•

Unbalance

•

Misalignment

•

Relaxation

As with the a-RMS, the sensor for the v-RMS also provides the magnitude, the effective

value of the sum vector of all three axes, which represents the energy contained in the

vibration without directional separation.

9.3.1.3 Limit values based on ISO 10816 (Index 4534-4536)

The ISO10816-3 standard defines limit values that indicate whether v-RMS amplitudes

are acceptable when operating rotating machines. Here, 4 evaluation zones are

defined, which describe the machine condition on the basis of the v-RMS vibration

values.

The limit values shown in table 11 can be set automatically in the sensor by specifying

the machine type and the associated subassembly.

Machine group 1: Nominal power >300kW and <50MW, axis height ≥315mm

Machine group 2: Nominal power >15kW <300kW, axis height 160mm ≤ and

<315mm

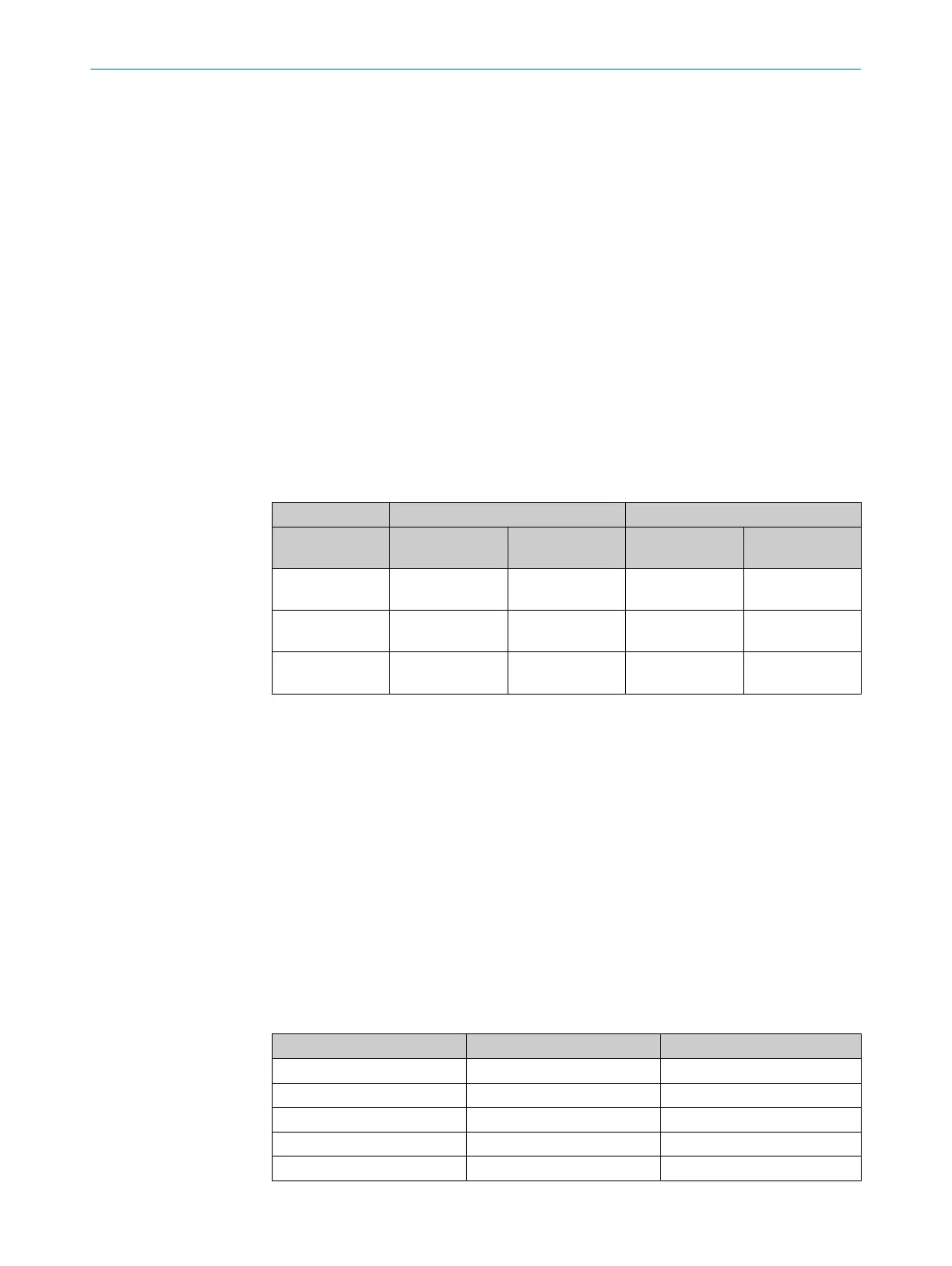

Table 11: v-RMS limit values based on ISO 10816-3

Machine group Machine group 1 Machine group 2

Substructure Elastic substruc‐

ture

Rigid substruc‐

ture

Elastic substruc‐

ture

Rigid substruc‐

ture

Zone limit C/D

[mm/s]

11 7.1 7.1 4.5

Zone limit B/C

[mm/s]

7.1 4.5 4.5 2.8

Zone limit A/B

[mm/s]

3.5 2.3 2.3 1.4

Zone

D

Machines that have vibrations in this range can be damaged.

