s05mdl1sm-REV0708

SERVICE & OPERATING MANUAL

WARREN RUPP, INC. • A Unit of IDEX Corporation • P.O. Box 1568, Mansfi eld, Ohio 44901-1568 USA • Telephone (419) 524-8388 • Fax (419) 522-7867 • www.warrenrupp.com

©Copyright 2008 Warren Rupp, Inc. All rights reserved.

Table of Contents

U.S. Patent #

5,996,627 & 6,241,487

Other U.S. Patents

Applied for

Engineering Data and Temperature Limitations ........................................................1

Explanation of Pump Nomenclature .........................................................................2

Performance Curve...................................................................................................3

Dimensions (Aluminum Model) .................................................................................4

Metric Dimensions (Aluminum Model) ......................................................................5

Dimensions (Stainless Steel and Alloy C Models) ....................................................6

Metric Dimensions ( Stainless Steel and Alloy C Models) ........................................7

Principle of Pump Operation .....................................................................................8

Installation and Start-up ...........................................................................................8

Air Supply .................................................................................................................8

Air Valve Lubrication .................................................................................................8

Air Line Moisture .......................................................................................................8

Air Inlet and Priming .................................................................................................8

Between Uses ..........................................................................................................8

Installation Guide ......................................................................................................9

Troubleshooting .....................................................................................................10

Warranty .................................................................................................................10

Recycling ................................................................................................................11

Important Safety Information ..................................................................................11

Material Codes .......................................................................................................12

Composite Repair Parts Drawing ...........................................................................14

Available Service and Conversion Kits ...................................................................14

Composite Repair Parts List ...................................................................................15

Air Distribution Valve Assembly Drawing and Parts List .........................................16

Air Distribution Valve Servicing ...............................................................................17

Air Valve with Stroke Indicator Assembly Drawing and Part List ............................18

Air Distribution Valve with Stroke Indicator Option Servicing ..................................19

Solenoid Shifted Air Valve Drawing and Parts List .................................................20

Solenoid Shifted Air Distribution Valve Option ........................................................21

Diaphragm Service Drawing, Non-Overlay .............................................................22

Diaphragm Service Drawing, with Overlay .............................................................22

Diaphragm Service Drawing ..................................................................................22

Diaphragm Servicing ..............................................................................................23

Overlay Diaphragm Servicing ................................................................................23

Pilot Valve Servicing, Assembly Drawing & Parts List ............................................24

Intermediate Assembly Drawing and Parts List ......................................................25

Intermediate Assembly and Actuator Plunger Servicing ........................................25

Check Valve Servicing ............................................................................................26

Check Valve Drawing ..............................................................................................26

Optional Muffl er Confi guration Drawing ..................................................................27

Dual Port Option Drawing (Aluminum Model) .........................................................28

Dual Porting Options (Aluminum Model) ................................................................29

Dual Porting Suction and Discharge (Aluminum Model) ........................................29

Single Porting Suction and Dual Porting Discharge (Aluminum Model) .................30

Dual Porting Suction and Single Porting Discharge (Aluminum Model) .................30

Single Port Suction and Discharge Repair Parts List (Aluminum Model) ...............30

Dual Port Suction and Discharge Repair Parts List (Aluminum Model) ..................30

Pumping Hazardous Liquids ...................................................................................31

Converting the Pump For Piping the Exhaust Air ...................................................31

Exhaust Conversion Drawing .................................................................................31

Converted Exhaust Illustration ................................................................................31

Pulse Output Kit Drawing .......................................................................................32

Pulse Output Kit Option ..........................................................................................32

Grounding the Pump ..............................................................................................33

CE Declaration of Conformity .................................................................................34

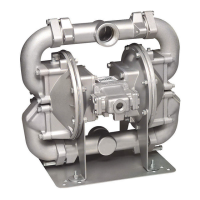

Model S05 Metallic Design Level 1

CE