Hardware Installation and Reference Guide Preparing for Installation

16

2.2.5 Cleanliness Requirements

Dust poses a major threat to the switch. The indoor dust takes on a positive or negative static electric charge

when falling on the switch, causing poor contact of the metallic joint. Such electrostatic adhesion may occur

more easily when the relative humidity is low, not only affecting the service life of the switch, but also causing

communication faults. The following table describes the requirements for the dust content and granularity in the

equipment room.

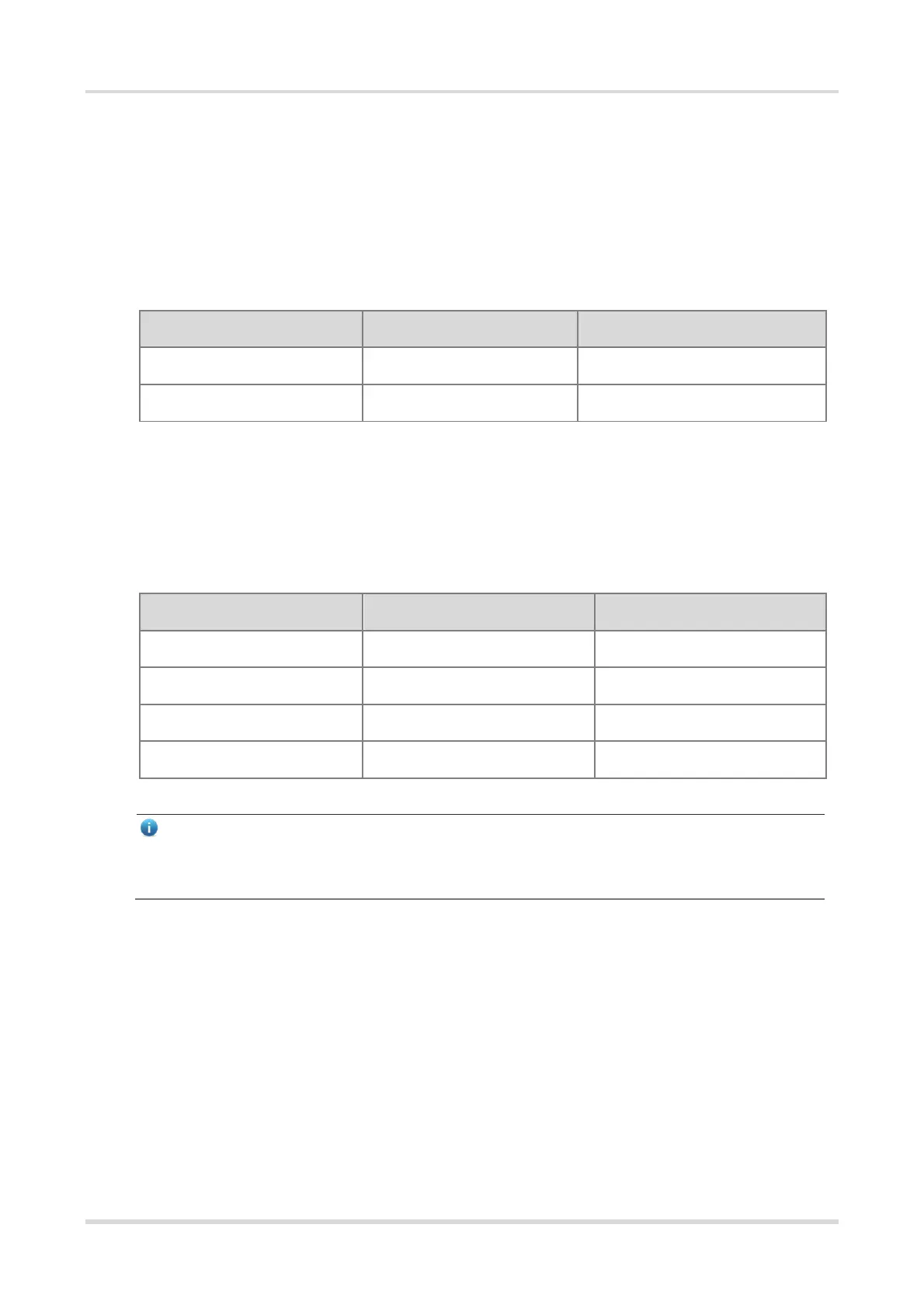

Table 2-2 Requirements for Dust

Dust particles (diameter ≥ 0.5 μm)

Dust particles (diameter ≥ 5 μm)

Apart from dust, the salt, acid, and sulfide in the air in the equipment room must meet strict requirements. These

harmful substances will accelerate metal corrosion and component aging. Therefore, the equipment room should

be properly protected against the intrusion of harmful gases, such as sulfur dioxide, hydrogen sulfide, nitrogen

