MX-5001N SIMULATION 6 – 97

A. (RRC-A) Timing from starting document scanning to specifying

the image lead edge reference is adjusted. (01.mm/step)

* When the value is decreased, the timing is advanced. When

the value is increased, the timing is delayed.

B - F. (RRC-B) Timing of paper (resist roller ON) for the image posi-

tion on the transfer belt is adjusted. (0.1mm/step)

* When the value is decreased, the timing is delayed. When the

value is increased, the timing is advanced.

G. (LEAD) The lead edge image loss amount is adjusted. (0.1mm/

step)

* When the value is increased, the image loss is increased.

H. (SIDE) The side image loss amount is adjusted.

* When the value is increased, the image loss is increased.

(0.1mm/step)

I. (DEN-A) The paper lead edge void amount is adjusted. (0.1mm/

step)

* When the value is increased, the void is increased.

J. (DEN-B) The paper rear edge void amount is adjusted. (0.1mm/

step)

* When the value is increased, the void is increased.

K. (FRONT/REAR) The void amount on the right and left edges of

paper is adjusted. (0.1mm/step)

50-2

Purpose

Adjustment

Function (Purpose)

Used to adjust the copy image position and

the image loss. (This simulation is a simpli-

fied version of SIM 50-1).

Section

Operation/Procedure

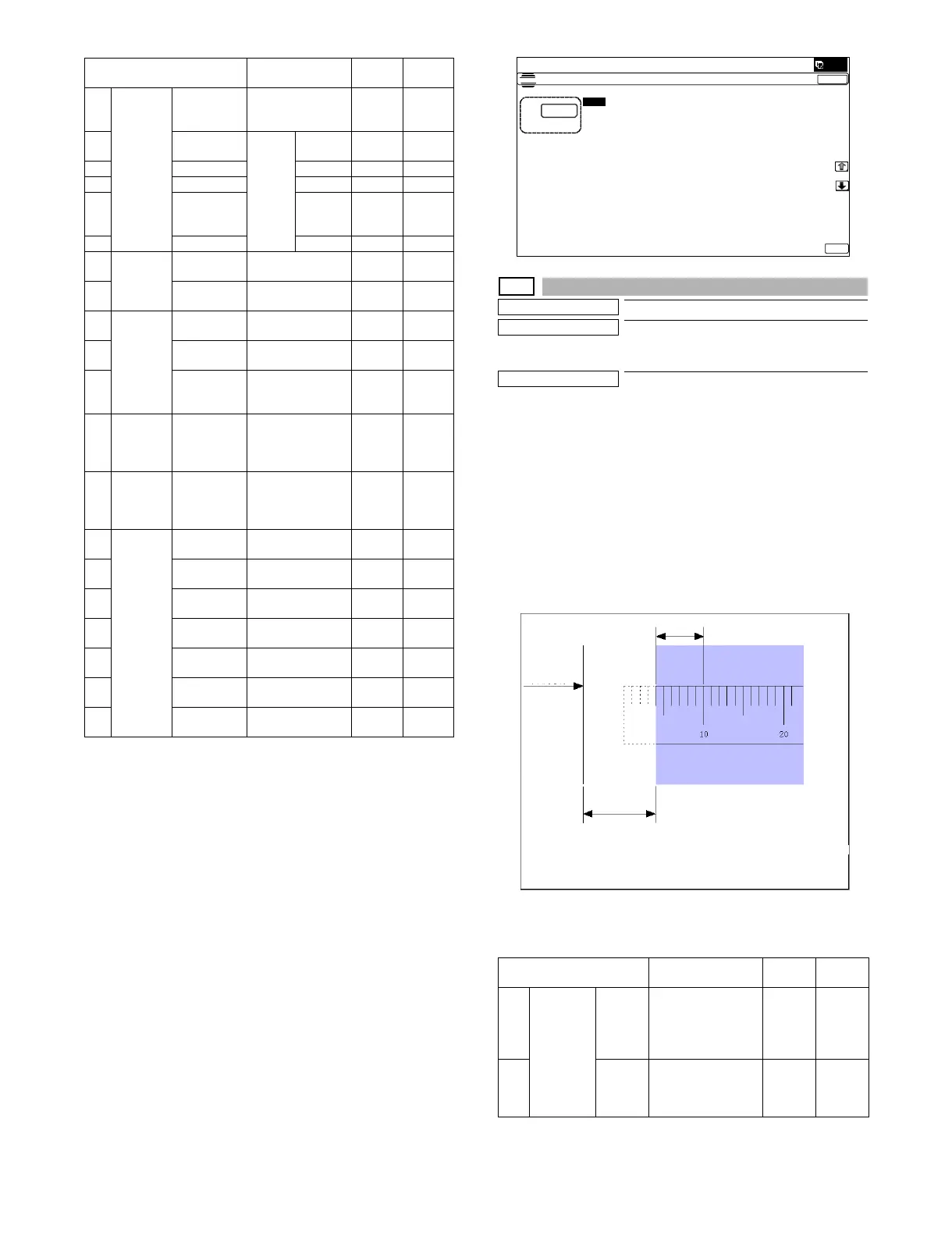

1) Set item A (L1) and item B (L2) to 0.

2) Place a rule on the left edge of the document table, and make

a copy at a magnification ratio of 400%.

3) Measure the length of L1 and L2 on the copied image in the

unit of 0.1mm (referring to the figure below). Enter the adjust-

ment values of L1 x 10 and L2 x 10. Be sure to enter the both

adjustment values of L1 and L2.

L1: Distance from the lead edge of the copied image to 10mm

scale.

L2: Distance from the paper lead edge to the copy image lead

edge.

4) Press [EXECUTE] key. (The set value is saved.)

5) Make a copy at the magnification ratio of 100%, and adjust the

rear edge void.

