SH100/185T- SH160/215T - SP 220 HYD - SP 300 HYD - SP 550 HYD 2.5 - 2008

1. Die Mittellinie von Tunnel und Boot markieren. Damit Schub-

richtung und Kontrollpanel übereinstimmen, das Getriebege-

häuse so einbauen, daß der Verschluß des Getriebegehäuses

(der verschraubte Verschluß hinter einem der beiden Pro-

peller) Richtung Steuerbord zeigt.

2. Die Löcher mit der Dichtung (7) markieren. Maße überprüfen!

Den Thruster schiffssmittig plazieren (Fig. 1). Da der Abstand

zwischen Propellern und Tunnel wegen größtmöglicher

Performance minimal konstruiert ist, müssen für eine präzise

Installation alle Löcher auf der Tunnelmittellinie liegen.

3. Im Bereich der Motorhalterung darf kein Laminat auf dem

Tunnel sein, da dies zu einem Getriebeschaden führen

kann. Liegt die Motorhalterung nicht eben auf dem Tunnel

auf, so sind sämtliche Unebenheiten in diesem Bereich

abzuschleifen.

4. Bohren Sie das Zentrumsloch und dann die beiden

Schraubenlöcher.

5. Das Getriebegehäuse unter Verwendung der Dichtung in

den Tunnel einpassen. Den Propeller auf die Achse stecken;

dieser muß sich frei bewegen lassen und jedes Propellerblatt

muß den gleichen Abstand zum Tunnel aufweisen. Ist die

Tunnelinnenseite ungleichmäßig, etwas Sikaex o.ä. auf-

tragen, damit keine undichte Stelle auftritt.

6. Das Getriebegehäuse durch das Hauptloch im Tunnel führen

und vorsichtig mit der Motorhalterung zusammenschieben.

7. Das Getriebegehäuse und die Motorhalterung mit Hilfe der bei-

den Bolzen verschrauben (Anzugsmoment 17 Nm / 12,4 lb/ft).

