EB 8039 EN 9-3

Servicing

9.1 Periodic testing

Depending on the operating conditions,

check the valve at certain intervals to prevent

possible failure before it can occur. Plant op-

erators are responsible for drawing up an

inspection and test plan.

Our after-sales service can support you in

drawing up an inspection and test plan for

your plant.

Tip

We recommend the following inspection and testing which can be performed while the pro-

cess is running:

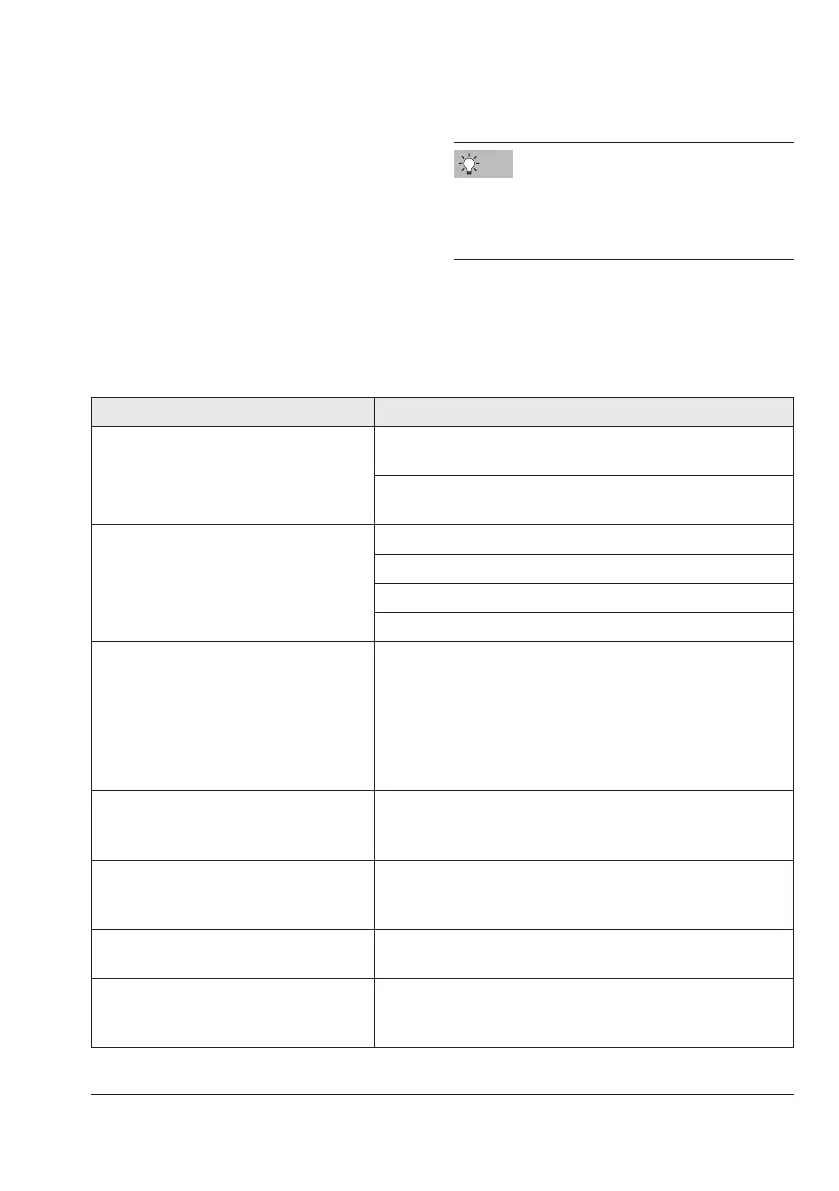

Inspection and testing Actiontobetakenintheeventofanegativeresult:

Checkthemarkings,labelsand

nameplates on the valve for their

readability and completeness.

Immediately renew damaged, missing or incorrect

nameplates or labels.

Cleananyinscriptionsthatarecoveredwithdirtandare

illegible.

Checkthepipeconnectionsandgaskets

on the valve and actuator for leakage.

Checktheboltedjoint(tighteningtorque).

Replacethegasketontheangedjoint.

Replacethediaphragm(seesection9.4).

Replacethepacking(seesection9.4)

Checkthetestconnectionforexternal

leakage.

WARNING! Risk of personal injury due

topressurizedcomponentsandprocess

medium being discharged. Do not

loosen the screw of the test connection

whilethevalveispressurized.

Put the control valve out of operation (see the

'Decommissioning' section).

Checkthevalve'sseatleakage. Shutoffthesectionofthepipelineandushthevalveto

remove any dirt and/or deposited foreign particles between

the seat and plug.

Checkthevalveforexternaldamage

(e.g. corrosion).

Repair any damage immediately. If necessary, put the

control valve out of operation (see the 'Decommissioning'

section).

Checkthevalveaccessoriestoensure

they are mounted properly.

Tighten the connections of the valve accessories.

If possible, check the valve's fail-safe

positionbybrieyinterruptingtheair

supply.

Put the control valve out of operation (see the

'Decommissioning' section). Identify the cause for the

malfunction and rectify it (see the 'Troubleshooting' section).

Loading...

Loading...