1. Make sure that you have all the required tools (pipe cutter, reamer, aring tool and pipe holder).

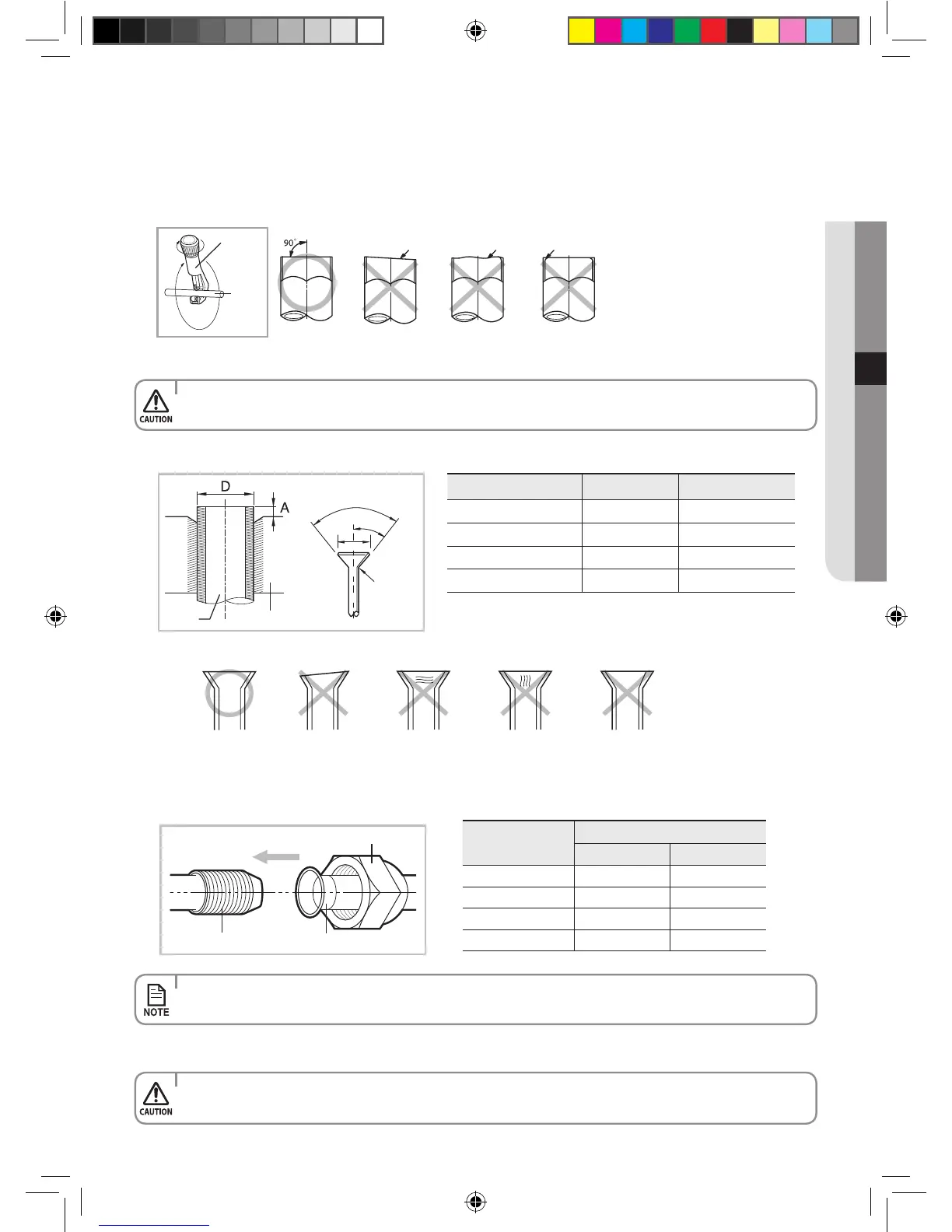

2. If you want to shorten the pipe, cut it using a pipe cutter, ensuring that the cut edge remains at 90° with the side of the

pipe (see below examples of correct and incorrect cut edges).

Oblique Rough Burr

Pipe

cutter

Pipe

3. To prevent a gas leak, remove all burrs at the cut edge of the pipe using a reamer.

• Facethepipedownwhileremovingtheburrstomakesurethatburrsdonotgetintothepipe.