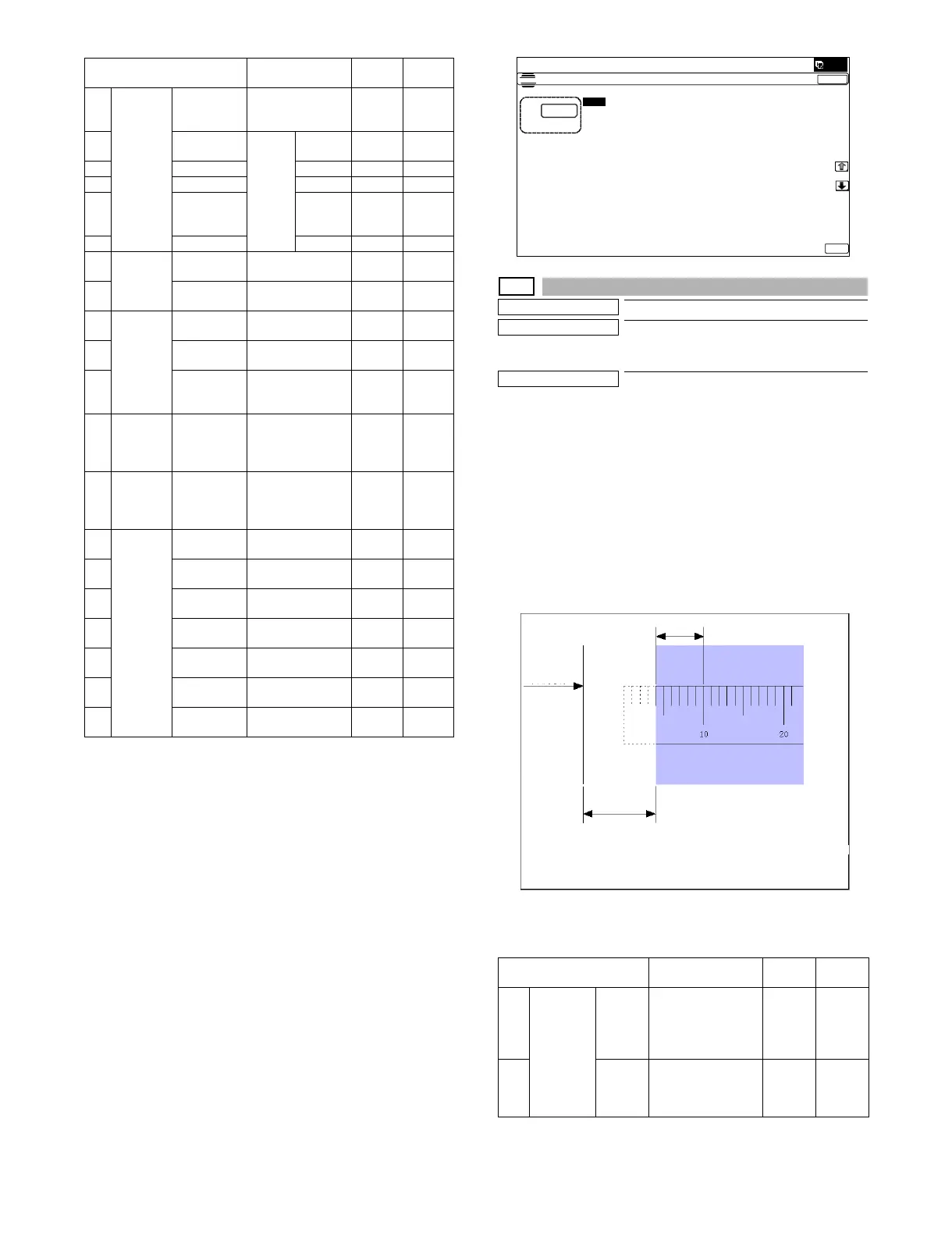

Item/Display Content

Setting

range

Default

value

A Lead

edge

adjust-

ment

value

RRCA Document lead

edge reference

position (OC)

0 - 99 50

B RRCB-CS12 Resist

motor

ON

timing

adjust-

ment

Standard

Tray

1 - 99 50

C RRCB-CS34 Desk 1 - 99 50

D RRCB-LCC LCC 1 - 99 50

E RRCB-MFT Manual

paper

feed

1 - 99 50

F RRCB-ADU ADU 1 - 99 50

GImage

loss area

setting

value

LEAD Lead edge image

loss area setting

0 - 99 30

H SIDE Side image loss

area adjustment

0 - 99 20

I Void area

adjust-

ment

DENA Lead edge void

area adjustment

1 - 99 30

J DENB Rear edge void

area adjustment

1 - 99 30

K FRONT/

REAR

FRONT/REAR

void area

adjustment

1 - 99 20

LOff-

center

adjust-

ment

OFSET_OC OC document off-

center adjustment

1 - 99 50

M Magnifica

tion ratio

correc-

tion

SCAN

_SPEED

_OC

SCAN sub

scanning

magnification ratio

adjustment (CCD)

1 - 99 50

N Sub

scanning

direction