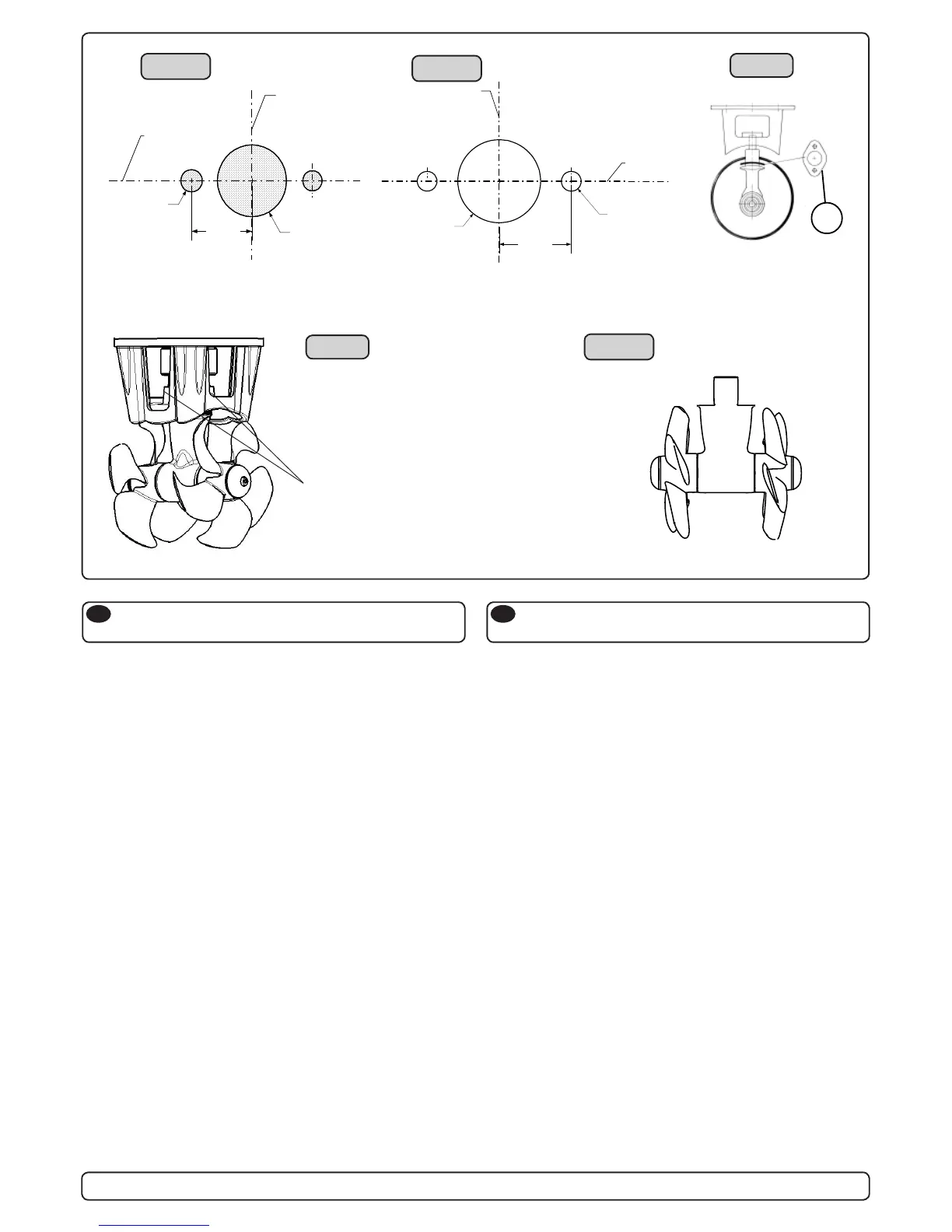

1. Mark the centreline of the tunnel and the boats centreline.

The gearhouse must be tted with the gearhouse lid (the

screwed in lid behind one of the propellers) on the starbord

side of the boat for the thrust direction to correspond with the

controlpanel.

2. Use the gearhouse gasket (7) to mark the centre of the holes

and double check the measurements.

Place the thruster in the boats centreline with the bolt hole as

the centre (Fig. 1a / Fig 1b). It is absolutely necessary that all

holes are in-line with the tunnels' centreline to ensure precise

installation, as the clearance between the propellers and the

tunnel is minimal to ensure best possible performance.

3. There must be no casting where the motor bracket is to be

placed, as this will cause possible failure of the gearhouse.

The motor bracket must t steady on the tunnel, if the tunnel

is not smooth, all bumps or uneven parts must be grinded

smooth.

