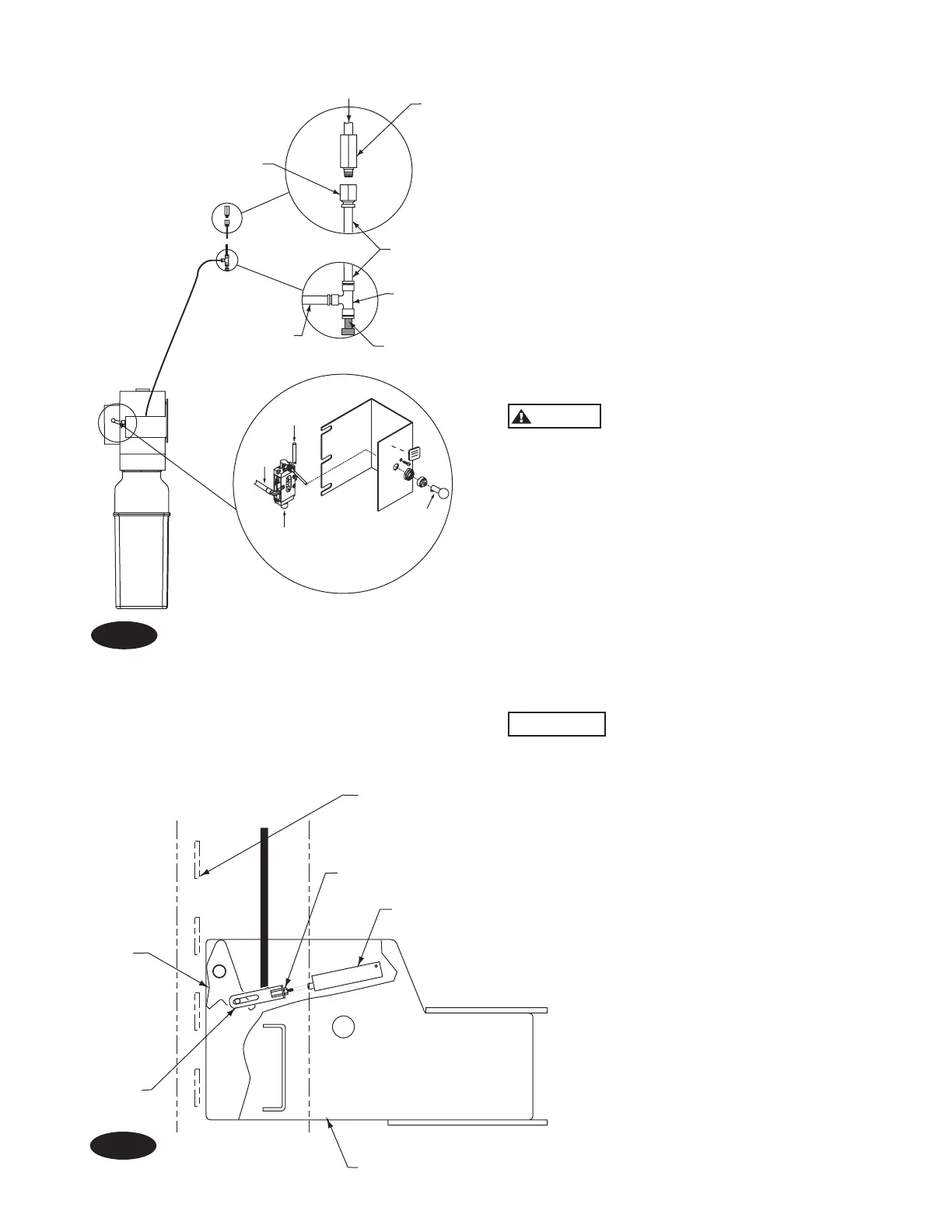

13

Latch

Jam Nut

Air Cylinder

Slotted

Bracket

13. Bleeding: Raise and lower lift (6) times. The cylinder is self-

bleeding. After bleeding system, replace fill vent screw.

Note: Some fluid may be exhausted from the cylinder breather

vent during bleeding of the system.

14. Pressure Test: To pressure test, run lift to full rise and run

motor for approximately five (5) seconds. Stop and check all hose

connections. Tighten or reseal if required. Lower lift. Check fluid

level in reservoir. Fill as required per instrustions in Step 11.

15. Final Adjustmemt:

A. Load vehicle, such as a 3/4 ton pickup or van onto lift.

B. Raise lift as high as it will travel (full height). As the lift is

raised, note in which rear column locking latch clicks into

slot at same time as the first column.

C. Adjust cable in other rear column so that its

locking latch clicks into slot at same time as the

first column.

There must be a minimum of two (2) threads

above the nut after adjustment.

D. Raise lift again. This time listening for the first front latch

to click into place. Adjust this simultaneously with the rear

columns.

