APPENDIX A - Stop Bolt Adjustment

Page 10 of 12

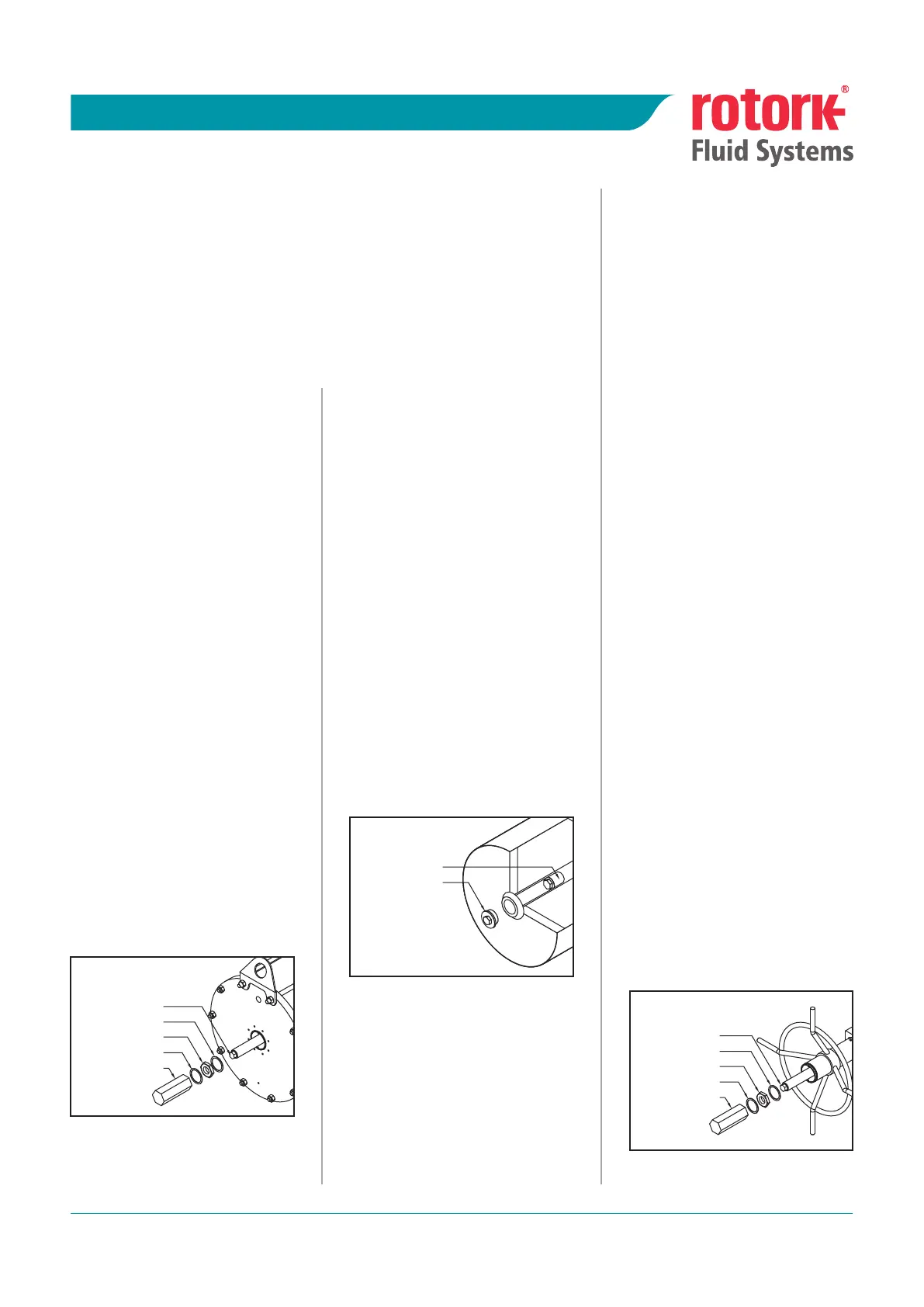

1.2 Spring Canister

(See figure 2)

1.2.1 Remove the spring stop cap.

1.2.2 Depressurize the cylinder to

allow the spring to relax.

Failure to do so may result in

damage to the actuator!

1.2.3 Adjust the spring stop in/out as

desired.

1.2.4 Pressurize to outboard side of

power cylinder sufficiently to

induce a complete stroke of

the actuator and then check

the stop position.

1.2.5 Repeat steps 1.2.2 - 1.2.4 as

necessary to achieve desired

degree of travel.

1.2.6 Once the desired position is

achieved, replace spring stop

cap.

1.1 Pneumatic/Hydraulic

Cylinder (See figure 1)

1.1.1 Remove stop bolt cover.

1.1.2 Loosen stop nut.

1.1.3 Apply pressure to outboard

side of cylinder to remove load

from stop bolt. Failure to do so

may result in damage to the

actuator!

1.1.4 Adjust stop bolt in/out as

desired.

1.1.5 Remove pressure from cylinder

to verify stop position.

1.1.6 Repeat steps 1.1.3 - 1.1.5 as

necessary to achieve desired

degree of travel.

1.1.7 Once desired position is

achieved, tighten stop nut,

ensuring sealing washer is

properly centered on the shaft

and fitted in the machined

recess in the flange.

1.1.7 Re-install stop cover, ensuring

sealing washer is properly

centered on the shaft and

fitted in the machined recess in

the stop cover.

1.0 Overview

All RFS G Range actuators (ie., GP, GH, GO and HPG) incorporate adjustable stops

to limit the degree of travel in both directions. Steps are outlined below for

adjustment of the three stop configurations: pneumatic/hydraulic cylinder, spring

cartridge and, jackscrew.

