COMMISSIONING AND OPERATION 5

8024534 / 16UW / 2020-02-26 Operating Instructions | InspectorP Rack Fine Positioning 33

Subject to change without notice

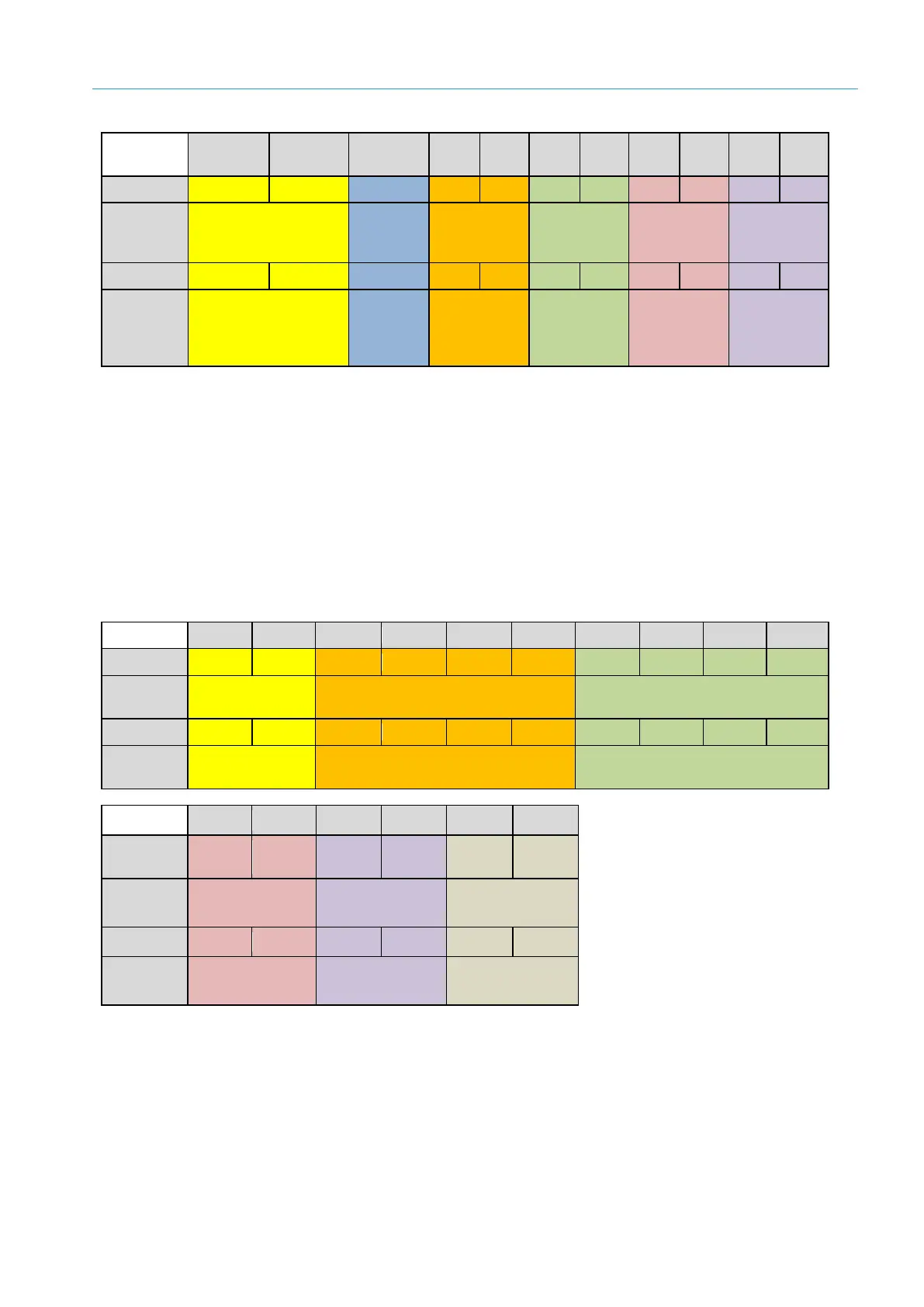

Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7 Byte 8 Byte 9

Byte

Byte

Function

Command Selection

Relative offset

to origin X in

Relative offset

to deviation Y in

Tolerance X in

1/10 mm

Tolerance Y in

1/10 mm

example 6 Specialist double deep

parameterization

“8 best

circle

diameter

0/10 mm

= 0 mm

0/10 mm

= 0 mm

80/10 mm

= 8 mm

80/10 mm

= 8 mm

The Selection (evaluation mode) parameter in byte 3 is evaluated as BYTE in the

controller. All other parameters are evaluated as WORD in byte 4 to byte 11.

As a response to specialist double deep parameterization, the device sends status

bytes <00><80>. These status bytes are reset to <00><00> after successful

parameterization.

