EB 8015 EN 8-1

Malfunctions

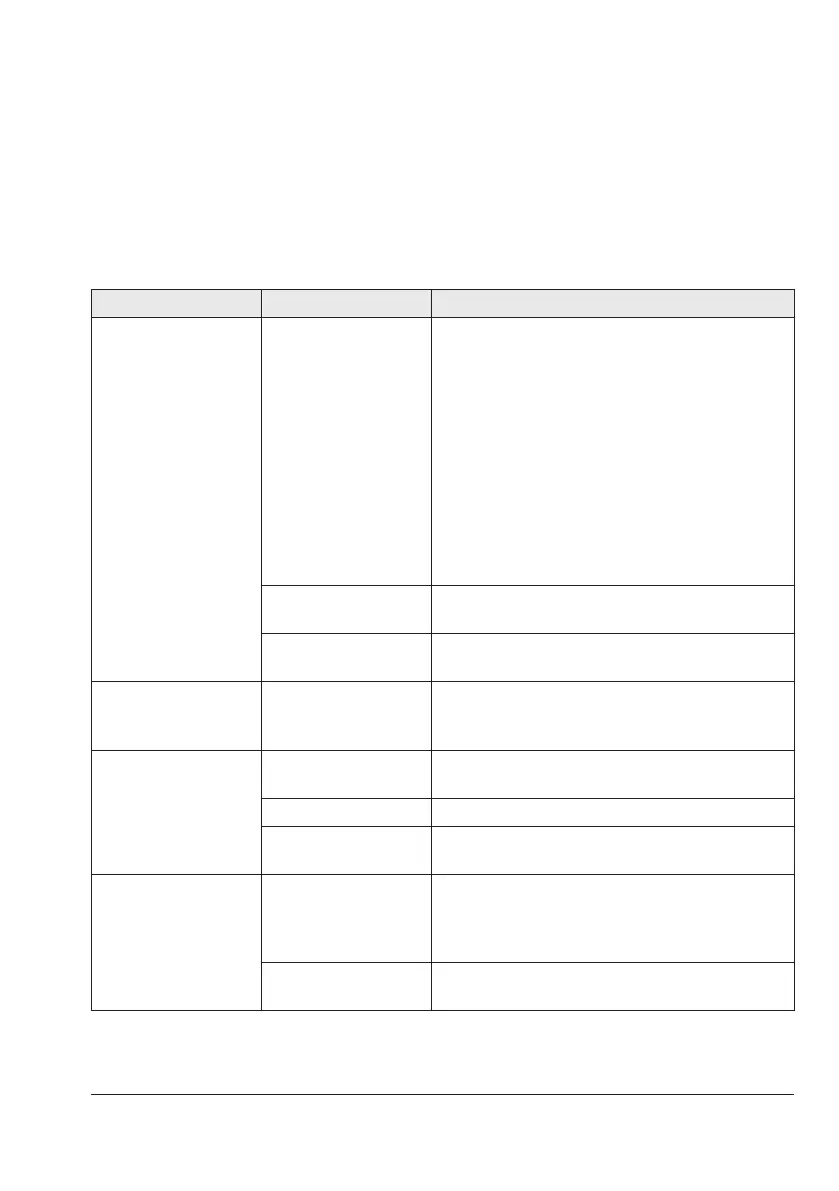

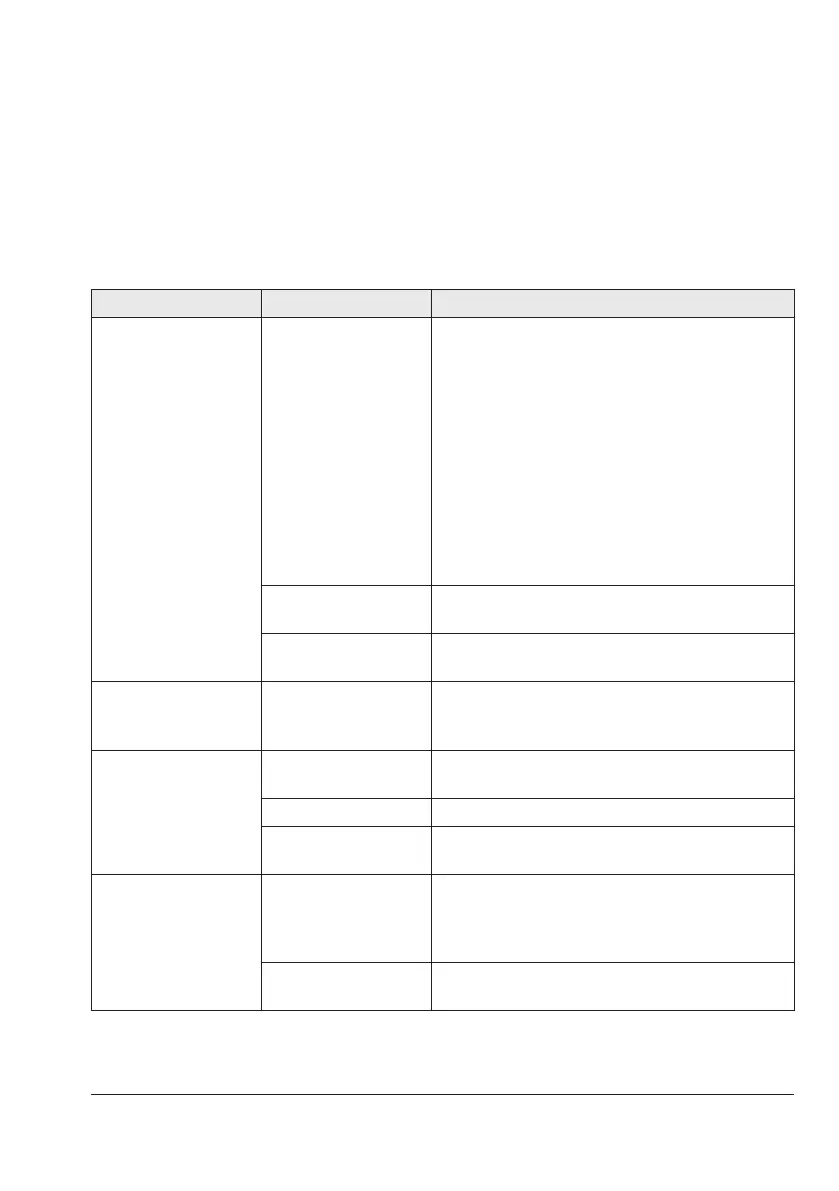

8 Malfunctions

Read hazard statements, warnings and caution notes in the 'Safety instructions and mea-

sures' section.

8.1 Troubleshooting

Malfunction Possible reasons Recommended action

Actuator and plug stem

does not move on

demand.

Actuator is blocked. Check attachment.

Remove the blockage.

WARNING! A blocked actuator or plug stem (e.g.

due to seizing up after remaining in the same

position for a long time) can suddenly start to move

uncontrollably. Injury to hands or ngers is possible

if they are inserted into the actuator or valve.

Before trying to unblock the actuator or plug stem,

disconnect and lock the pneumatic air supply as

well as the control signal. Before unblocking the

actuator, release any stored energy in the actuator

(e.g. spring compression). See associated actuator

documentation.

Diaphragm in the actu-

ator defective

See associated actuator documentation.

Signal pressure too low Check the signal pressure.

Check the signal pressure line for leakage.

Jolting movement of the

actuator and plug stem

Packing tightened too

far

Tighten the packing correctly (see information under

'Adjusting the packing' in the 'Testing the installed

valve' section).

Actuator and plug stem

does not stroke through

the entire range.

Signal pressure too low Check the signal pressure.

Check the signal pressure line for leakage.

Travel stop active See associated actuator documentation.

Incorrect setting of

valve accessories

Check the settings of the valve accessories.

Increased ow through

closed valve (seat leak-

age)

Dirt or other foreign

particles deposited be-

tween the seat and

plug.

Shut off the section of the pipeline and ush the

valve.

Valve trim, particularly

with soft seat, is worn.

Replace seat and plug (see the 'Servicing' section)

or contact our after-sales service.

Loading...

Loading...