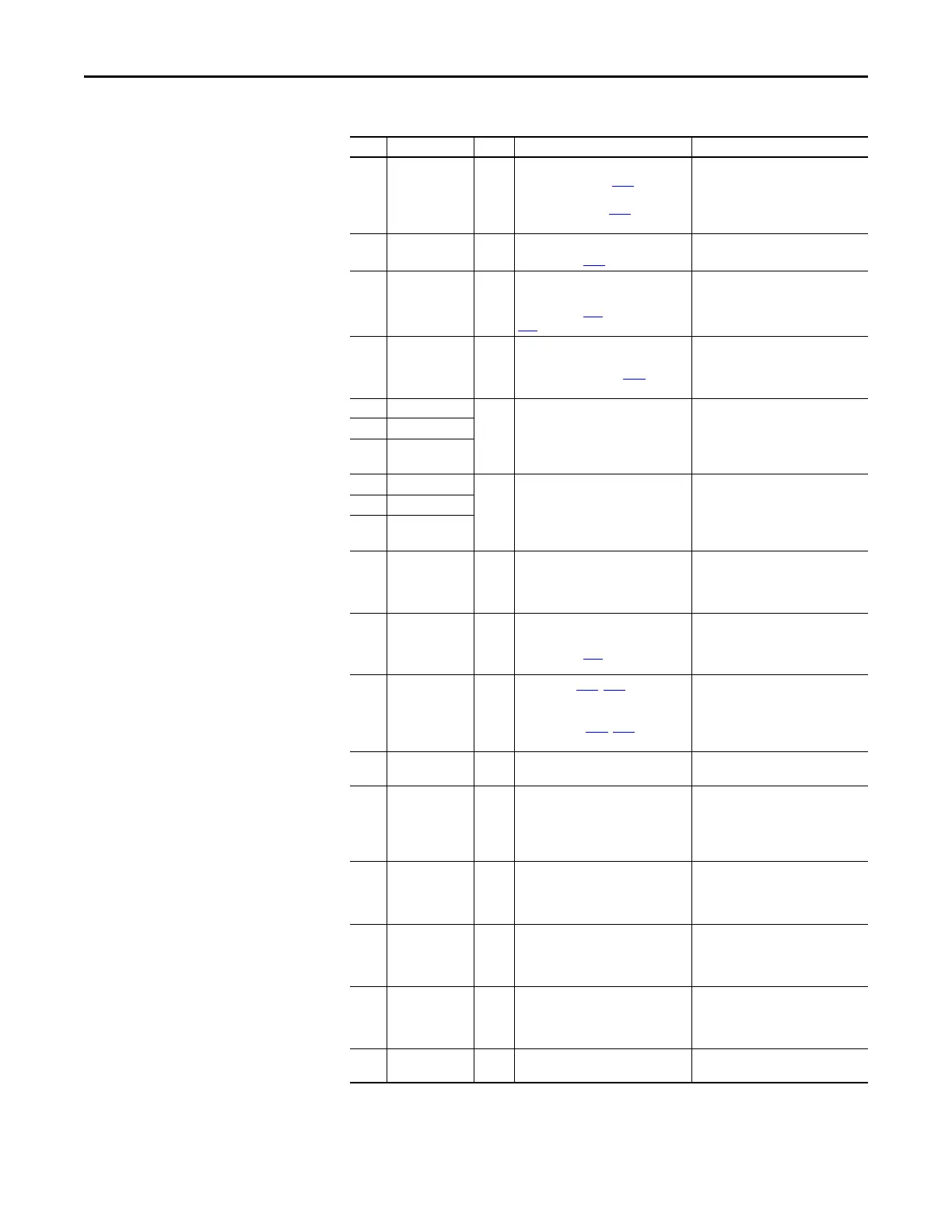

F015

(1)

Load Loss 2 The output torque current is below the

value programmed in A490 [Load Loss

Level] for a time period greater than the

time programmed in A491 [Load Loss

Time].

• Verify connections between motor

and load.

• Verify level and time requirements

F021 Output Ph Loss 1 Output Phase Loss (if enabled).

Configure with A557

[Out Phas Loss En].

• Verify motor wiring.

• Verify motor.

F029 Analog In Loss 1 An analog input is configured to fault on

signal loss. A signal loss has occurred.

Configure with t094

[Anlg In V Loss] or

t097 [Anlg In mA Loss].

• Check for broken/loose connections

at inputs.

• Check parameters.

F033 Auto Rstrt Tries 2 Drive unsuccessfully attempted to reset

a fault and resume running for the

programmed number of A541

[Auto

Rstrt Tries].

Correct the cause of the fault and

manually clear.

F038 Phase U to Gnd 2 A phase to ground fault has been

detected between the drive and motor

in this phase.

• Check the wiring between the drive

and motor.

• Check motor for grounded phase.

• Replace drive if fault cannot be

cleared.

F039 Phase V to Gnd

F040 Phase W to Gnd

F041 Phase UV Short 2 Excessive current has been detected

between these two output terminals.

• Check the motor and drive output

terminal wiring for a shorted

condition.

• Replace drive if fault cannot be

cleared.

F042 Phase UW Short

F043 Phase VW Short

F048 Params Defaulted 1 The drive was commanded to write

default values to EEPROM.

• Clear the fault or cycle power to the

drive.

• Program the drive parameters as

needed.

F059

(1)

Safety Open 1 Both of the safety inputs (Safety 1,

Safety 2) are not enabled.

Configure with t105 [Safety Open En].

• Check safety input signals. If not

using safety, verify and tighten

jumper for I/O terminals S1, S2 and

S+.

F063 SW OverCurrent 1 Programmed A486, A488 [Shear Pinx

Level] has been exceeded for a time

period greater than the time

programmed in A487, A489 [Shear Pin x

Time].

• Verify connections between motor

and load.

• Verify level and time requirements.

F064 Drive Overload 2 Drive overload rating has been

exceeded.

Reduce load or extend Accel Time.

F070 Power Unit 2 Failure has been detected in the drive

power section.

• Check maximum ambient

temperature has not been exceeded.

• Cycle power.

• Replace drive if fault cannot be

cleared.

F071 DSI Net Loss 2 Control over the Modbus or DSI

communication link has been

interrupted.

• Cycle power.

• Check communications cabling.

• Check Modbus or DSI setting.

• Check Modbus or DSI status.

F072 Opt Net Loss 2 Control over the network option card’s

remote network has been interrupted.

• Cycle power.

• Check communications cabling.

• Check network adapter setting.

• Check external network status.

F073

(1)

EN Net Loss 2 Control through the embedded

EtherNet/IP adapter has been

interrupted.

• Cycle power.

• Check communications cabling.

• Check EtherNet/IP setting.

• Check external network status.

F080 Autotune Failure 2 The autotune function was either

cancelled by the user or failed.

Restart procedure.

Fault Types, Descriptions and Actions

No. Fault Type

(2)

Description Action

Loading...

Loading...