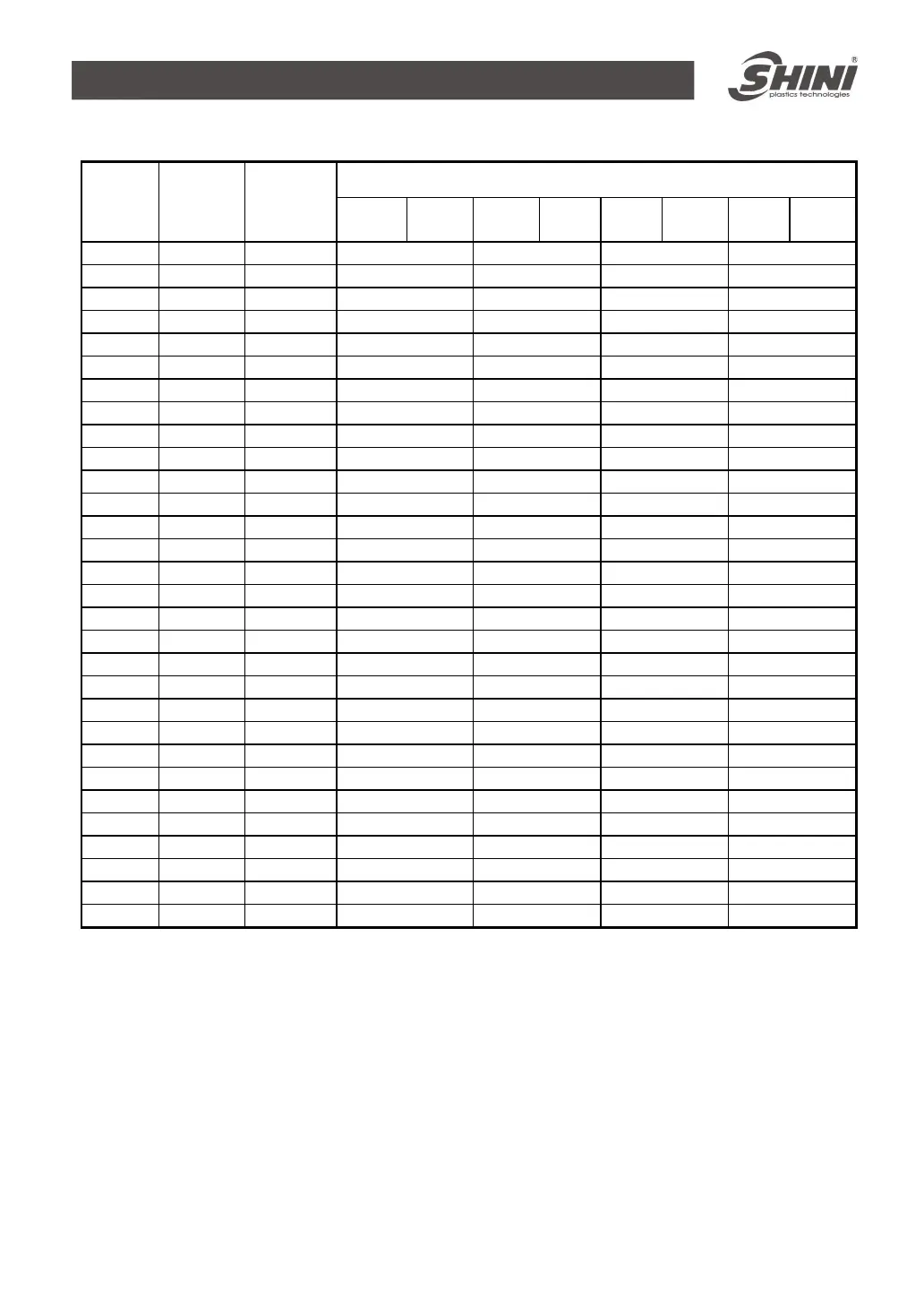

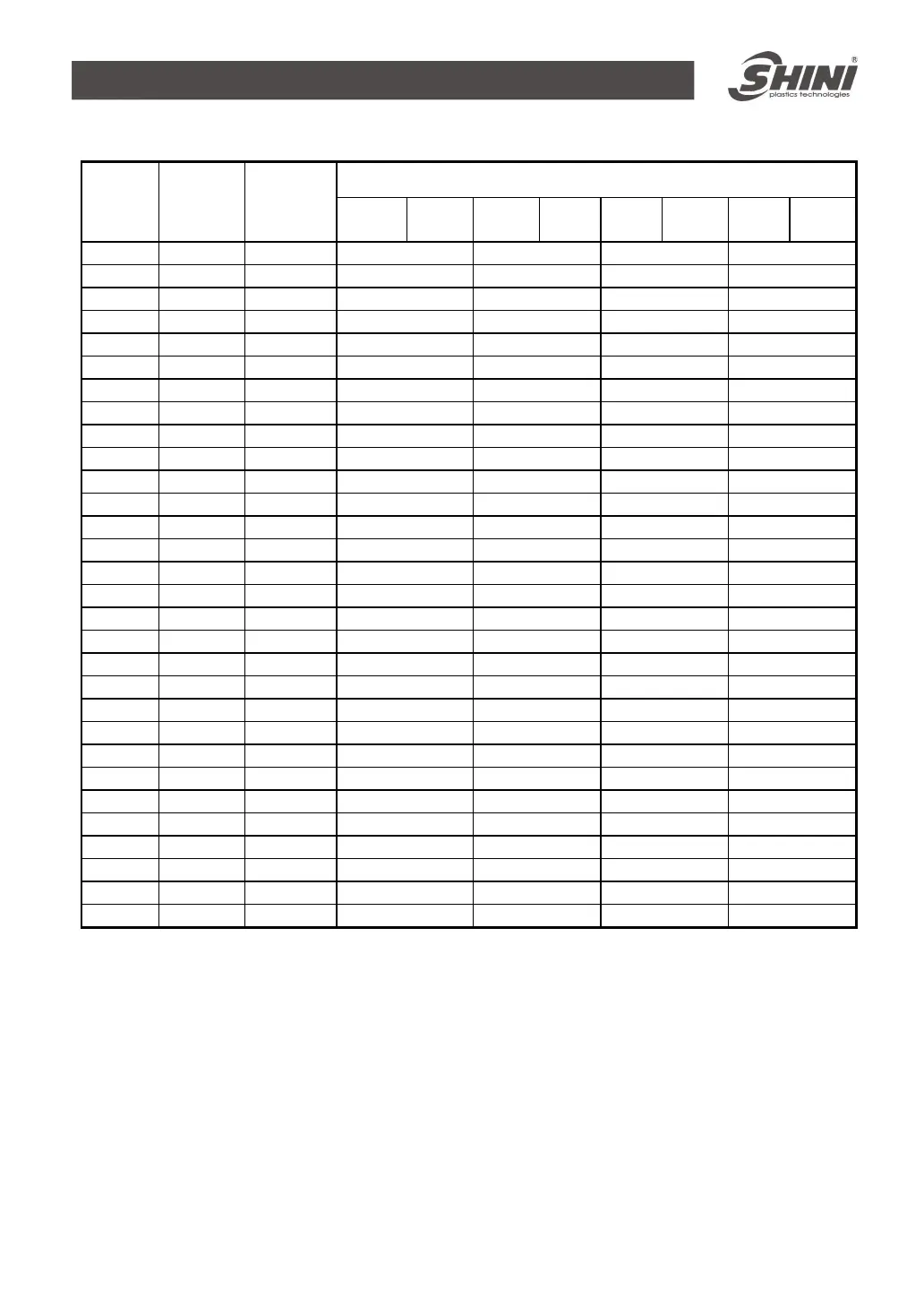

18(202)

Table 1-4:Drying Capacity 2

Drying Capacity (kg/hr)

Material

Drying

Temp. (℃)

Drying

Time

(hr)

450U

/300H

600U

/300H

600U

/400H

750U

/400H

750U

/500H

900U

/500H

900U

/700H

1200U

/700H

ABS 80 2-3 180 210 285 355

CA 75 2-3 150 180 235 295

CAB 75 2-3 150 180 235 295

CP 75 2-3 180 210 285 355

LCP 150 4 135 160 210 365

POM 100 2 265 320 425 530

PMMA 80 3 192 230 307 383

IONOMER 90 3-4 111 133 177 220

PA6/6.6/6.10

75 4-6 96 115 153 192

PA11 75 4-5 115 138 184 230

PA12 75 4-5 115 138 184 230

PC 120 2-3 206 250 330 413

PU 90 2-3 190 230 307 383

PBT 130 3-4 155 186 248 310

PE 90 1 531 637 850 1062

PEI 150 3-4 133 160 212 265

PET 160 4-6 125 150 200 250

PETG 70 3-4 133 160 212 265

PEN 170 5 150 180 240 300

PES 150 4 150 180 240 300

PMMA 80 3 190 230 310 385

PPO 110 1-2 220 265 355 440

PPS 150 3-4 133 160 212 265

PI 120 2 265 320 425 530

PP 90 1 442 530 710 885

PS(GP) 80 1 442 531 708 885

PSU 120 3-4 145 173 230 290

PVC 70 1-2 220 265 355 442

SAN(AS) 80 1-2 220 265 355 442

TPE 110 3 205 250 330 413

Note: 1. Please refer to above drying capacity of SCD machine, select the right model according to material

usage of processing machine.

2. Please consult Shini service staff for model selection.

Loading...

Loading...