9-6 EB 8039 EN

Servicing

9.4.1 Disassembly(DN15to

80/NPS½to3)

1. Remove nuts and bolts at the actuator.

For versions with handwheel, turn the

handwheel to ensure that the spring plate

(5.6) is not under tension. Remove the di-

aphragm case (5.7) and take out the di-

aphragm.

2. Placeshim(around5mmthick)onthe

springplate(seeFig.9-2).Placeon

mounting device and fasten with three

clamping bolts and nuts. Turn the nuts

until the spring plate (5.6) is evenly load-

ed slightly. This causes the plug (3) to de-

tach itself from the seat.

3. Completelyundothethreadedbushing

(5.2). Spray the lock nut (3.2) stuck with

adhesive to the plug stem as well as the

ends of the plug stem with solvent. Use a

hot-air gun to soften the adhesive and

undo the lock nut (3.2). Position plug

wrench (see the 'Tightening torques, lu-

bricants and tools' section in the annex)

orhexscrewdriver(DN65/80)and

carefully turn the plug stem clockwise un-

til its height has changed by approx.

6mm.

4. Unthread the clamping bolts of the

mounting device and the plug stem grad-

ually until the plug stem is unscrewed out

of the spring plate (5.6). Remove spring

plate and spring. Unscrew lock nut (3.2).

