EB 8039 EN 3-1

Design and principle of operation

3 Design and principle of oper-

ation

Fail-safe action

IntheType3351Valve,theconnectedpneu-

matic control pressure (5.8) opposes the

force of the spring (5.5) to open or close the

valve.

Depending on the design of the valve seat

(2) and where the plug (3) is located inside

the valve, the valve has two different fail-safe

actions which become effective when the

pressure is relieved from the diaphragm

(5.4) or the supply of control pressure fails.

− Fail-closevalve: upon failure of the con-

trol pressure, the valve is closed by the

spring.

− Fail-openvalve: upon failure of the con-

trol pressure, the valve is opened by the

spring.

For versions with the optional handwheel (6),

a fail-close valve can be opened and a fail-

open valve can be closed in the event of con-

trol pressure failure.

Directionofow(seeTable3-1)

Thedirectionofthemediumowinthevalve

depends on the process medium and the se-

lected fail-safe action.

For fail-close valves which are used to con-

trolgasesandvapors,themediummustow

intheow-to-closedirection(AB).

ExceptfortheDN100version: the medium

mustowintheow-to-opendirection

(BA).

For control applications with liquids, the me-

diummustowintheow-to-opendirection

(BA).

Infail-openvalves,allmediamustowin

theow-to-opendirection(A B).

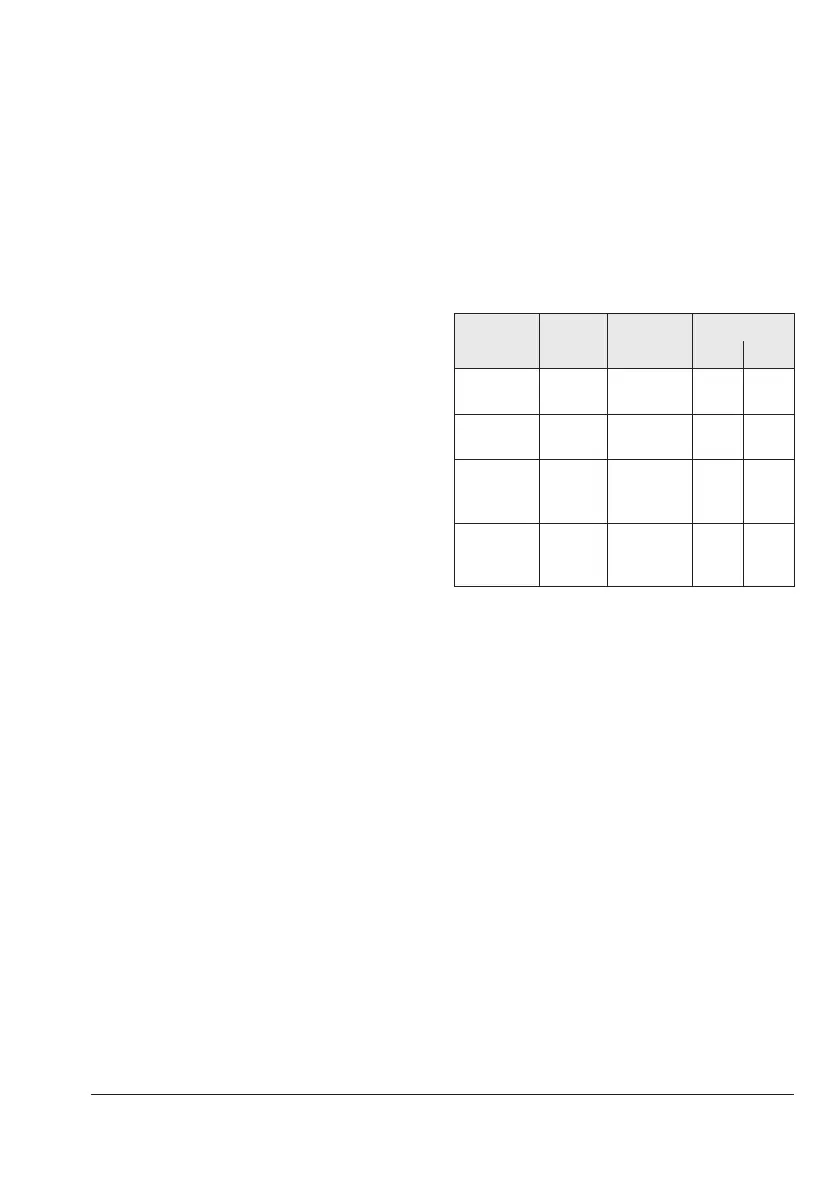

Table3-1: Direction of ow

Fail-safe ac-

tion

Process

medium Valve size

Flow direction

AB BA

Fail-close Vapor/gas

DN15to80

NPS½to3

FTC

1)

–

Fail-close Vapor/gas

DN100

NPS4

– FTO

1)

Fail-close Liquid

DN15to

100

NPS½to4

– FTO

1)

Fail-open

Vapor/

gas/liquid

DN15to

100

NPS½to4

FTO

1)

–

1)

FTO(ow-to-open)

FTC(ow-to-close)

Control pressure and max. differential

pressureΔp

Table 3-5 shows the correlation between

control pressure and max. differential pres-

sureΔpbasedontheprocessmediumused.

Loading...

Loading...