Chapter 1 FactoryTalk Batch introduction

16

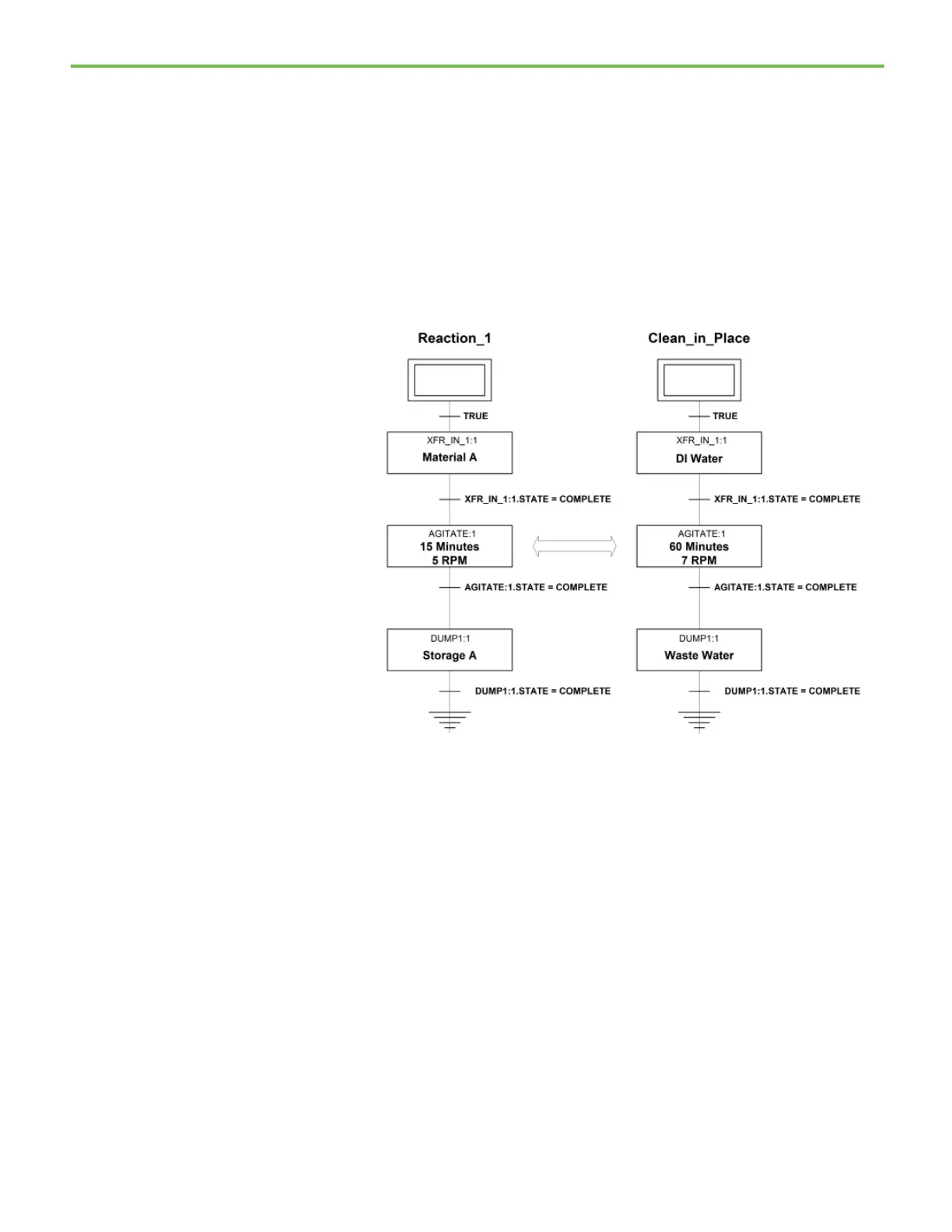

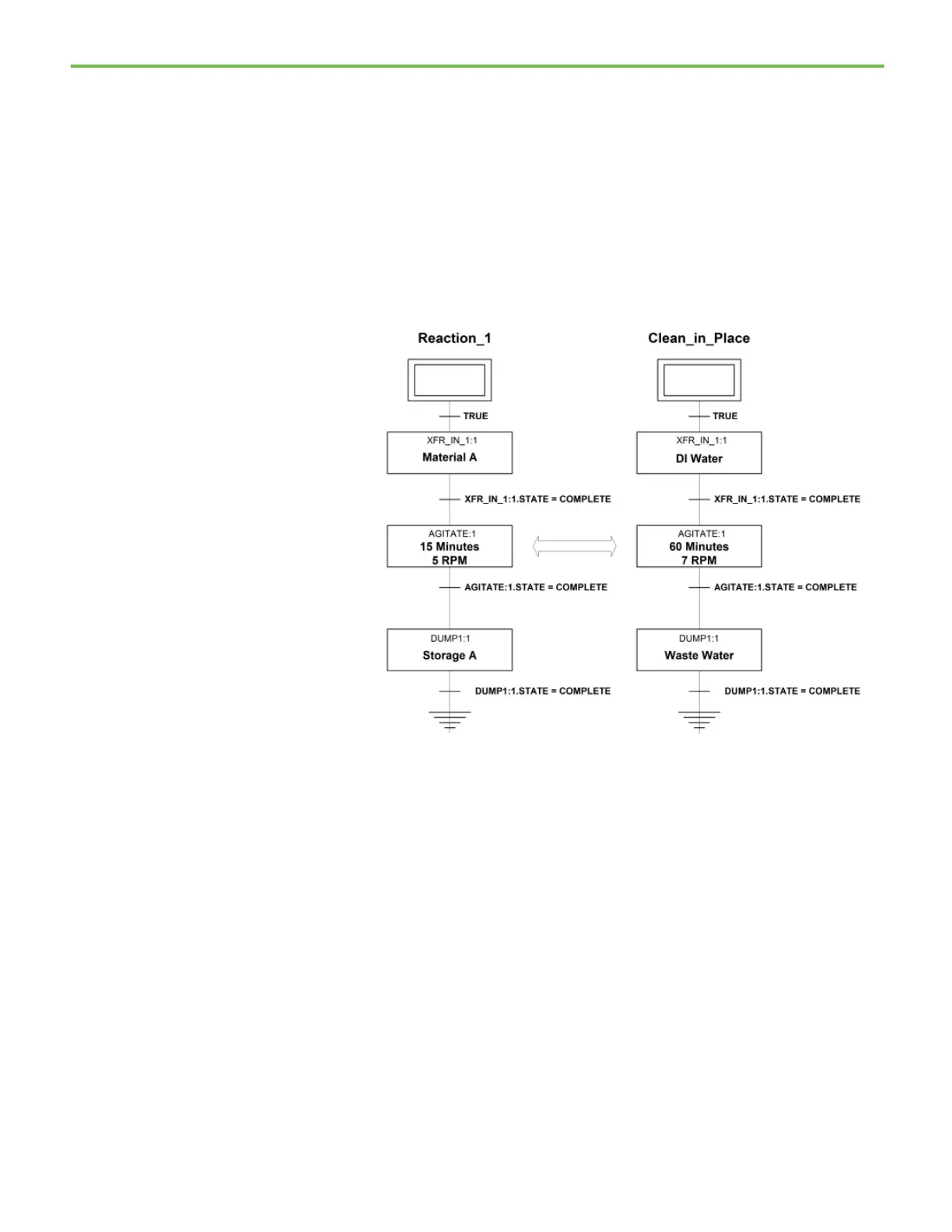

To continue the example in the FactoryTalk Batch Recipe Editor, you create

two operations, Reaction_1 and Clean_In_Place, which are shown below. The

Reaction_1 operation transfers Material A into the reactor, agitates the

contents for 15 minutes at 5 RPM, and then dumps the contents into Storage

Unit A. The Clean_in_Place operation transfers water into the reactor, agitates

the contents for 60 minutes at 7 RPM, and then dumps the contents as Waste

Water.

Both operations use the same phases but in a different way. You control how

the phase operates through the use of parameters, such as speed and time as

shown in the AGITATE:1 phase.

For more information regarding how FactoryTalk Batch applies the ISA S88.01

concepts, contact your Rockwell Sales Representative. For a copy of the S88.01

document, write to: ISA, 67 Alexander Drive, P.O. Box 12277, Research

Triangle Park, NC 27709

FactoryTalk Batch organizes information for a number of different

occupational roles:

• Process Engineer: Uses the FactoryTalk Batch Equipment Editor to

create an area model that captures all capabilities of the specific plant.

• Control Systems Engineer: Understands the specific control system

being used and links the control system with FactoryTalk Batch.

• Formulator: Uses the FactoryTalk Batch Recipe Editor to create master

recipes that run against the area model of the plant.

Editor example

Batch?

Loading...

Loading...