print area

correction

value

DENB-MFT Manual feed

correction value

1 - 99 50

O DENB-CS1 Tray 1 correction

value

1 - 99 50

P DENB-CS2 Tray 2 correction

value

1 - 99 50

Q DENB-CS3 Tray 3 correction

value

1 - 99 50

R DENB-CS4 Tray 4 correction

value

1 - 99 50

S DENB-LCC LCC correction

value

1 - 99 50

T DENB-ADU ADU correction

value

1 - 99 50

Item/Display Description

Setting

range

Default

value

AActual

measurem

ent value

L1 Distance from the

image lead edge to

the scale of 10mm.

(Platen 400%,

0.1mm increment)

0 - 999 -

B L2 Distance from the

paper lead edge to

the image lead edge

(0.1mm increment)

0 - 999 0

ǂǂǂ6,08/$7,21

ǂǂ12

&/26(

7(67

/($'('*($'-8670(179$/8(

$˖

˷

˹

˖55&$

$˖

˖55&%

&6

%˖

˖55&%

&6

&˖

˖55&%

/&&

'˖

˖55&%

$'8

)˖

˖55&%

0)7

(˖

˖/($'

*˖

˖6,'(

+˖

˖'(1$,˖

˖'(1%

-˖

˖)5217

5($5

.˖

˖2)6(7

B2&

/˖

2.

Paper lead

edge

L1

L2

400% enlargement copy

Fig. 1

Loading...

Loading...