1997-11:2 © Scania Industrial & Marine Engines 21

c)

Checking protection against corrosion

There must always be sufficient anti-corrosive (inhibitor) in the coolant to

protect the cooling system against corrosion.

If there is no danger of freezing use only Scania Anti-corrosive.

The inhibitor in Scania Anti-corrosive is nitrite-free.

The correct level of anti-corrosive is 7-12% by volume.

- Fill with Scania Anti-corrosive as indicated on the packaging.

- Topping up with 1.0% by volume of Scania Anti-corrosive should be

done after every 2,400 operating hours.

- Never top up with water only or anti-corrosive only. Lost fluid should

always be replaced with pre-mixed coolant:

water + 10% Scania Anti-corrosive by volume.

Note! The coolant should be changed when the cooling system is

cleaned: every 4,800 hours or at least every 5th year.

Changing coolant

1. Remove the filler cap from the expansion tank.

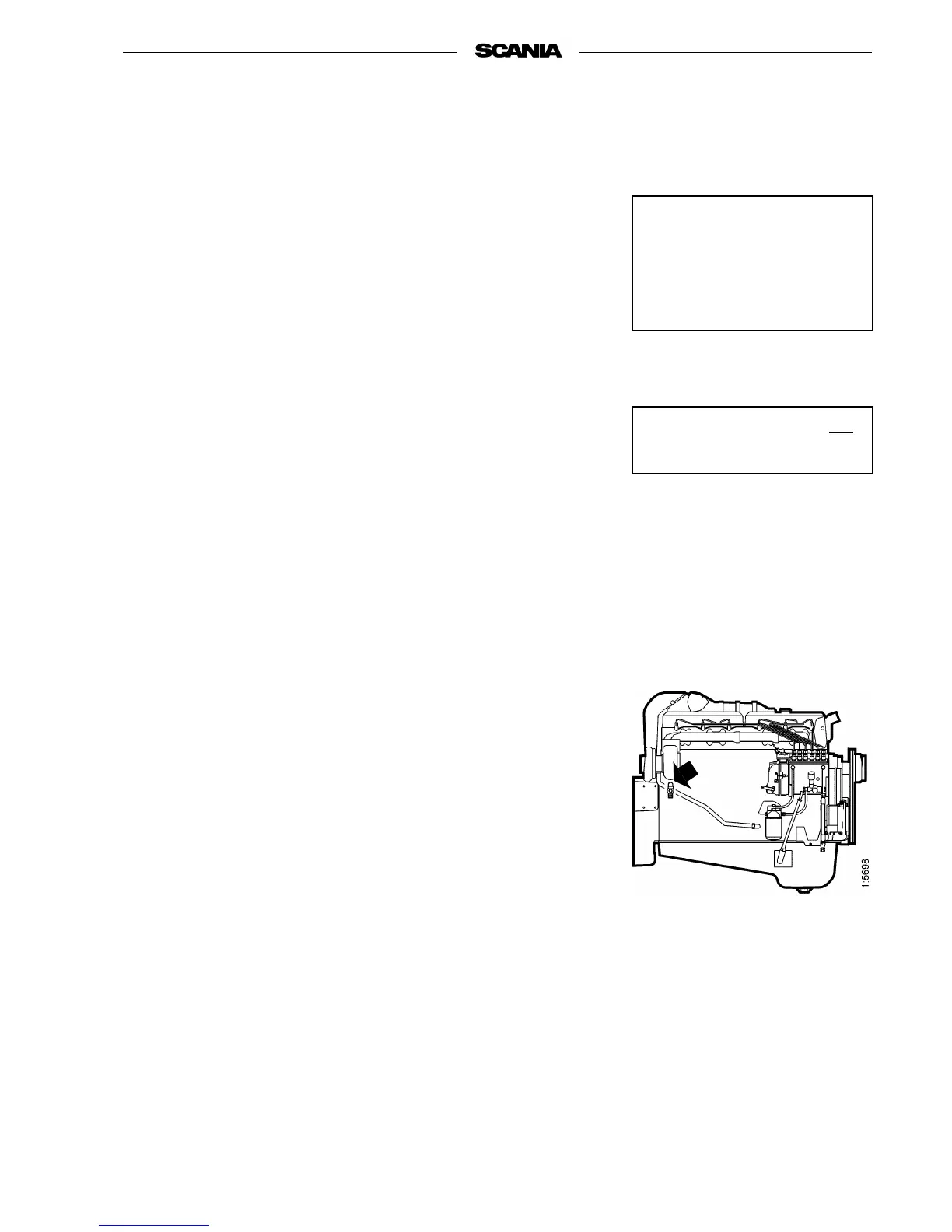

2. The coolant is drained at two points:

-the ”lowest point” of the engine block, see drawing

-the ”lowest point” of the cooling system.

3. Close the valves.

4. Fill coolant through the expansion tank filler hole.

Mix coolant as described on page 19.

Scania Anti-corrosive must not

be mixed with glycol.

Mixing or over concentration

can cause sludging and

reduced cooling capacity.

Any coolant filter must not

contain inhibitor.

Loading...

Loading...