4. Drill the centre-hole and then the two screw-holes, SH100

dim. according to g 1a, SH160 dim. according to g. 1b

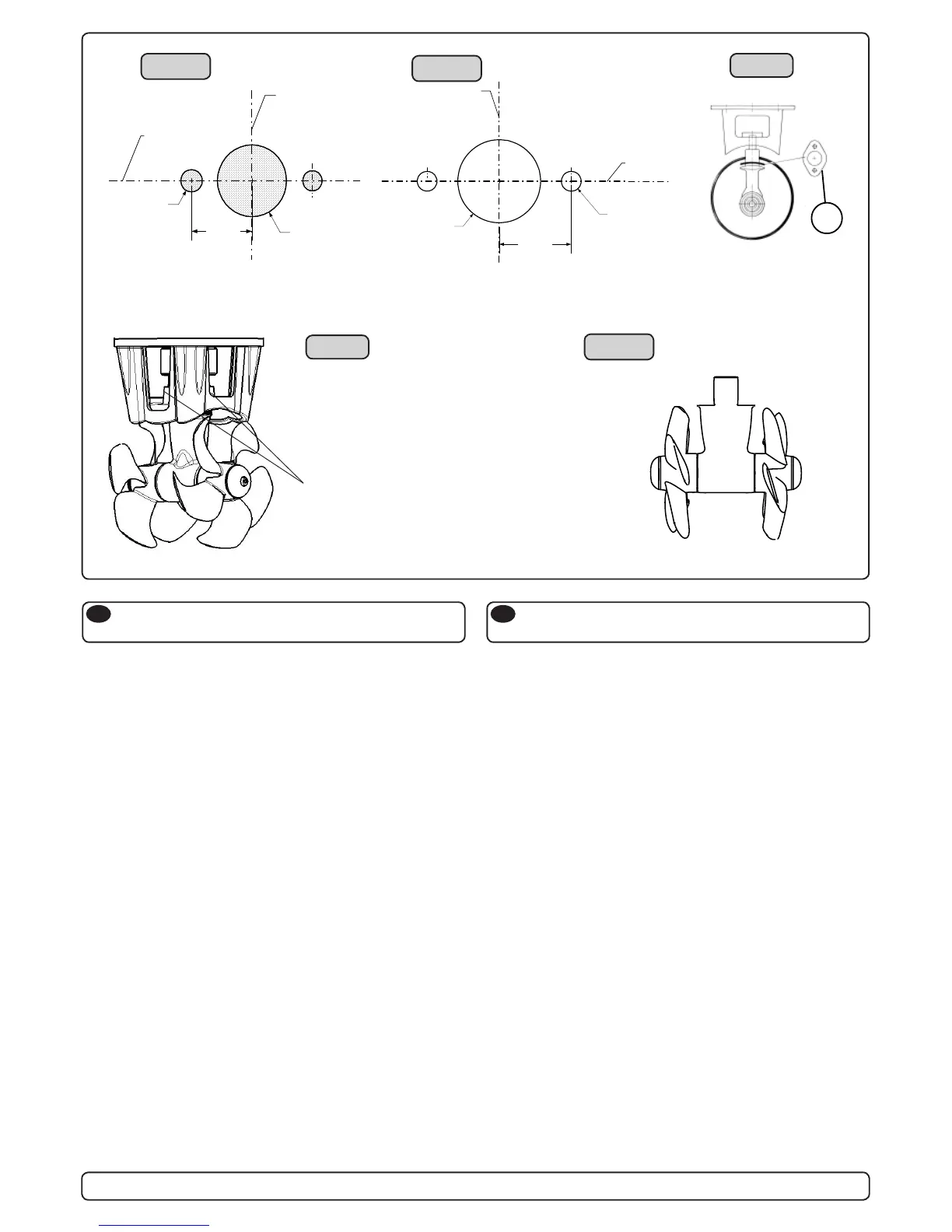

5. Try the lower-unit in the tunnel by using the gasket inside

the tunnel. Try on the propellers to make sure they are in the

middle of the tunnel and turn freely with the same clearing

from each blade to the tunnel. If the tunnel is not plain, use

some Sikaex or other sealant to ensure that no leakages

occur.

6. Push the gearhouse through the main hole in the tunnel and

push the gearhouse and motor-bracket gently together.

7. Screw the lower unit and the motor-bracket together with the

two provided bolts. Tighten with 17 Nm / 12,4 lb/ft.

Getriebe und Motorhalterung

SH 100/185 T

D

Fitting gearhouse and motor bracket

SH 100/185 T & SH160/215T

GB

13

11

SE 80/185 T - SE 100/185 T - SE 130/250T 1.0.1- 2008

Fig. 2

1. Marker båtens og tunnelens senterlinje på tunnelen.

Girhuset må plasseres med enden merket P mot babord og enden

merket S mot styrbord (Fig. 4) for at skyveretning skal korrespondere

med merkingen på kontrollpanelene.

2. Bruk girhuspakningen for å sjekke målene (7). Alle hull må være på

båtens eller tunnelens senterlinje for å får til en presis installasjon.

Dette skyldes at det er meget liten klaring mellom tunnelveggen og

propellen.

3. Tunnelen må ha en jevn overate der braketen skal festes, all støp,

evt glassber eller epoxy rester må pusses ned så braketen passer

jevnt på tunnelen. Ujevnheter her vil resultere i svikt i girhuset.

4. Bor senterhullet iht. Fig. 1a (Se80/100) eller Fig. 1b (SE130)

5. Prøv girhuset i tunnelen sammen med pakning 1m.m. Monter propell

å sjekk at den er i midten av tunnelen. Hvis propellen ikke er i midten

av tunnelen, forsøk å bruk den endre pakningen, eller begge to sam-

tidig. Hvis tunnelen ikke har en jevn overate så kan Sikaeks, eller

lignende tetningsmateriale brukes for å sikre mot lekkasje.

6. Før girhuset gjennom hovedhullet i tunnelen og monter braketten og

girhuset forsiktig sammen.

7. Skru sammen motorbraketten og girhuset med orginalbolter (Fig. 3).

Bolt tightening forces:

Bolts (2x) holding gearhouse to bracket:

SE80/100: 17 Nm (12,4 lb/ft)

SE130: 33 Nm (24lb/ft)

Montering av girhus og brakett

N

Fitting gearhouse and motor bracket

GB

Fig. 1a

PORT STARBOARD

S

P

Fig. 4

Fig. 3

1. Mark the centreline of the tunnel and the boats centreline.

The gearleg must be tted with the P-mark facing port and S-mark

facing starboard (Fig. 4) for the thrust direction to correspond with the

control panel

2. Use the gearhouse gasket (7) to mark the centre of the holes and

double check the measurements. It is absolutely

necessary that all holes are in-line with the tunnels’ centreline to

ensure precise installation, as the clearance between the

propellers and the tunnel is minimal to ensure best possible

performance.

3. There must be no casting where the motor bracket is to be placed,

as this will cause possible failure of the gearhouse. The motor

bracket must t steady on the tunnel, if the tunnel is not smooth,

all bumps or uneven parts must be grinded smooth.

4. Drill the holes according to Fig 1a (SE80/100) or Fig. 1b (SE130)

5 Try the lower-unit in the tunnel (without the zinc anodes and the

lower part of the exible coupling) by using the gasket inside the

tunnel. Try on the propellers to make sure they are in the middle of

the tunnel and turn freely with the same clearing from each blade to

the tunnel. Use sealant e.g. Sikaex to ensure that no leakages

occur.

6. Push the gearhouse through the main hole in the tunnel and push

the gearhouse and motor-bracket gently together.

7. Screw the lower unit and the motor-bracket together with the two

provided bolts (Fig. 3).

Loading...

Loading...