Other parameters cannot be set by the host.

5.4.4 Response from the device to the controller

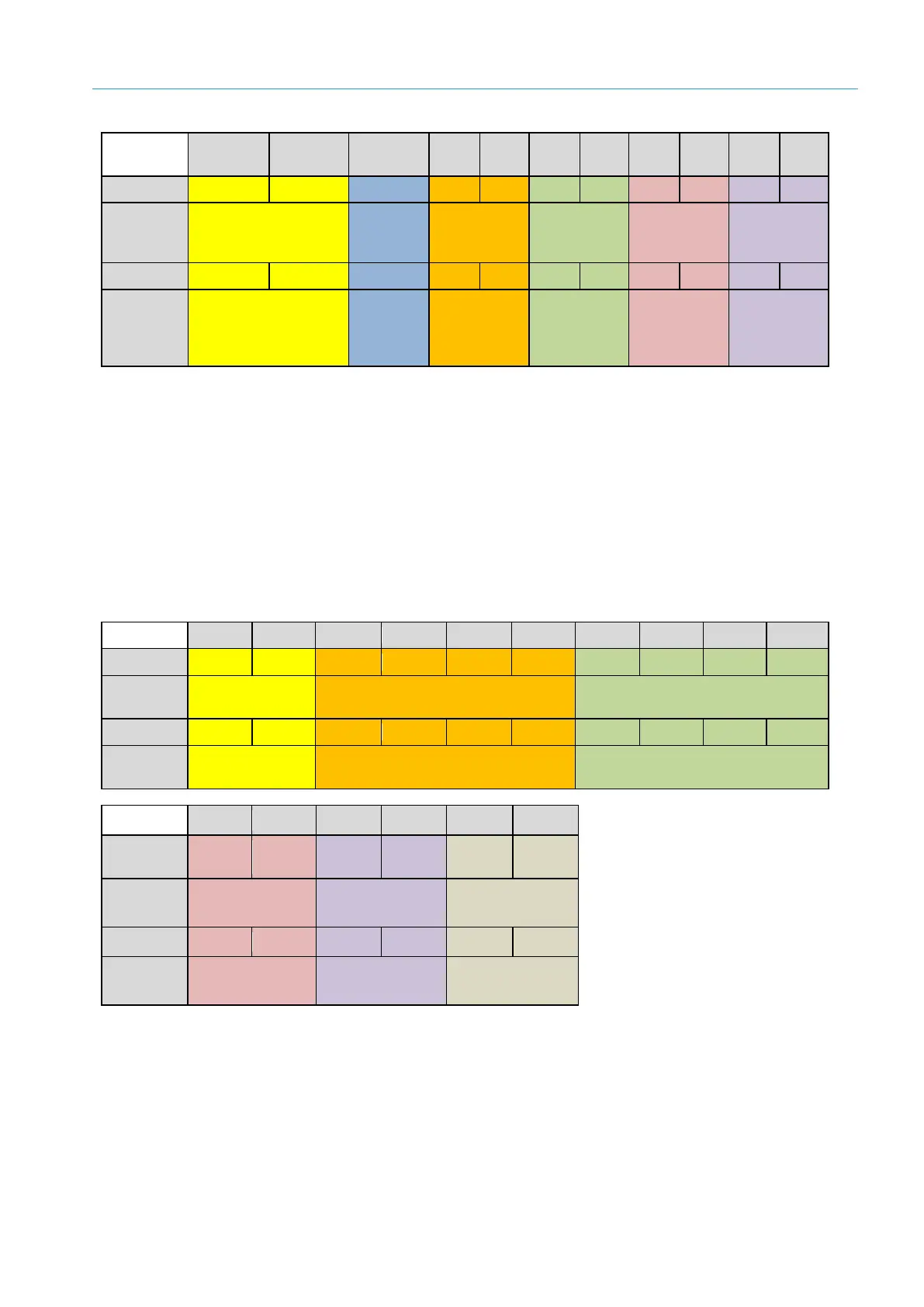

As long as continuous measurement is switched on, the device cyclically transmits

measurement results to the controller.

For each image, 16 bytes are reported back to the controller from the device.

Function

Status

Automated storage and retrieval system

relative position correction X in µm

Automated storage and retrieval system

relative position correction Y in µm

Circle found 16,558 µm - 4,906 µm

Byte 11 Byte 12 Byte 13 Byte 14 Byte 15 Byte 16

Designation

PicNr_H PicNr_L

Proc

Proc

Dia

Dia

Function

Image counter Evaluation time in ms

Evaluation of the

circle diameter in %

Example 4

<8E> <DC> <00> <27> <00> <6C>

example 4

36572 39 ms 108%

Loading...

Loading...