Actuators may be damaged by improper adjustment procedure. Strictly follow

the instructions as outlined below with particular attention to the warnings is

steps 1.1.3, 1.2.2, 1.3 and 1.3.3.

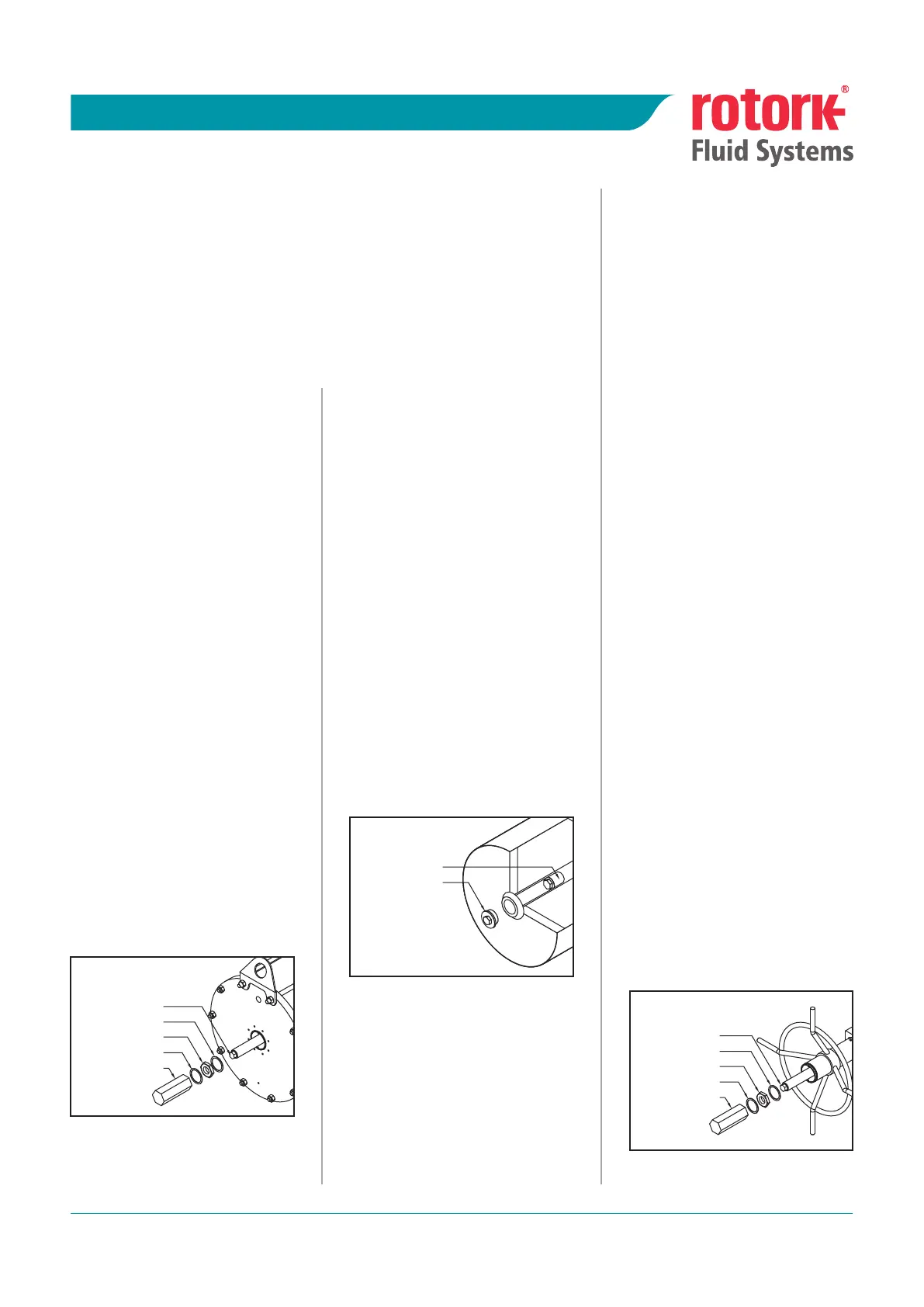

1.3 Jackscrew

(See figure 3)

Note: The jackscrew is not designed

to function as a travel stop.

Stroking the actuator against

the jackscrew may damage it.

1.3.1 Remove stop bolt cover.

1.3.2 Loosen stop nut.

1.3.3 Turn jackscrew fully in to

compress spring and remove

any load from the stop. Failure

to do so may result in damage

to the actuator!

On fail close actuators, this is

d o n e b y t u r n i n g t h e

handwheel anti-clockwise.

On fail open actuators, this is

d o n e b y t u r n i n g t h e

handwheel clockwise.

1.3.4 Adjust stop bolt in/out as

desired.

1.3.5 Back jackscrew out (opposite

direction of as determined in

1.3.3) until seated against stop

screw to verify stop position.

1.3.6 Repeat steps 1.3.3 - 1.3.5 as

necessary to achieve desired

degree of travel.

1.3.7 Once desired position is

achieved, tighten stop nut,

ensuring sealing washer is

properly centered on the shaft

and fitted in the machined

recess.

1.3.8 Re-install stop cover, ensuring

sealing washer is properly

centered on the shaft and

fitted in the machined recess in

the stop cover.

figure 2

figure 1

figure 3

STOP SCREW

STOP NUT

SEALING WASHER

SEALING WASHER

STOP BOLT COVER

STOP SCREW

STOP NUT

SEALING WASHER

SEALING WASHER

STOP BOLT COVER

SPRING STOP

SPRING STOP CAP

INSTALLATION AND MAINTENANCE

GP RANGE

Publication F130E

Date of issue 04/08

Loading...

Loading...