Section 1

Creating bar codes

Since there is only limited printing space on a slide, the

bar code should not contain more information than is

necessary. An error-checking code should be used, making

it easier for the bar code scanner to recognize possible

errors. Some codes support error correction.

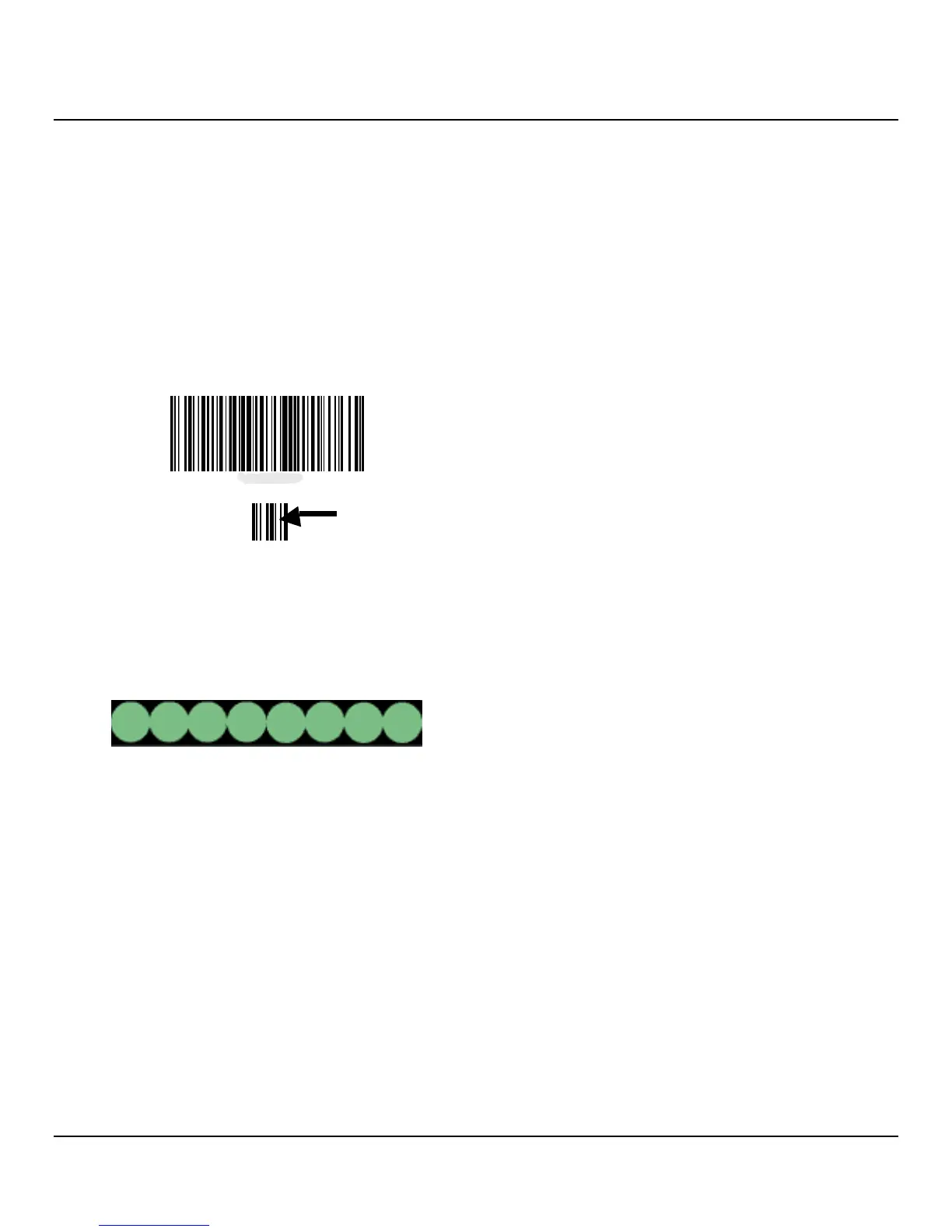

When calculating and creating bar codes, remember

the resolution capabilities of the printer. The module size

is the width of the smallest element of a bar code

(Figure 1-I).

Module/Smallest

element

Printing Surfaces

To obtain reliable results, high-quality slides should be

used. Printable slide areas that only allow for low resolution

may be fine for printing text (depending on font type and

size), but are not suitable for printing bar codes. The printer

resolution should be selected to correspond to the

resolution of the print medium. Even a perfect-looking bar

code can sometimes be difficult to scan due to low

contrast. Depending on the color of light used to illuminate

the bar code symbol a slide color providing a good contrast

should be used.

Bar Code Scanners

In addition to the correct bar code creation and the

quality of the slides, the features of the bar code scanner

used also have an impact on scanning results.