E. Do the same for the remaining front column.

F. Tighten jam nuts and lower lift.

Note: Latches may not click in at the same time when vehicle is

being raised. They should be closed. Be sure all four (4) corners

have passed the locking latch bar slot before lowering lift on

locking latches.

Note: Replace any missing hardware with Grade 5 or higher.

Cotter pins are usually good for one time use

only. Replace any cotter pin, if removed, with new cotter pin.

16. Upon completion of the assembly of the lift, the lift is to

be operated to assure proper function. Observe for locks

operating in all locking positions, each side lifts equally,

hydraulics do not leak, all electrical controls function as

labeled, all pneumatics are functional and leak free, ramps

rotate freely (if applicable), and proper clearances with all

items in bay have been maintained.

Operate the lift with a typical vehicle and observe to assure

the same items for proper functioning.

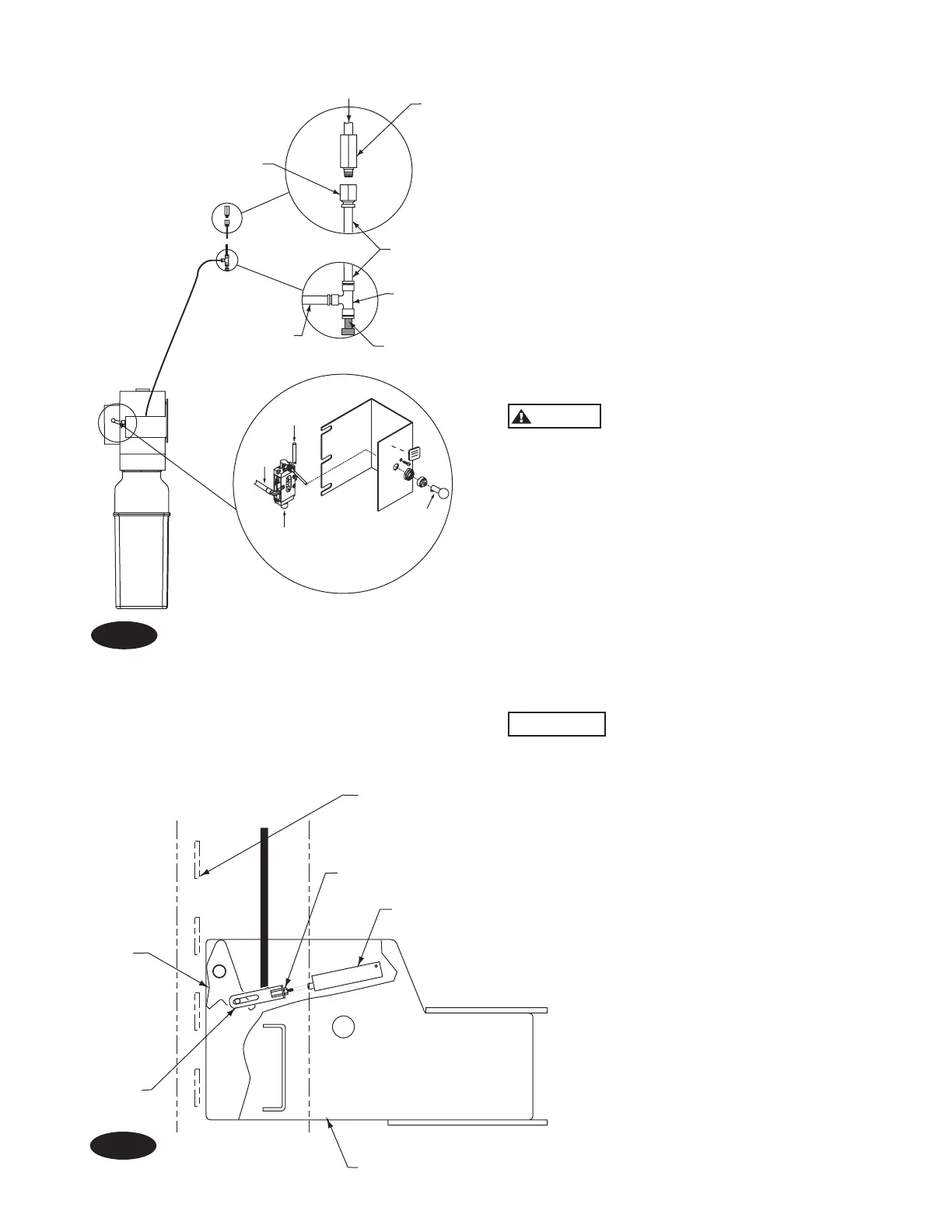

Fig. 24

Fig. 25

3

/

8

” Air

Line

Connect Air Supply to Air Valve

Filter

Air Supply

Female

Connector

Reducing

Tee

Plastic

Plug

Air Valve

1

/

4

” Air Line

Air

Output

Air

Input

Push

Lever

Loading...

Loading...