5. Remove valve bonnet (5) from valve

body and carefully pull it up, for fail-

close version over the plug stem and for

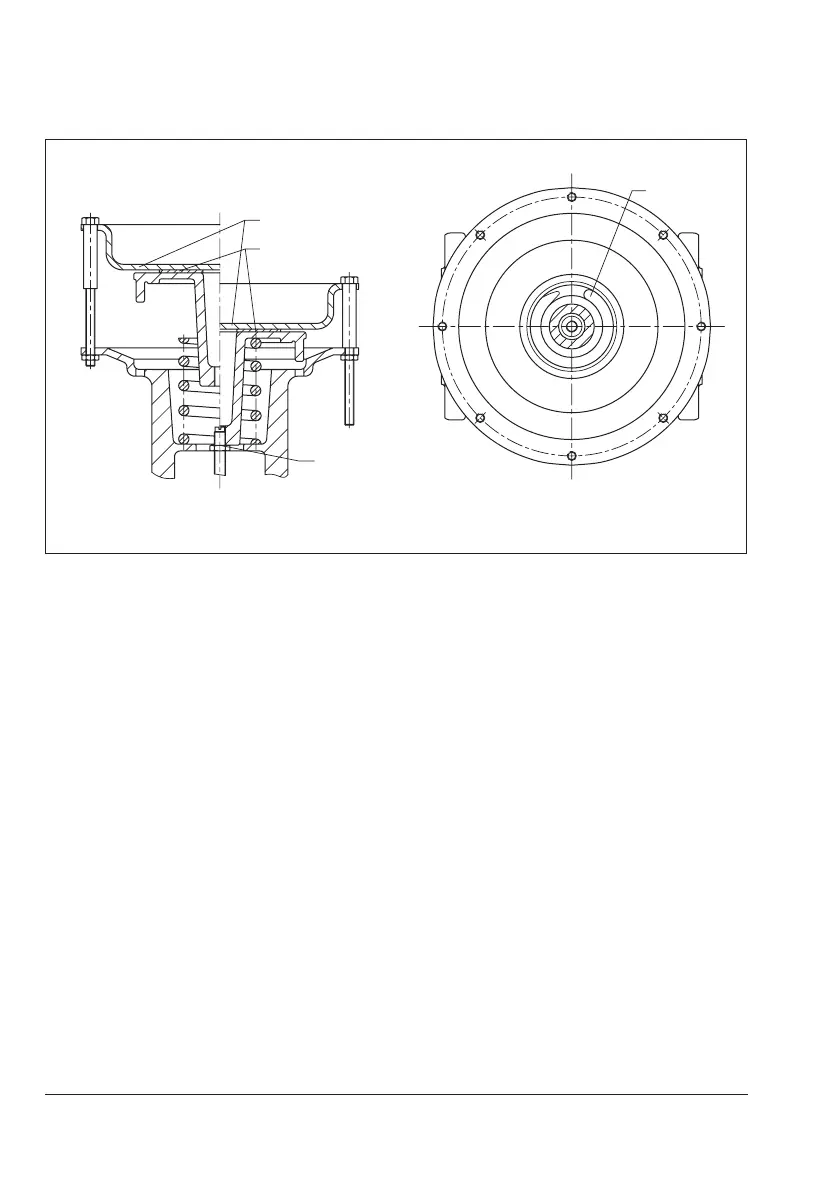

Mounting device

Washer

Spacer used for

disassembly

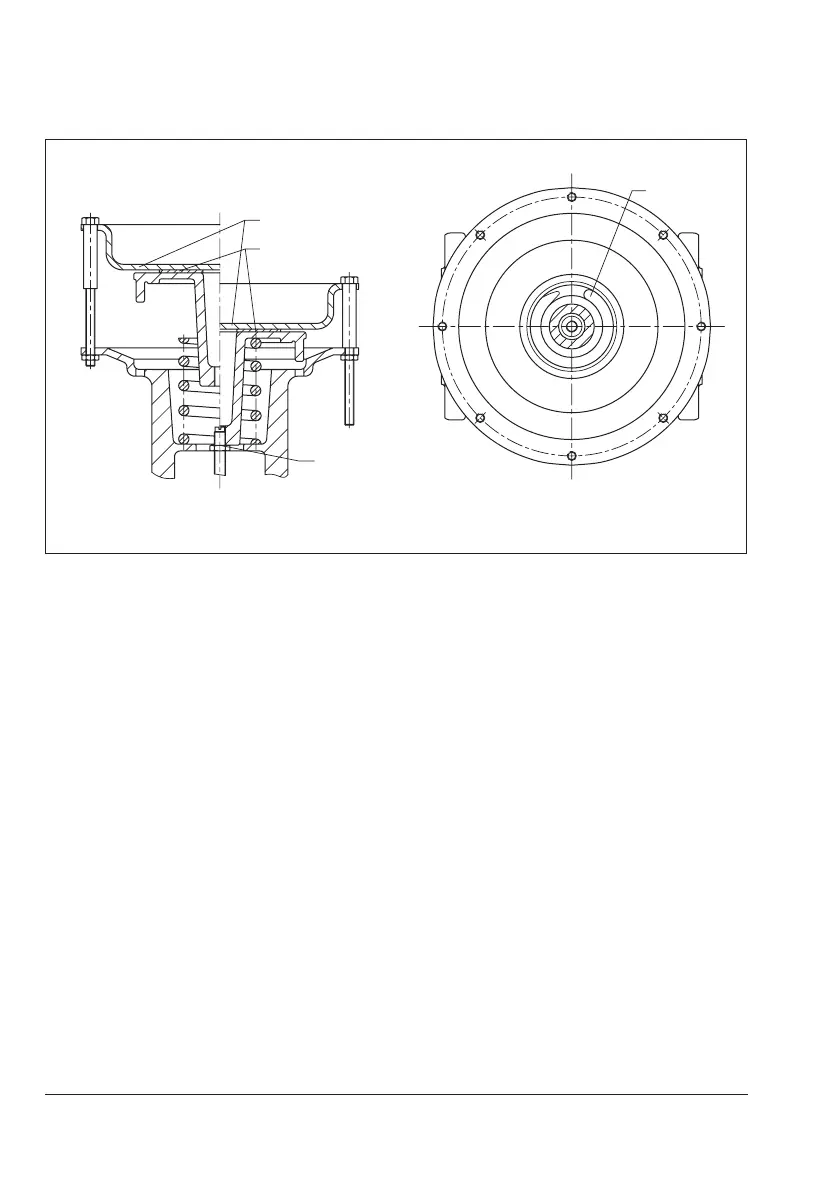

Spring

Fig.9-2: Mounting device (DN15 to 80) Fig.9-3: Alignment of the spring

Loading...

Loading...