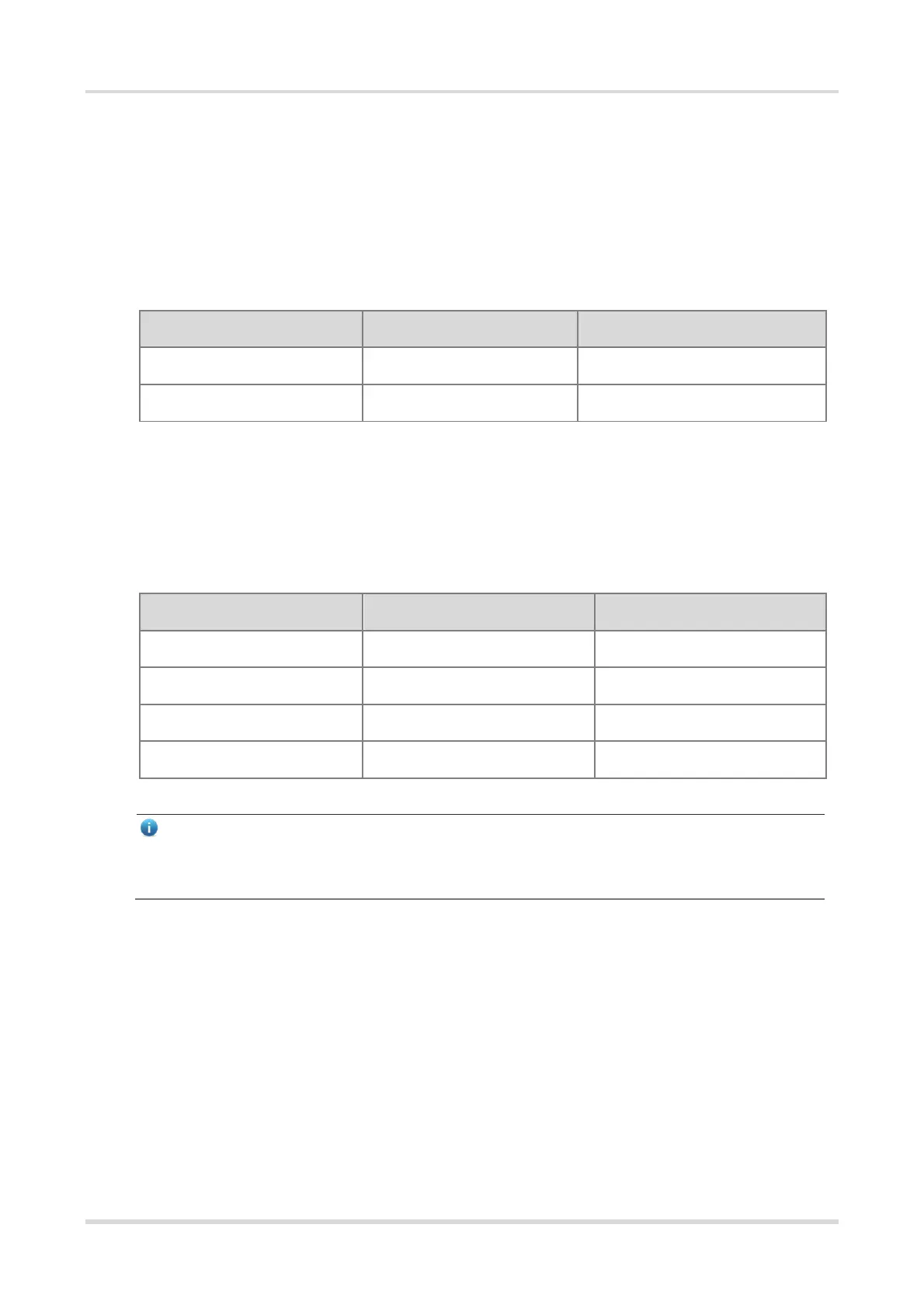

dioxide, and chlorine gas. The following table lists limit values for harmful gases.

Table 2-3 Requirements for Gases

Note

Average refers to the average value of harmful gases measured in one week. Maximum refers to the upper

limit of harmful gases measured in one week, and the maximum value lasts up to 30 minutes every day.

2.2.6 Grounding Requirements

A proper grounding system is the basis for stable and reliable running and is indispensable for preventing

lightning strikes and interference. Carefully check the grounding conditions at the installation site according to

the grounding specifications, and complete grounding properly based on the actual situation.

⚫ Safe Grounding

Ensure that the cabinet and power distribution device are securely grounded when the device uses the AC power

supply. Otherwise, electric shock may occur when the insulation resistance between the power supply inside the

device and the chassis becomes small.

Loading...

Loading...