EB 8039 EN 15-1

Annex

15 Annex

15.1 Tightening torques, lubricants and tools

Tightening torques

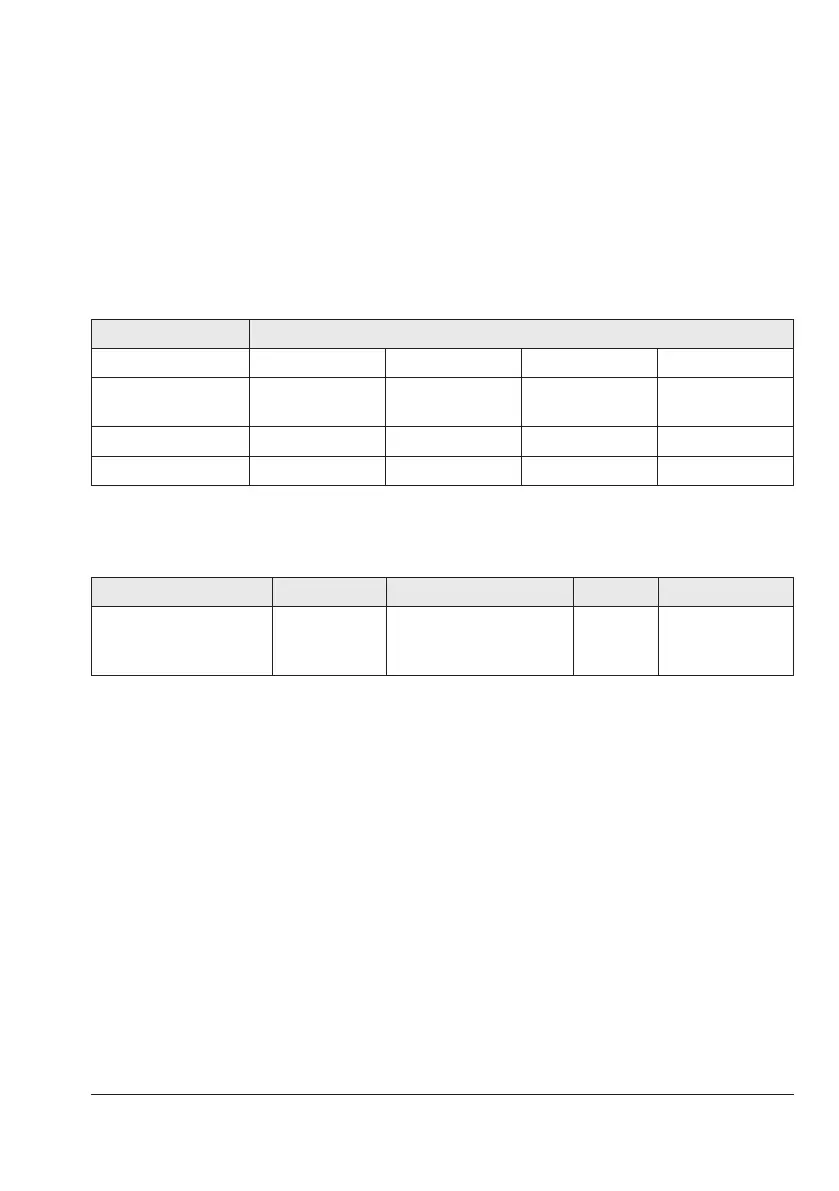

Table15-1: Tightening torques

Part Tightening torques

Nuts (1.1) M10/20Nm M12/35Nm M16/90Nm M20/170Nm

Packing (5.2)

