5-4 EB 8039 EN

Installation

5.3.1 Mounting the actuator

onto the valve

Risk of personal injury due to preloaded

springs.

The valve is tted with an actuator with pre-

loaded springs that are under tension.

Î Before starting any work on the control

valve, relieve the compression from the

preloaded springs. See 'Relieving the

spring compression in the actuator' in the

'Removal' section.

TheType3351ControlValveisdeliveredby

SAMSON with the actuator ready mounted

on the valve.

5.3.2 Installing the valve into

the pipeline

Premature wear and leakage due to insuf-

cient support or suspension.

Î Support or suspend the valve sufciently

at suitable points.

Directionofow

Thedirectionofthemediumowinthevalve

depends on the process medium and the se-

lected fail-safe action:

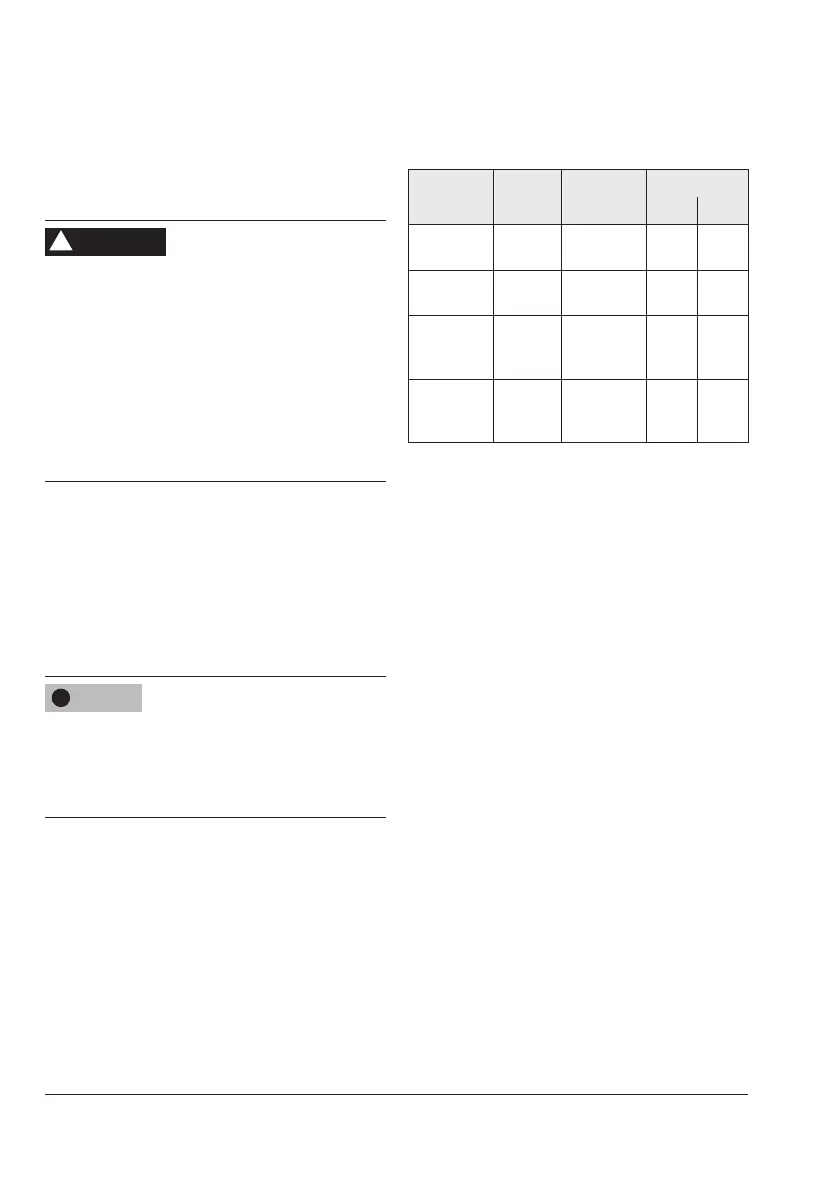

Table5-2: Direction of ow

Fail-safe

action

Process

medium Valve size

Flow direction

AB BA

Fail-close Vapor/gas

DN15to80

NPS½to3

FTC

1)

–

Fail-close Vapor/gas

DN100

NPS4

– FTO

1)

Fail-close Liquid

DN15to

100

NPS½to4

– FTO

1)

Fail-open

Vapor/

gas/liquid

DN15to

100

NPS½to4

FTO

1)

–

1)

FTO(ow-to-open)

FTC(ow-to-close)

Installing the control valve

1. Closetheshut-offvalvesinthepipeline

at the inlet and outlet of the plant section

while the valve is being installed.

2. Prepare the relevant section of the pipe-

line for installing the valve.

3. Remove the protective caps from the

valve ports before installing the valve.

4. Lift the valve using suitable lifting equip-

ment to the site of installation (see infor-

mation under 'Lifting the valve' in the

'Shipment and on-site transport' section).

Observetheowdirectionthroughthe

valve(seeprecedingparagraph“Direc-

tionofow”).

5. Makesurethatthecorrectangegaskets

are used.

6. Bolt the pipe to the valve free of stress.

7. Attach a support or suspension on the

valve, if necessary.

WARNING

!

NOTICE

!

Loading...

Loading...