Zone

C

Machines that have vibrations in this range can run in limited operation. Continuous operation is not

considered suitable.

Zone

B

Machines that have vibrations in this range can run without restrictions.

Zone

A

Newly commissioned machines exhibit vibrations in this area.

The configuration of the sensor for monitoring based on ISO 10816-3 is done via Index

4535. When writing to this index, the corresponding limit between zone B and C is

automatically set as the pre-maximum limit value for v-RMS. The limit between zone C

and D is set as the maximum limit value. The zone boundaries are also automatically

entered in Index 4536. The limits in ISO 10816-3 are defined considering a frequency

range of 10-1,000Hz, therefore this frequency range is also configured in the sensor.

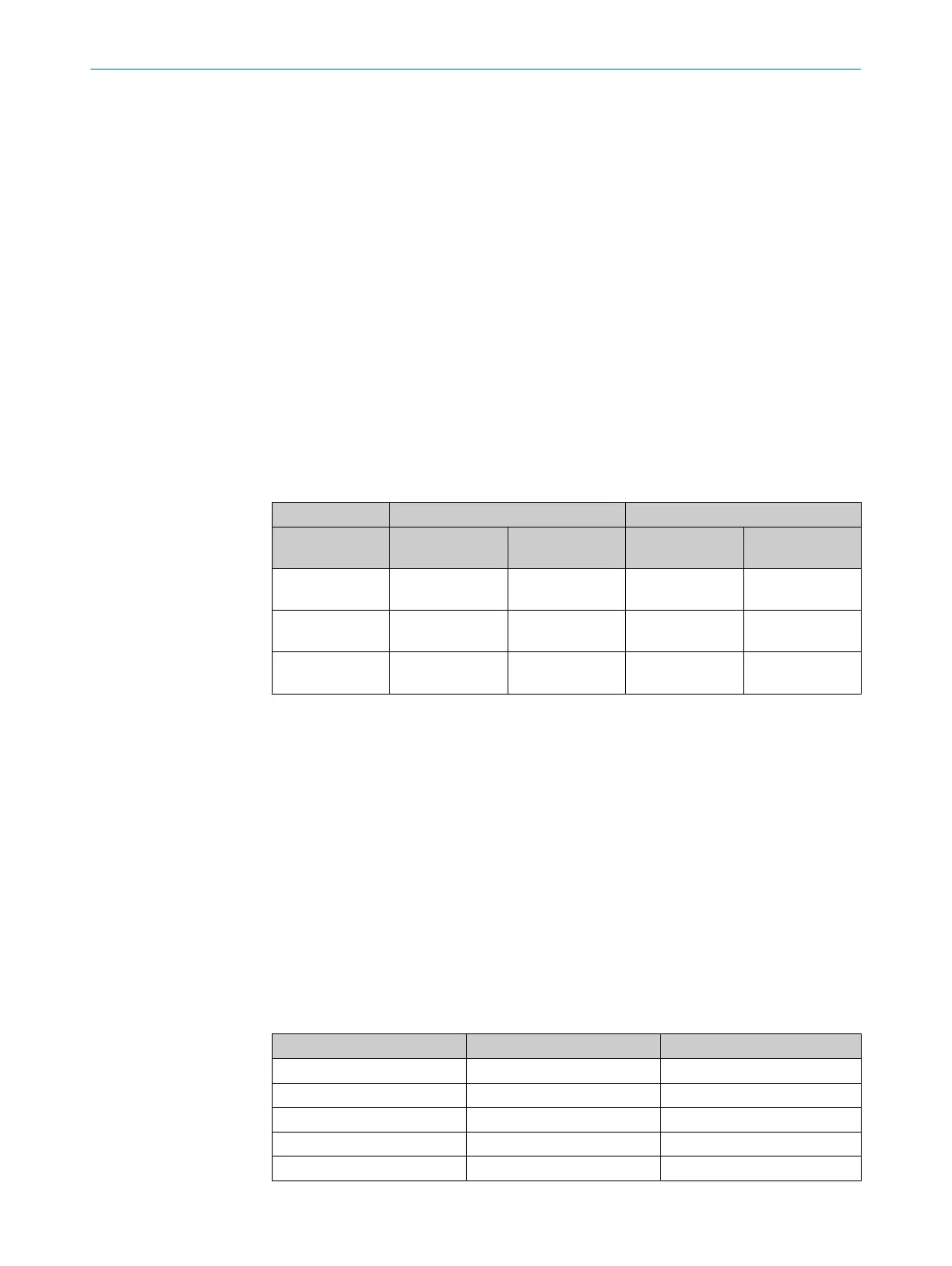

In table 12, an example of parameterization for a machine from group 1 with a rigid

substructure and a current v-RMS of 3.5 mm/s is shown. Index 4534 can be used to

read out in which evaluation zone the plant falls with the currently measured v-RMS

value.

Table 12: Example parameter ISO 10816

Index Content Value

4534 Current evaluation zone 2 = Zone B

4535 Preselection 1 = Group 1: elastic

4536 (Subindex 3) Zone border C/D 7.1mm/s

4536 (Subindex 2) Zone border B/C 4.5mm/s

4536 (Subindex 1) Zone border A/B 2.3mm/s

OPERATION 9

8028041/2022-08-16 | SICK O P E R A T I N G I N S T R U C T I O N S | MPB10

33

Subject to change without notice

Loading...

Loading...