Important features include:

Reading tolerance:

Difference between the actual bar code width

0

and nominal module size

Figure 1-I

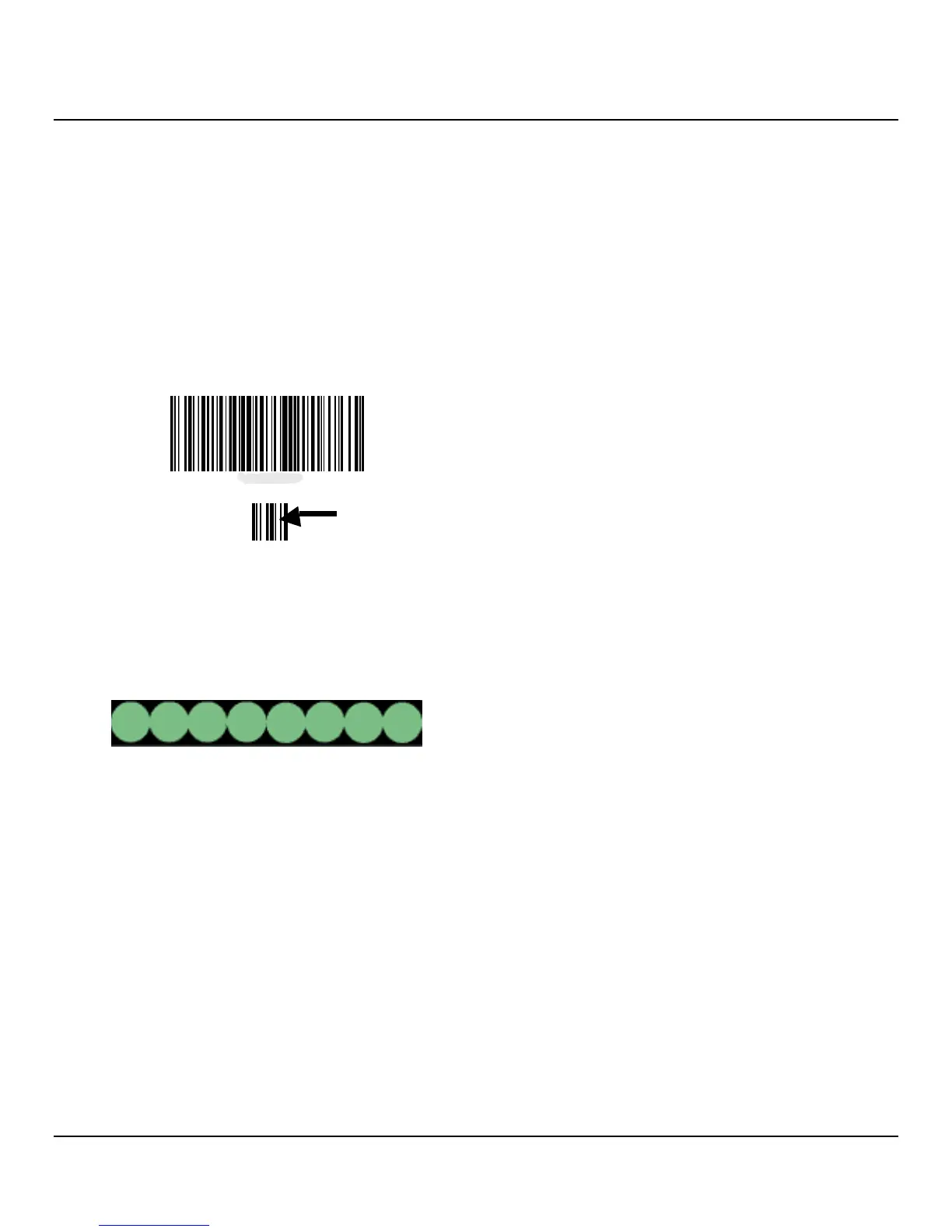

Wider bars and spaces are calculated in multiples of

the module size. The module size is an integral factor of

the printer resolution since only "whole" dots can be

printed (Figure 1-J).

Figure 1-J

A reading error may occur (even if the print appears to

be crisp and correct) if, due to conversion, the module

width and resolution no longer match.

NOTE:

The data should not be printed as a bar code only,

but also as text (line of optical characters above or below

the bar code) to ensure that no information is lost.

Light color:

There should be a high contrast to the color of

0

the slides being used.

Optical resolution:

Must be better than the module size.

0

Depending on the application (program) used to

generate bar code information, the following features

should also be considered:

Maximum readable distance

Resistance against

reagents

The ink's absolute resistance to wiping can not be

guaranteed under all foreseeable laboratory conditions, as

the surface finish of the used slide's print field is decisive

in this regard. Therefore, the print field of the printed slide

should not be touched or wiped while damp.

NOTE:

All slides must be tested before use. Sakura

Finetek assumes no responsibility for any damage due to

prints of poor quality or prints made with non-reagent-

resistant ink.

Loading...

Loading...