COD.642400 Rev. 1

10

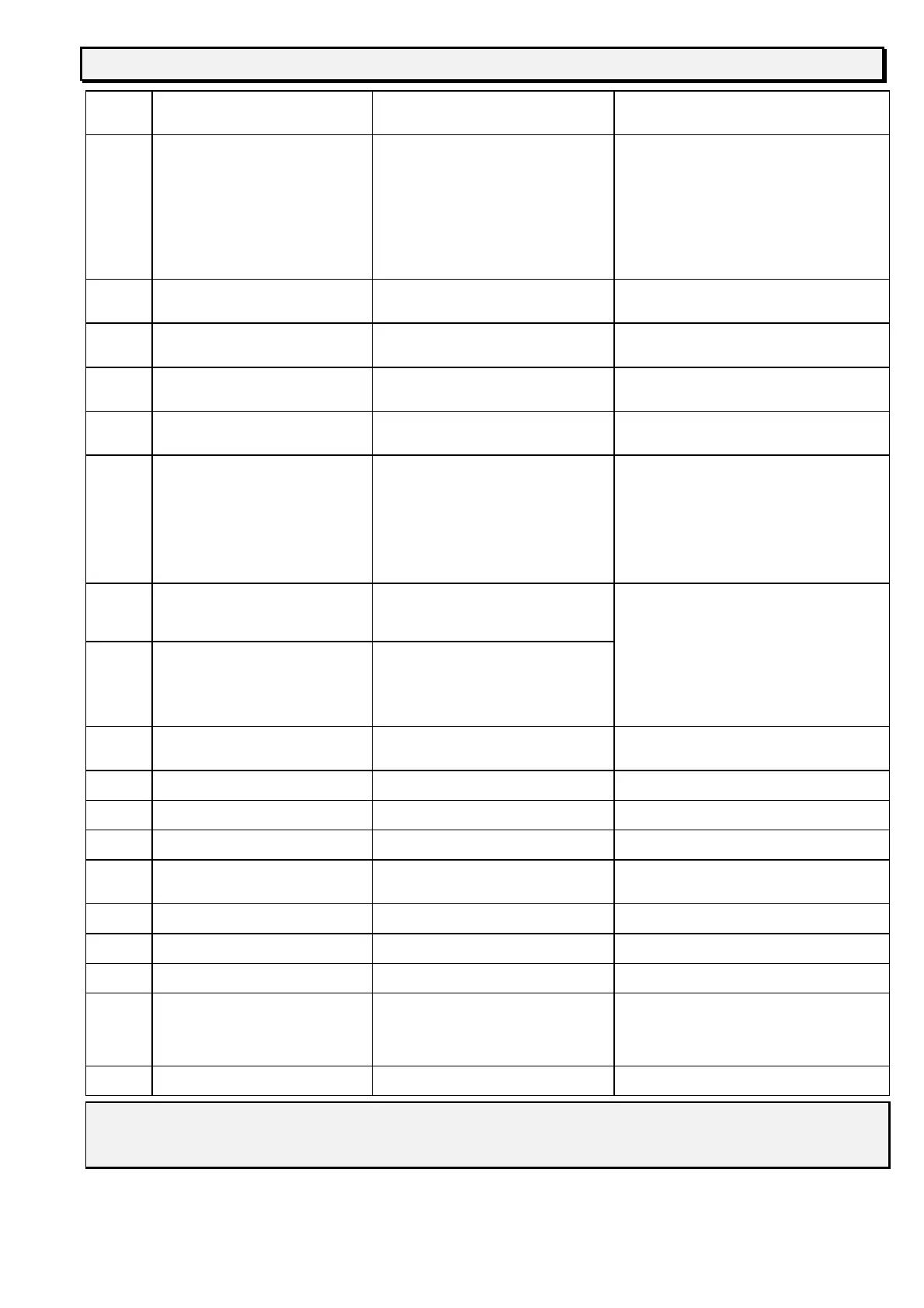

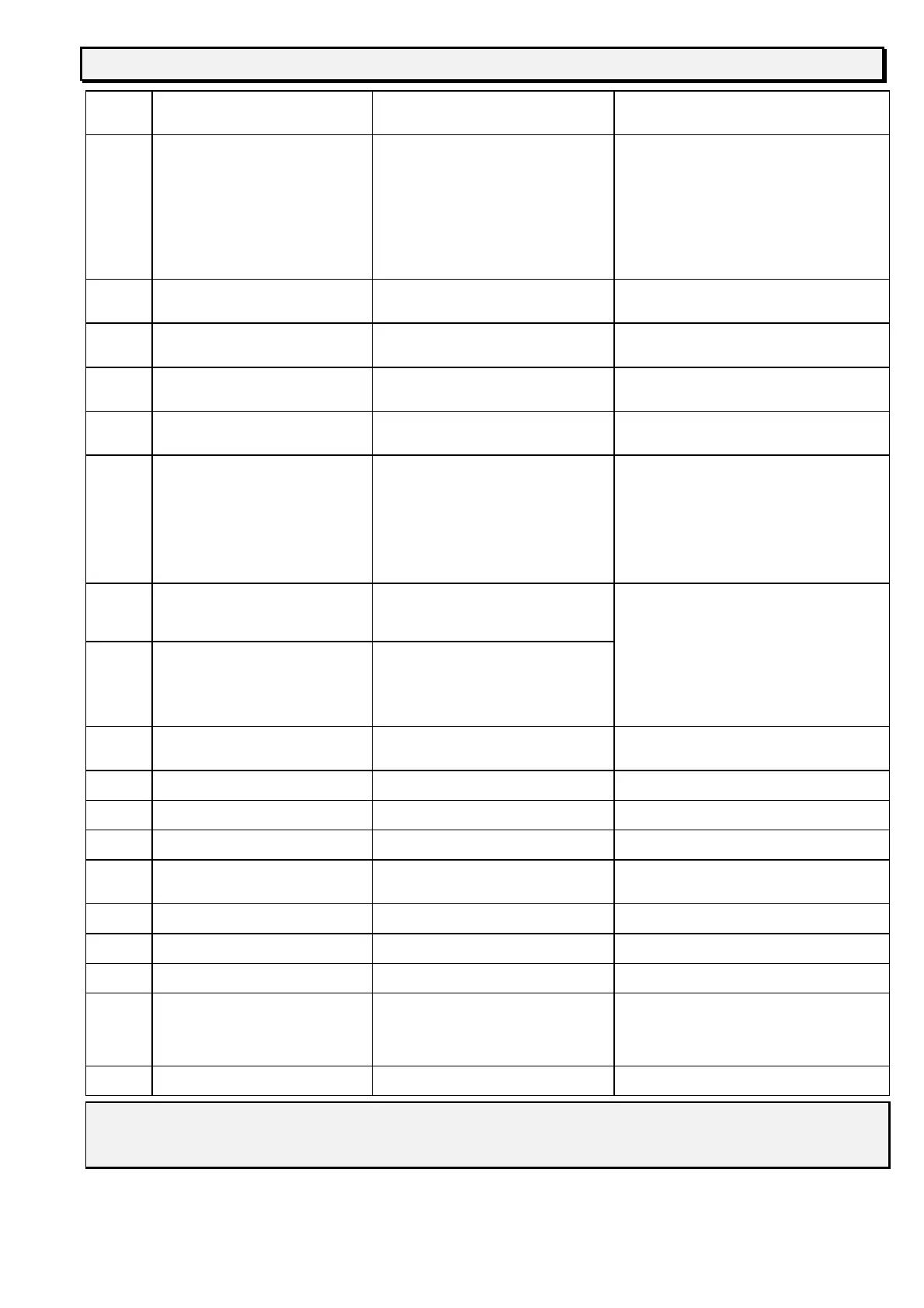

MALFUNCTIONS: CAUSES AND POSSIBLE REMEDIES

display malfunctions causes possible remedies

The

display

does not

light up

The panel has no power. 1. Lack of external supply or lack of one

phase.

