START-UP

Axio Lab.A1 Installing standard components Carl Zeiss

04/2013 430037-7144-001 53

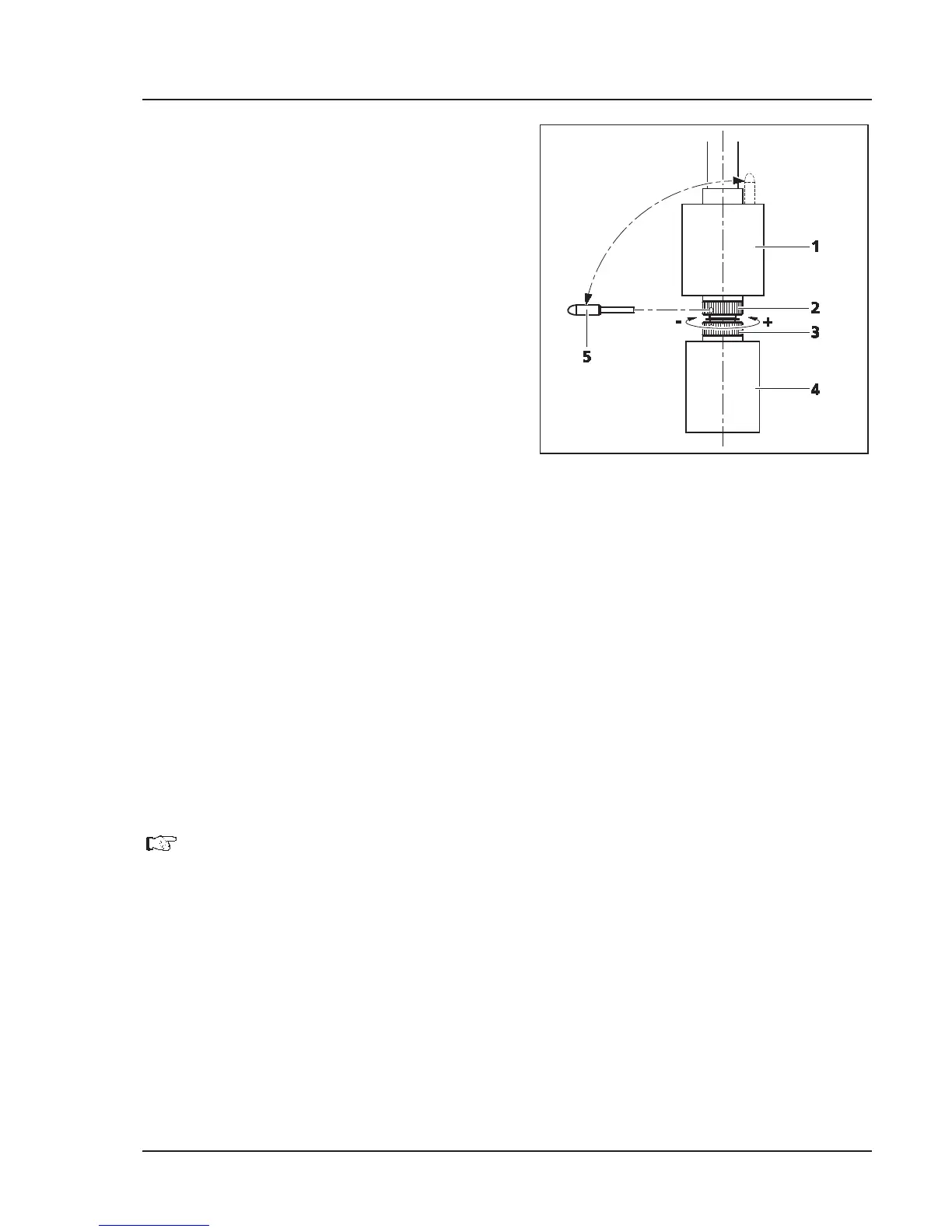

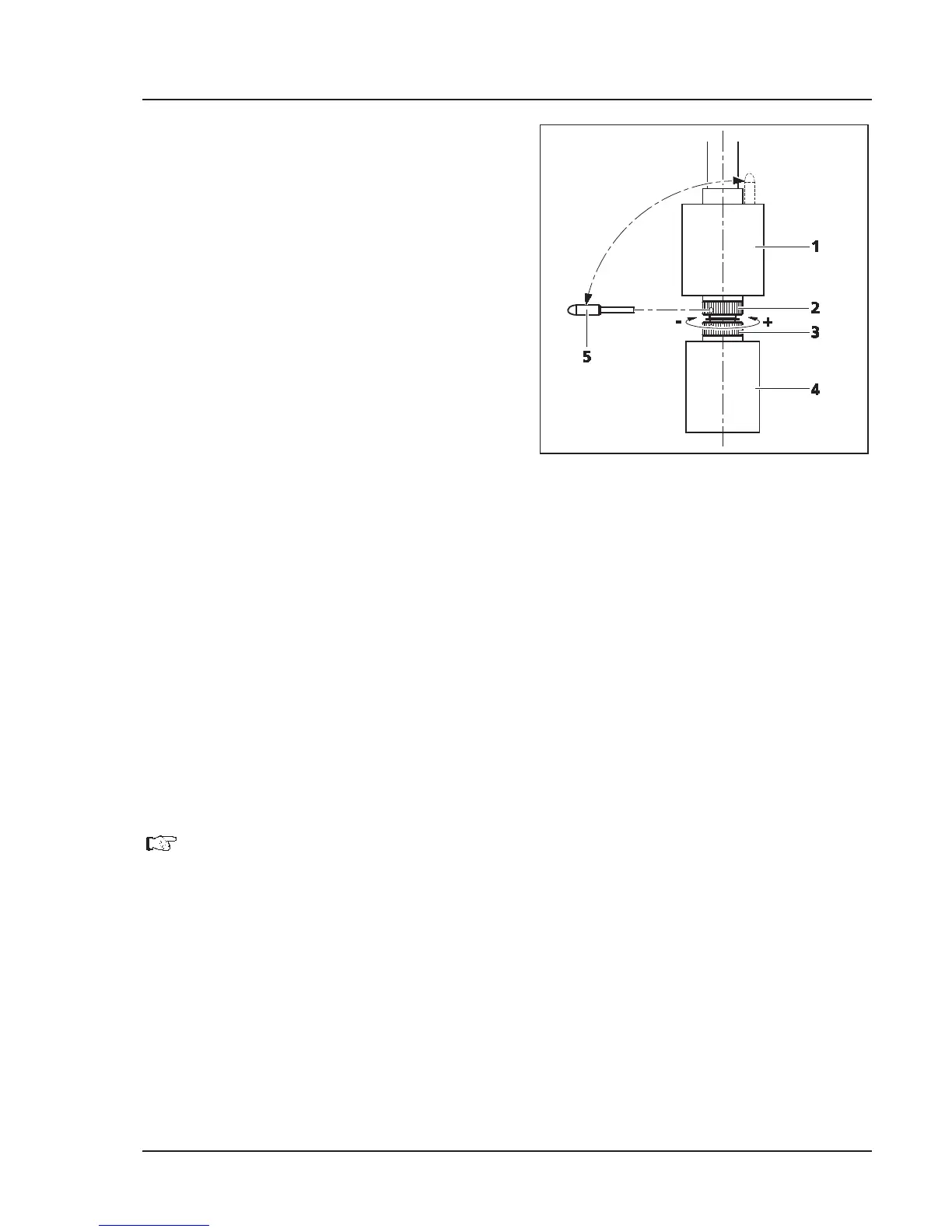

3.1.7.4 Setting friction torque of drive

knobs for X/Y adjustment of the

mechanical stage

(1) X drive

x Push drive knob for X adjustment (Fig. 3-11/4)

right to the bottom.

x Remove supplied adjusting pin (Fig. 3-11/5)

from the drive knob for Y adjustment

(Fig. 3-11/1) and insert into one of the holes of

the lower hole nut(Fig. 3-11/3).

x Hold the drive knob for X adjustment

(Fig. 3-11/4) and turn the hole nut with the

adjusting pin in a clockwise direction (small

friction torque: –) or counter-clockwise (large

friction torque: +) until the desired freedom of

movement has been achieved (see Fig. 3-11).

x It should not be shifted more than one

revolution.

(2) Y drive

x Push drive knob for Y adjustment (Fig. 3-11/1) right to the top.

x Insert the supplied adjusting pin (Fig. 3-11/5) into the hole of the upper hole nut (Fig. 3-11/2).

x Hold the drive knob for Y adjustment (Fig. 3-11/1) and turn the hole nut with the adjusting pin in a

clockwise direction (small friction torque: –) or counter-clockwise (large friction torque: +) until the

desired freedom of movement has been achieved.

x It should not be shifted more than one revolution.

x Re-insert the adjusting pin into the drive knob for Y adjustment (Fig. 3-11/1).

Set the friction torque on the mechanical stage with ergonomic, stationary X-

Y drive

analogously. No tool is required for the purpose. The lock-nut (silver) of the respective drive

can be adjusted manually; hold the drive knob tight.

Fig. 3-11 Setting friction torque

Loading...

Loading...