8

• Always keep bolts tight. Check periodically.

•Always assure arm stop bolts are in place.

• Always keep lift components clean.

• Always, if oil leakage is observed, call local service

representative.

• Daily: Check cables and sheaves for wear. If parts are worn,

call local service representative.

• Daily: Inspect adapters for damage or excessive wear. If

parts are worn, call local service representative.

•Daily: Check for permanent deformation to the latches. If

present, call local service representative to replace parts.

• Monthly: Check equalizer cable tension. If parts are worn,

call local service representative.

• Monthly: Check overhead sensor for function.

• Every3Months: Check anchor bolts for tightness. Anchors

should be torqued to 122Nm (12.4kg-m).

• Every6months:Checkuidlevelofliftpowerunitandrellto

proper level in level indicator with lift fully lowered.

• Replace all decals on the lift if unable to read or missing.

Reorder labels from Rotary Lift.

• Monthly: Clean and check base of lift. Remove any rust and

touch-up with paint.

OPERATOR INSPECTION & MAINTENANCE

MAINTENANCE AUTHORIZED BY OPERATOR

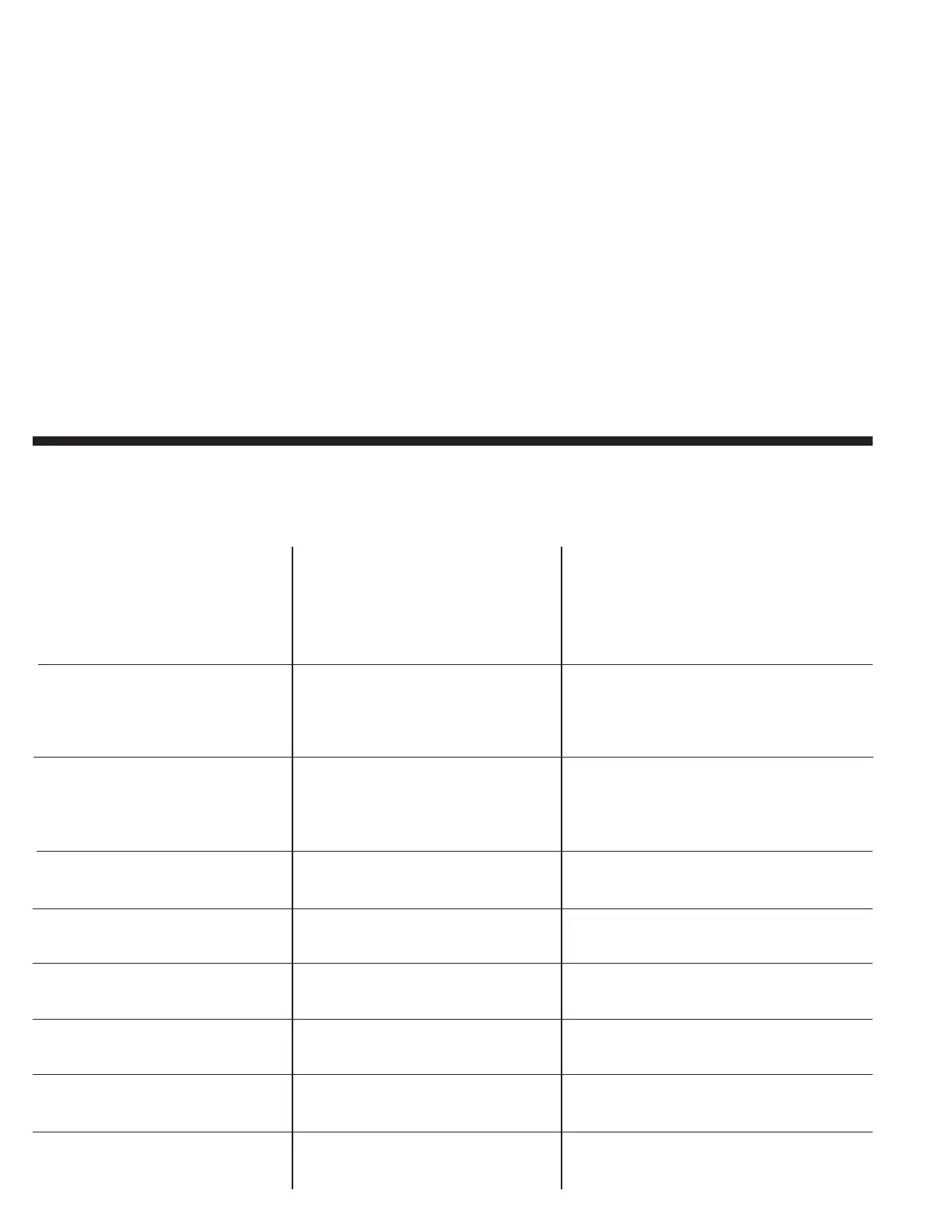

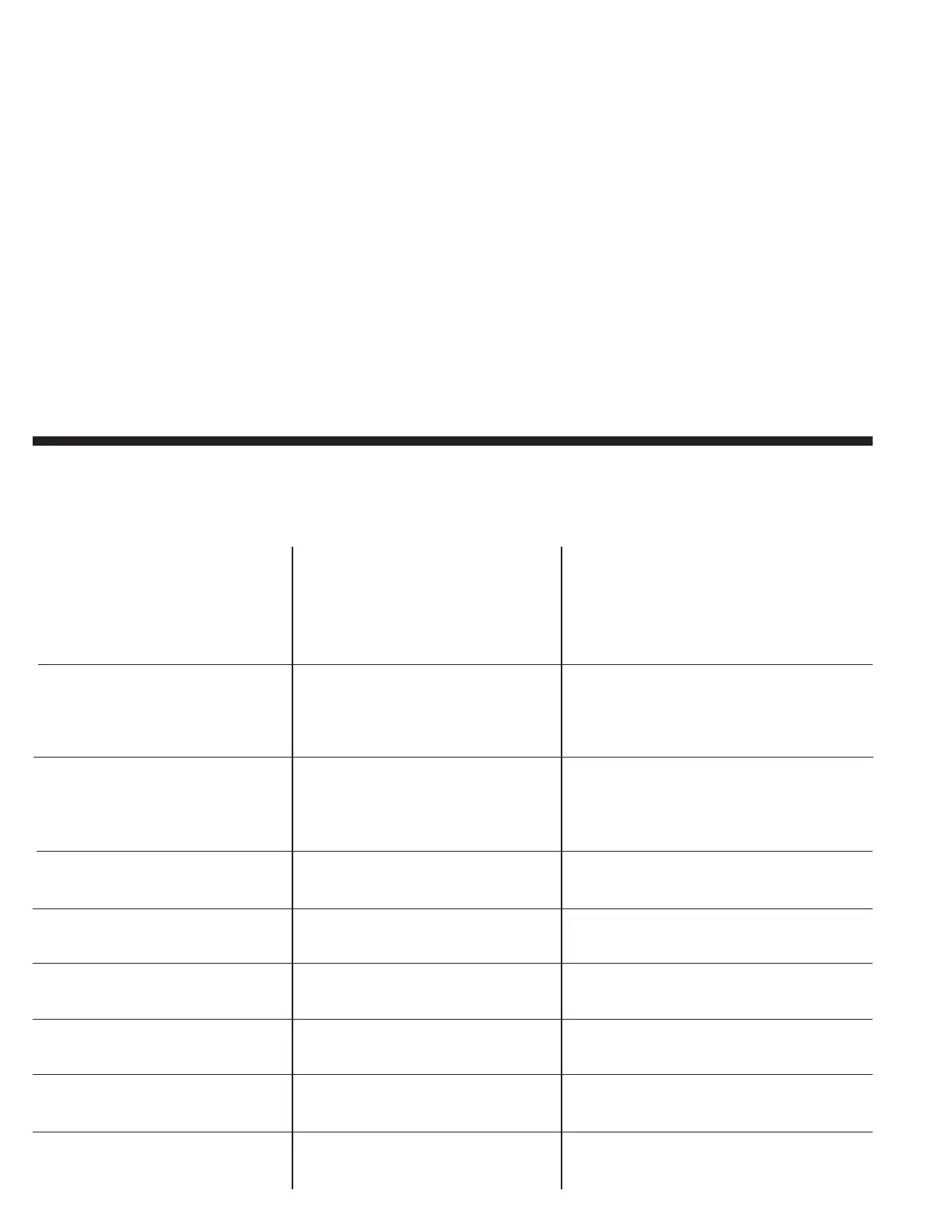

Cause

1. Blown fuse or circuit breaker.

1. Low oil level.

1. Overloading lift.

See Remedy

See Remedy

See Remedy

See Remedy

See Remedy

See Remedy

Remedy

1. Replace blown fuse or reset circuit

breaker.

2. Contact service representative for further

assistance.

1. Fill tank to MIN___ mark with ISOVG32

hydraulic oil or Dexron III ATF.

2. Contact service representative for further

assistance.

1. Check vehicle weight and/or balance

vehicle weight on lift.

2. Contact service representative for further

assistance.

1. Contact service representative for further

assistance.

1. Contact service representative for further

assistance.

1. Contact service representative for further

assistance.

1. Contact service representative for further

assistance.

1. Contact service representative for further

assistance.

1. Contact service representative for further

assistance.

Trouble

Motor does not run.

Motor runs but will not raise lift.

Motor runs—raises unloaded lift but

will not raise vehicle.

Lift slowly settles down.

Slow lifting speed or oil blowing out

filler breather cap.

Lift going up unlevel.

Anchors will not stay tight.

Locking latches do not engage.

Locking latches do not disengage.

TROUBLE SHOOTING FOR OPERATORS

FOR M SERIES LIFTS

Loading...

Loading...