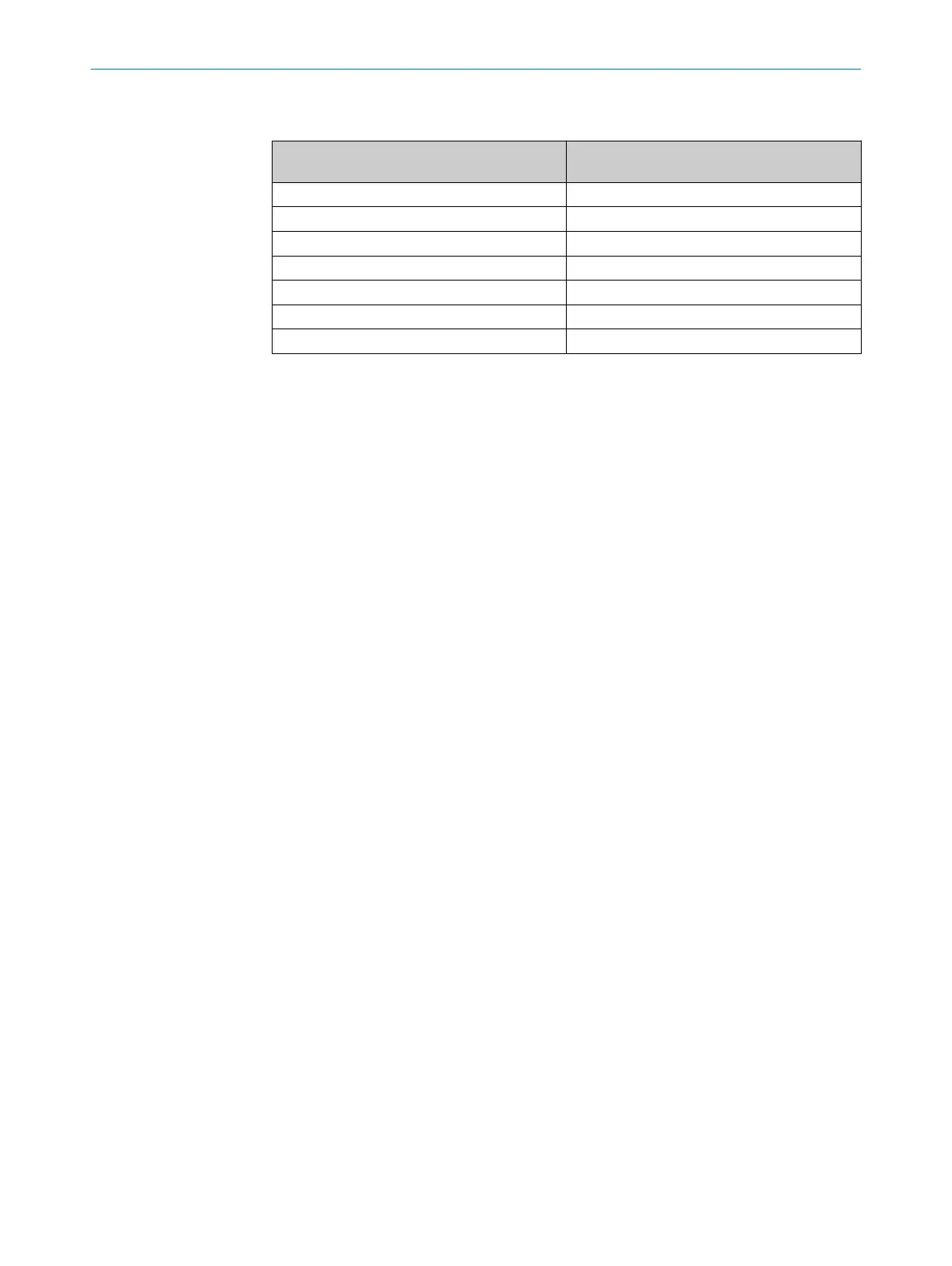

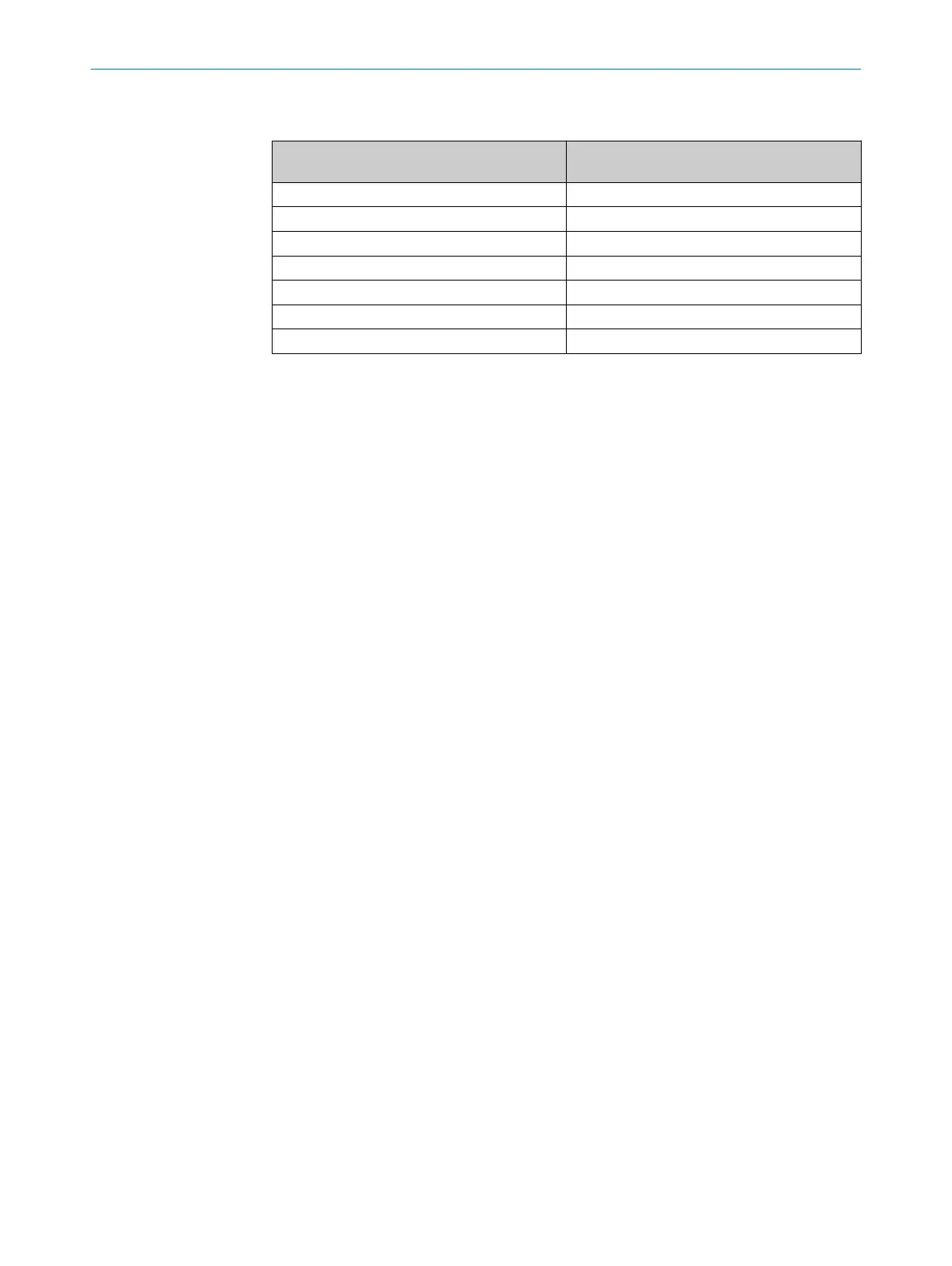

Table 4: Maximum number of cascadable safety switches in relation to the total length of the cas‐

c

ade

Maximum number of cascadable safety

s

witches

Total length of the cascade

1)

1 140 m

2 70 m

3 46 m

4 35 m

5 28 m

6 22 m

7 20 m

1)

At a cable cross-section of 0.34 mm²

If a cascade has more safety switches or gets longer, additional voltage must be fed in

v

ia a node for voltage supply.

4.5 Thorough check concept

The safety switch must be tested by appropriately qualified safety personnel during

commis

sioning, after modifications, and at regular intervals; see "Thorough check",

page 30.

Regular thorough checks serve to investigate the effectiveness of the safety switch and

discover defects resulting from modifications or external influences (such as damage or

manipulation).

The manufacturer and operating entity must define the type and frequency of the thor‐

ough checks on the machine on the basis of the application conditions and the risk

assessment. The process of defining the thorough checks must be documented in a

traceable manner.

4.5.1 Minimum requirements for the regular thorough check

The following thorough checks must be carried out at least once a year:

•

T

horough check of the protective function of the safety switch

•

Thorough check of the switch housing for damage

•

Thorough check of the switch cables for damage

•

Thorough check of the safety switch for signs of misuse or manipulation

•

Thorough check of the locking solenoid for correct function

PROJECT PLANNING 4

8020169/ZJN1/2018-03-21 | SICK O P E R A T I N G I N S T R U C T I O N S | MLP1

19

Subject to change without notice

Loading...

Loading...