M20x1.5/

20Nm

M20x1.5/

80Nm

M26x1.5/

110Nm

M26x1.5/

110N

Nuts (5.9) M6/13Nm M8/18Nm M8/18Nm M8/18Nm

Seat (2) 150Nm 400Nm 850Nm 1050Nm

Lubricants

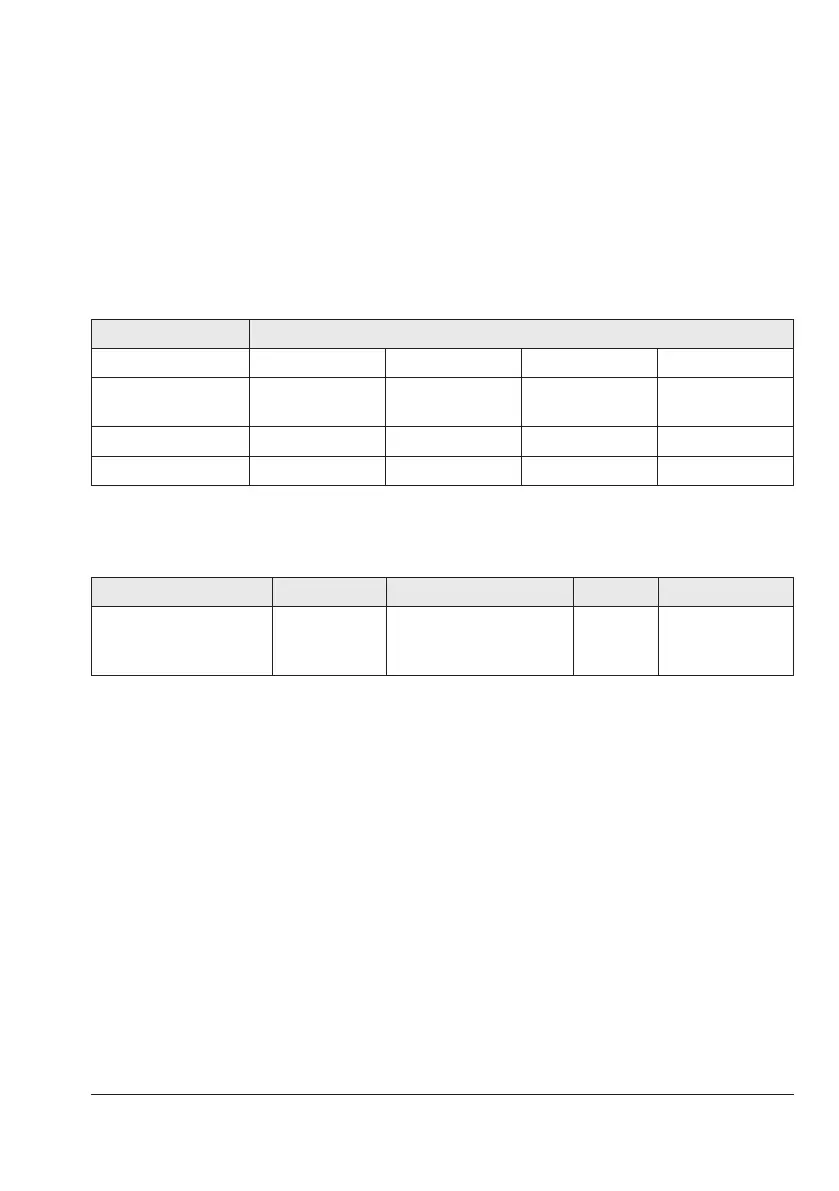

Table15-2: Recommended lubricant

Application Trade name Temperature range in °C Color Material no.

Chemical-resistant,

high-temperature

grease

1)

Gleitmo

®

591 –25 to +260 White 8150-0111

1)

Componentsthataretobelubricatedandtoolsusedforlubricationmustbefreeofoilandgrease.

Tools

In addition to the standard tool, special tools are required to assemble and remove some

parts (see Table 15-3). Use adjustable torque wrenches with a stop signal or that indicate the

torquebeingappliedtoachievetherighttighteningtorques.Valvesinlargevalvesizesoften

require tightening torques that can only be achieved through additional torque multiplication

by using a torque multiplier or hydraulic power tool. The required special tools can be pur-

chased from SAMSON.

Î ContactAfter-salesservice.

Loading...

Loading...