Indoor outlet pipe Connecting pipe

Flare nut

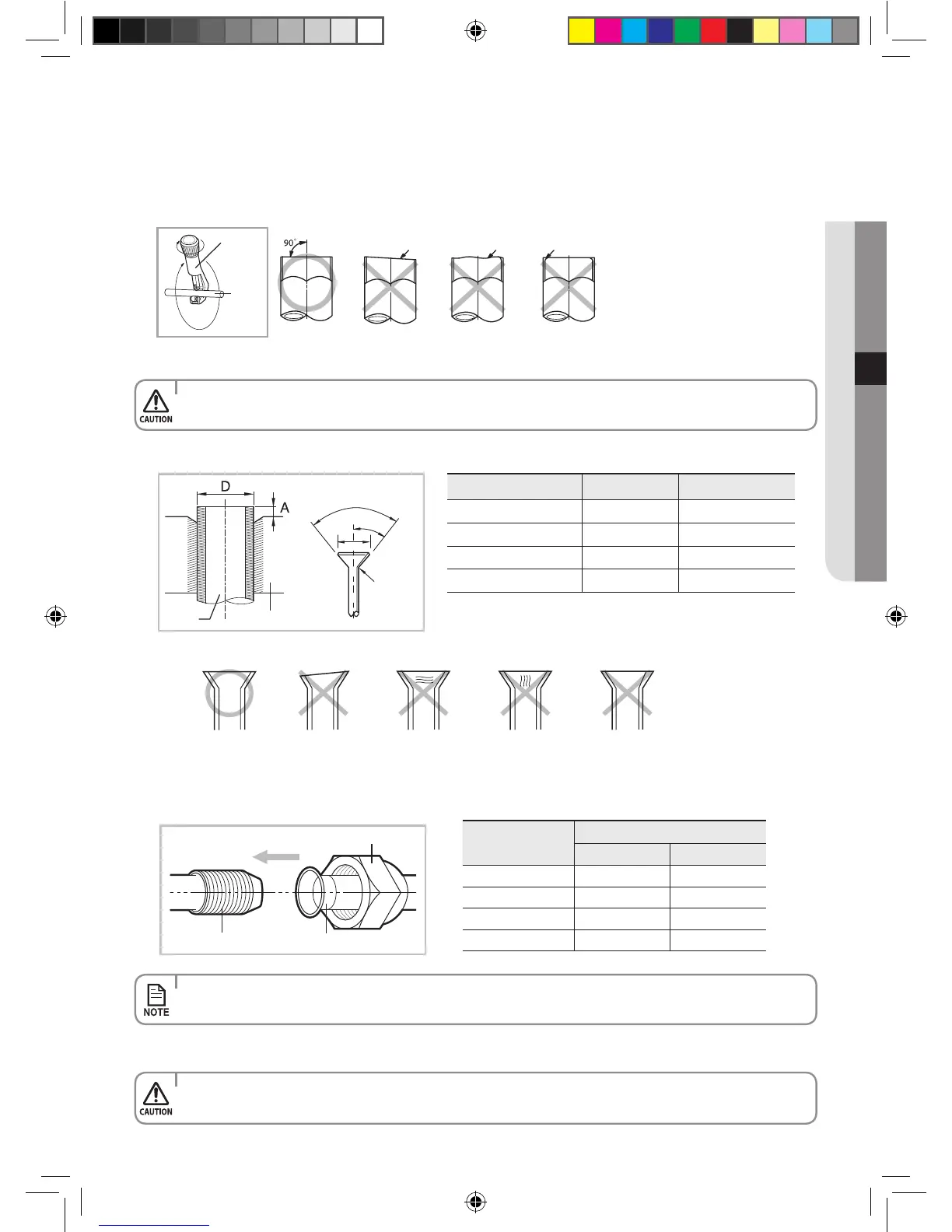

5. Check if you ared the pipe correctly (see examples of incorrectly ared pipes below).

6. Align the pipes to connect them easily. Tighten the are nuts rst with your hands, and then with a torque wrench,

applying the following torque:

7. For further details on how to connect to the outdoor unit and evacuate the air, refer to page 44~46.

Correct

Uneven

Thickness

Cracked

Damaged

Surface

Inclined

• Excessivetorquecanbecauseofgasleakage.Ifextendingpipebywelding/brazingpleaseensurenitrogenisused

during welding/brazing process. The joint must be accessible and serviceable.

• Tightenthearenutwithtorquewrenchaccordingtospeciedmethod.

If the are nut is over-tightened, the are may break and cause refrigerant gas leakage.

4. Put a are nut slightly into the pipe and modify the are.

Outer Diameter (D) Depth (A) Flaring Size (B)

ø6.35 mm 1.3 mm 8.7 - 9.1 mm

ø9.52 mm 1.8 mm 12.8 - 13.2 mm

ø12.70 mm 2.0 mm 16.2 - 16.6 mm

ø15.88 mm 2.2 mm 19.3 - 19.7 mm

Pipe Flare

90°± 2°

°

2

±°

5

4

R 0.4~0.8

B

Outer Diameter

Torque

N•m kgf•cm

ø6.35 mm 14~18 140~180

ø9.52 mm 34~42 350~430

ø12.70 mm 49~61 500~620

ø15.88 mm 68~82 690~830

English-41

INSTALLATION05

A3050 CB&XL&CH_IB&IM_DB68-04138A_HP&CO_EN.indd 41 2013-12-28 14:43:47

Loading...

Loading...