2. Fuses F1 - F2 blown in the electrical

box. (See electrical circuit diagrams:

ref. 931801A - 931701A on pgs. 22-

25).

3. Fuses blown on the panel. (See

panel lay-out).

1. Check that all three phases (in the case of

three phase supply), or the single phase

and neutral, are connected to the balancing

machine.

2. Replace fuses F1 and F2. (The re-blowing

of the fuses suggests that there is a fault in

the electrical system).

3. Replace fuses F3 - F4 - F5. (The re-

blowing of the fuses suggests that there is

a fault in the electrical system).

E 00 Function non-existent error. 1. Wrong function code entered. 1. Establish the correct function code in the

present Instructions Manual or using help,

and enter it.

E 01 The message "E 01" appears when

switched on.

1. The electronic panel has lost the

settings pre-set during manufacture.

1. Repeat all the stages for setting the

balancing machine.

E 02 The message "E 02" appears when

switched on.

1. The electronic panel working

memory is faulty.

1. Replace the electronic panel.

E 03 The motor turns in the reverse

direction.

1. The motor supply is inverted 1. After switching off the main switch,

reverse 2 of the supply phases on the

balancing machine.

E 04

The motor does not turn (when

START is pressed), or the message

"E 04" appears after about 20

seconds.

1. Lack of one phase, if the motor is

three phase.

2. Relay malfunction in the electrical

box.

(See electrical circuit diagrams on

pgs.22-25).

3. Electronic panel malfunction.

the motor is not able to achieve the

necessary rotation for good

balancing.

1. Check that all 3 phases are correctly

connected.

2. Replace the electrical component.

3. Replace the electronic panel.

4. Check the mains tension, which may be

low.

E 05 After the second setting run "E 05"

appears on the display.

1. The sample weight was not screwed

on.

1. Re-start the setting cycle from the

beginning, or at the end of the first run

screw on the sample weight before

starting the second.

E 06 The message "E 06" appears when

START is pressed.

1. The guard casing has not been

lowered.

2. The guard casing micro-switch is

broken (see electrical circuit

diagram: ref.

931801A - 931701A on

pgs. 22-25).

1. Lower the mounted wheel guard casing.

2. Replace the micro-switch.

E 07 At the end of the first run "E 07"

appears on the display.

1. The difference of phase between the

two pick-ups is too great.

1. Replace the pick-ups. If after the

substitution the problem is not resolved,

replace the electrical panel.

E 08 At the end of the first run "E 08"

appears on the display.

1. The left pick-up is defective. 1. Substitute the left pick-up.

E 09 At the end of the first run "E 09"

appears on the display.

1. The right pick-up is defective. 1. Substitute the right pick-up.

E 10 At the end of the first run "E10"

appears on the display.

1. Position gauge fault. Optical-

electrical problem.

1. Replace the optical-electronics.

E 11 At the end of the first run "E11"

appears on the display.

1. Movement gauge fault. Problem with

the optical-electrical zero point.

1. Replace the optical-electronics.

E 14 "E14" appears on the display. 1. +5V supply incorrect. 1. Replace the electrical panel.

E 15 "E15" appears on the display. 1. +8V supply incorrect. 1. Replace the electrical panel.

E 16 "E16" appears on the display. 1. -12V supply incorrect. 1. Replace the electrical panel.

E 17 At the end of the first run "E 17"

appears on the display.

1. Weight outside the range of

adjustment (the weight necessary to

balance the wheel is greater than

250 grams).

1. a) check that the wheel is correctly fitted

to the flange.

b) look for (equally) the external position,

fit a 100 gram weight and run the

balancer.

E 18 At the end of the first run "E18"

appears on the display.

1. Wheel data not entered. 1. Enter the wheel data on the keyboard.

Other possible malfunctions are largely technical

in nature and must be checked and resolved by

PROFESSIONALLY QUALIFIED TECHNICIANS.

Loading...

Loading...