02.00|0889073_ROTA TB-TBS-

39

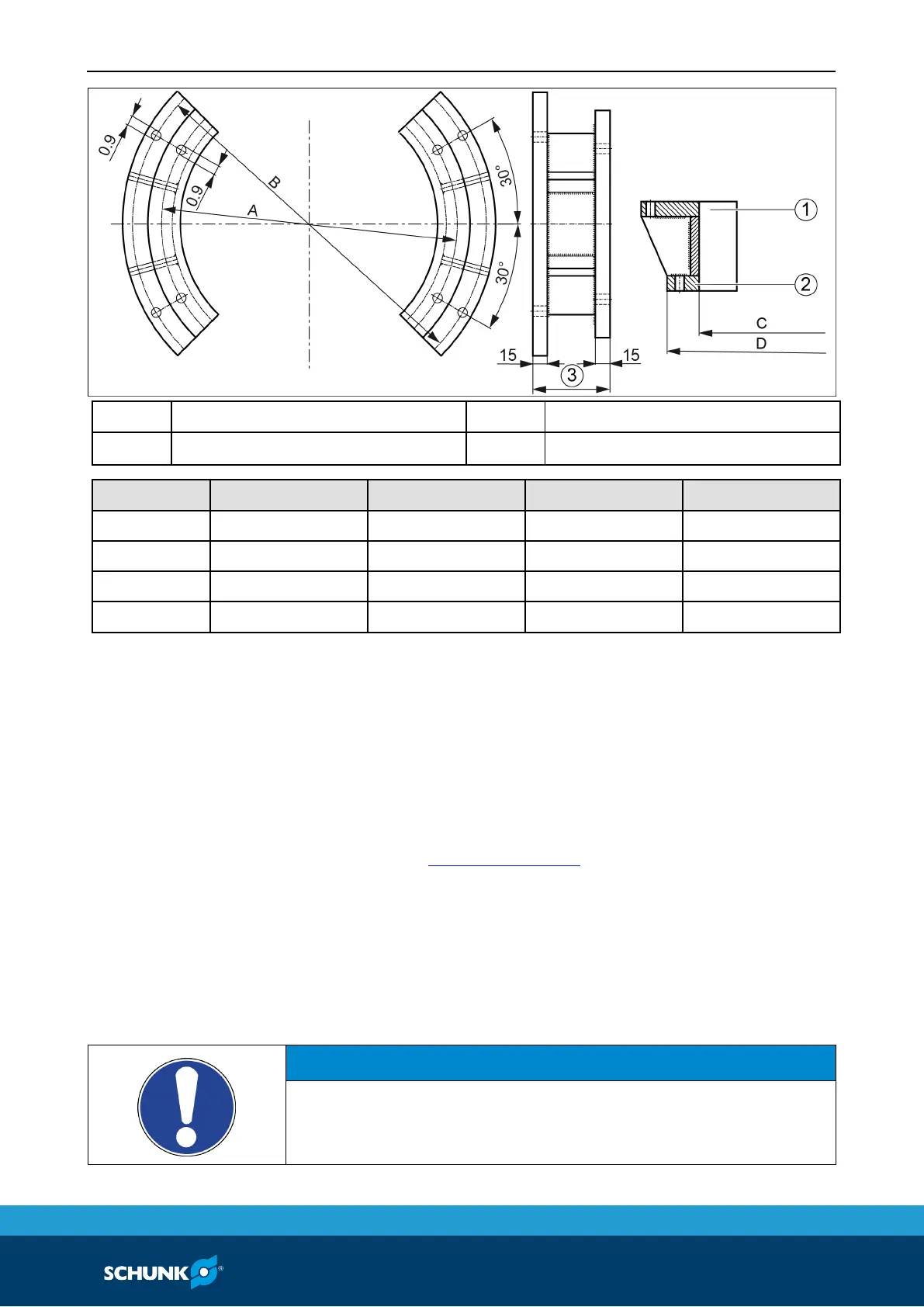

Headstock mounting surface

Distributor ring mounting surface

* Example only (deviations possible)

Mounting with 2-part clamping ring (D.R.M.B.)

The distributor ring can be clamped onto a rigid collar on the

machine (at least 8 mm wide) using a two-piece clamping ring. The

distributor ring is clamped onto this collar using two screws. The

height of the clamping ring is configured as described in the

previous chapter ( 7.2.1, Page 37)

.

During assembly, this two-piece clamping ring is first screwed to

the threads of the distributor ring. Once this is done, the entire

assembly group is clamped onto the rigid collar of the machine.

When mounting the chuck with a bayonet or Camlock, the

clamping ring should have a cut-out to allow access to the collar

nuts or clamping cams using the corresponding wrench.

The distributor ring must be aligned with the outer chuck

diameter in such a way that a radial and axial run-out tolerance

of at least 0.1 mm is achieved.

Loading...

Loading...