24

Reference Manual

00809-0100-4809, Rev DA

Section 2: Installation

September 2015

Installation

Step 3: Weld the mounting hardware

1. Center the Pak-Lok body over the mounting hole, gap

1

/16-in. (1.5 mm) and place four

1

/4-in. (6 mm) tack welds at 90° increments.

2. Check alignment of the Pak-Lok body both parallel and perpendicular to the axis of

flow. If alignment of mounting is within tolerances (see Figure 2-15), finish weld per

local codes. If alignment is outside of specified tolerance, make adjustments prior to

finish weld.

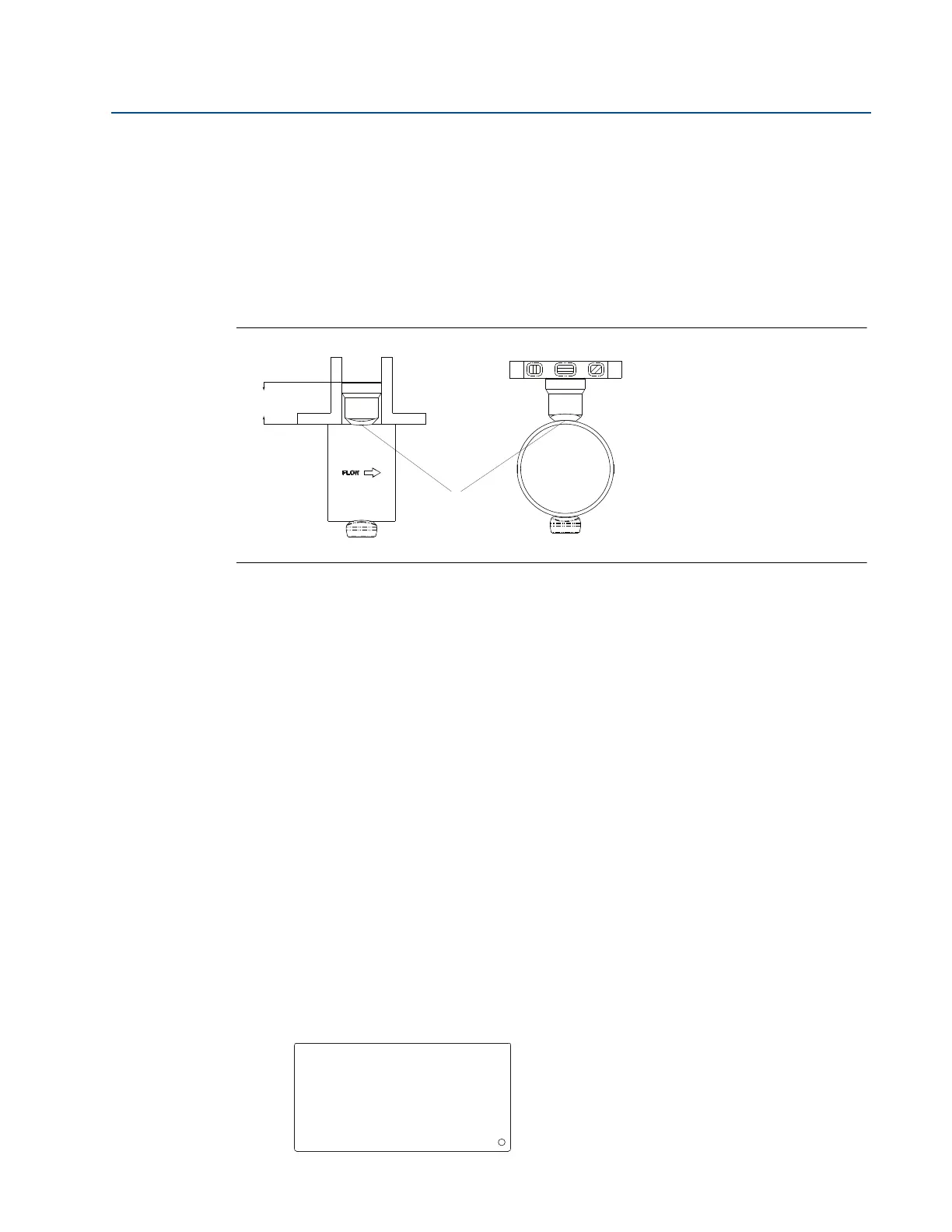

Figure 2-15. Alignment

A. Tack welds

3. If opposite side support is being used, center the fitting for the opposite side support

over the opposite side hole, gap

1

/16-in. (1.5 mm) and place four

1

/4-in. (6 mm) tack

welds at 90° increments. Insert the sensor into the mounting hardware. Verify that the

tip of the bar is centered in the opposite side fitting and verify that the plug will fit

around bar. If the bar is centered in the fitting and plug fits around the bar, finish weld

per local codes. If the alignment of the bar does not allow enough clearance to insert

the opposite side plug, make the necessary adjustments prior to making the finish

weld.

4. To avoid serious burns, allow the mounting hardware to cool before continuing.

Step 4: Insert Annubar sensor

After the mounting hardware has cooled, use the following steps for installation.

1. Thread studs into the Pak-Lok body.

2. To ensure the flowmeter contacts the opposite side wall, mark the tip of the sensor with

a marker. (Do not mark if the sensor was ordered with special-cleaned option code P2 or

PA.)

3. Insert the flowmeter into the Pak-lok body until the sensor tip contacts the pipe wall (or

support plug). Rotate the flowmeter back and forth.

4. Remove the flowmeter.

LMH

A

Serial No. Date

Model

Customer Tag

Pipe I.D. Wall

Max. Allow FlowRate

Max. Insert/Retract Flow

Max. Press. @ Temp

Span (20mA)

00-370000-2X1 Rev. AC

Loading...

Loading...