COD.642400 Rev. 1

13

PROGRAMMING FOR WHEEL BALANCING

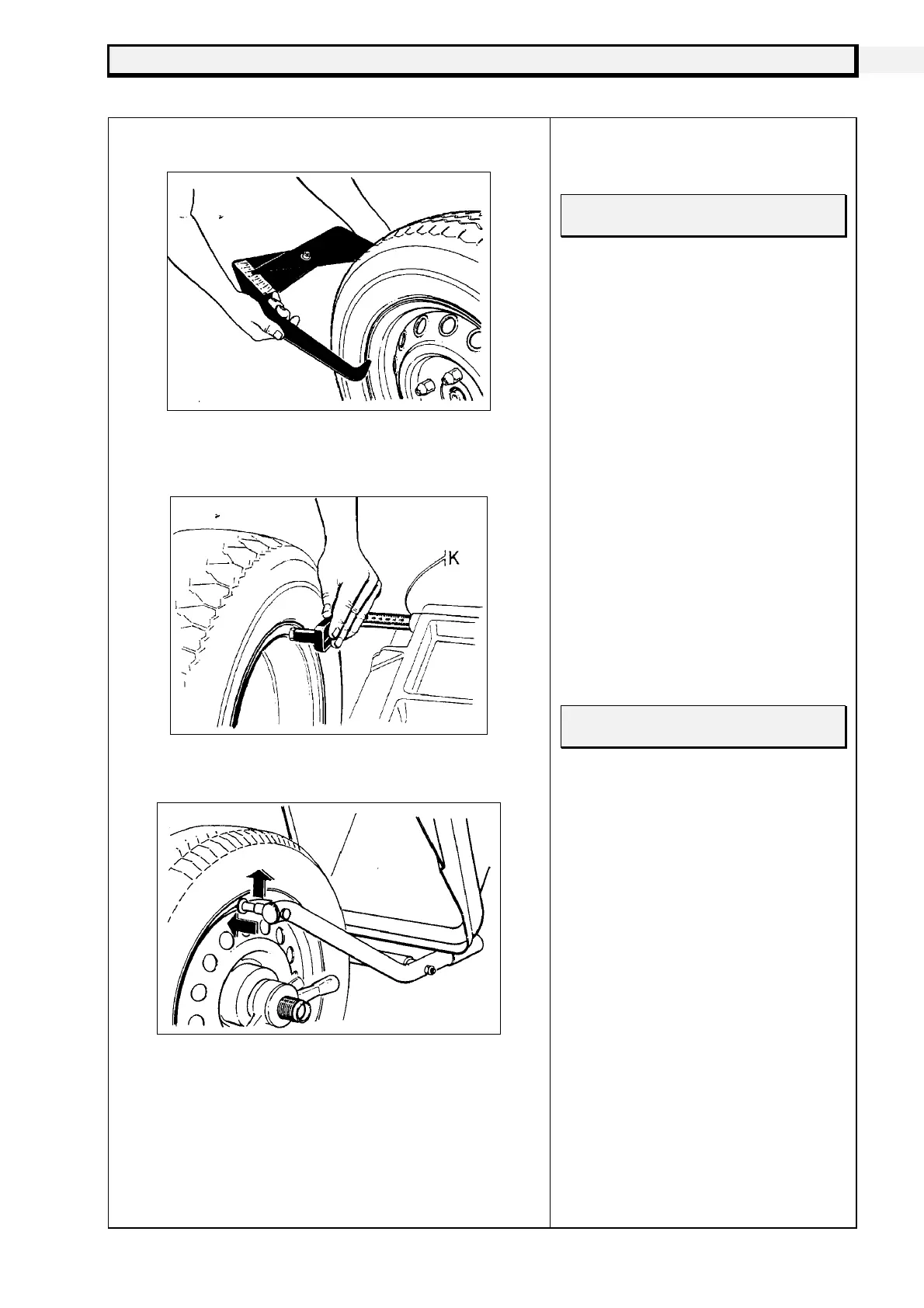

fig17

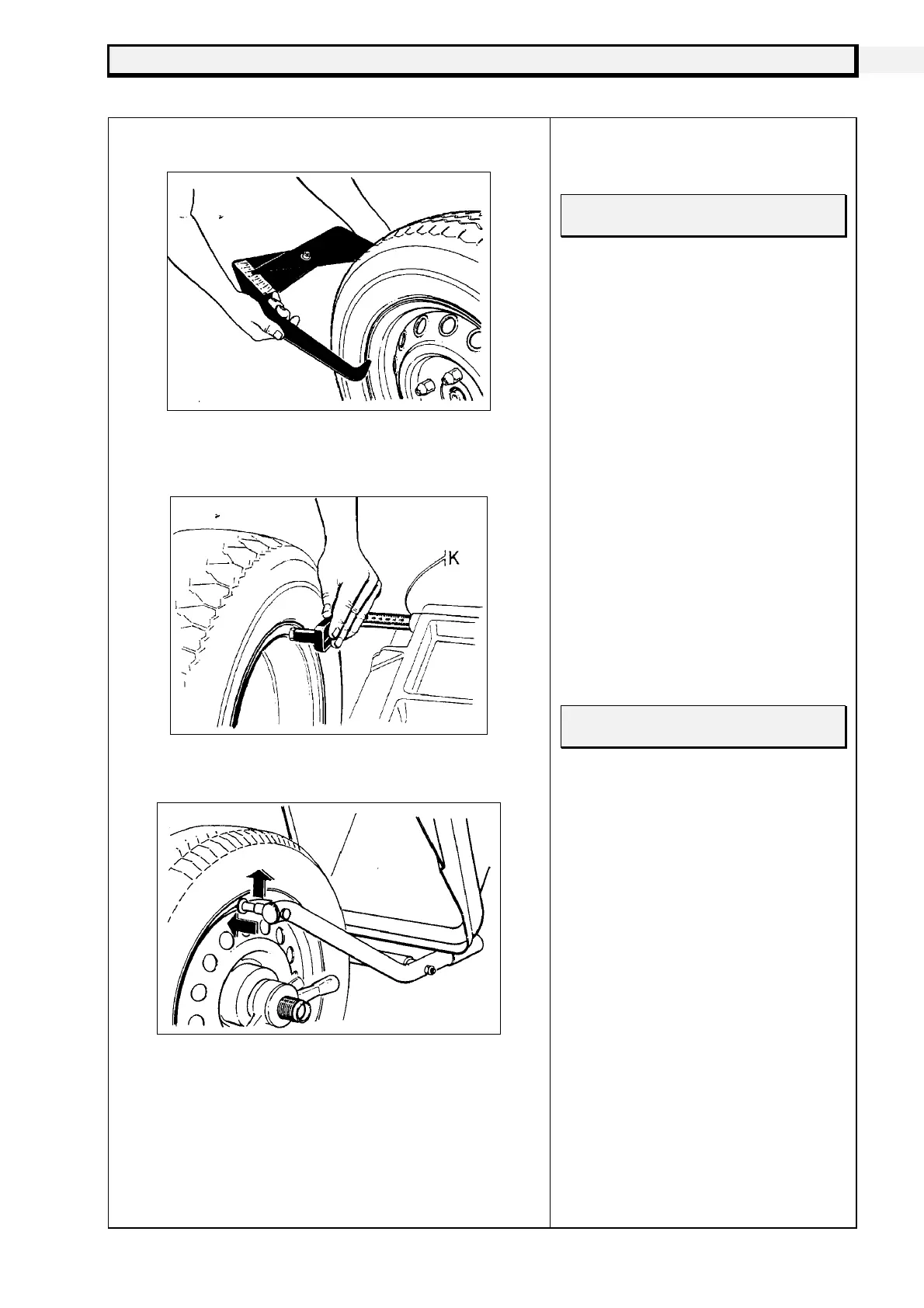

K = reading point

fig.18

fig.19

PROGRAMMING WITH

MANUAL GAUGE

Set the figures of the width, diameter,

and rim compensation distance of the

wheel which is to be balanced, on the

control panel. The width is measured

using the calliper gauge supplied with

the machine (fig. 17). The diameter of

the rim is read on the tyre, and the rim

compensation distance is measured

with the gauge cursor on the machine

(fig. 18). The compensation distance

figure to be set is read on the scale.

If only the static imbalance is to be

determined, as with motorcycle wheels,

only the rim diameter has to be set on

the programmer (2), (see fig. 15). The

other two readings can be set at any

figure.

PROGRAMMING WITH

AUTOMATIC GAUGE

Programming is effected by positioning

the internal gauge (fig. 18) and the

external gauge (fig. 19) against the rim

and waiting for the confirmation "beep'".

The figures to programme (distance,

width and diameter) are automatically

inserted into the panel. It is a single

operation - extremely fast and

completely error free.

Loading...

Loading...