SH100/185T- SH160/215T - SP 220 HYD - SP 300 HYD - SP 550 HYD 2.5 - 2008

Im Vorratsbehälter muß immer Öl vorhanden sein. Falls nötig

mit Getriebeöl EP90 nachfüllen.

Das Getriebeöl mindestens alle zwei Jahre wechseln. Die Quali-

tät des Getriebeöls immer überprüfen, wenn das Boot auf

Land liegt.

Die Bolzen, die das Getriebegehäuse mit der Motorhalterung

verbinden, beim ersten Service an Land mit dem angegebe-

nen Anzugsmoment (s. Seite 14/15) entsprechen nachziehen.

Vor jeder Saison auf Propeller und Getriebegehäuse Antifouling

aufbringen.

PS ! Zinkanode, Dichtungen und Propellerachse frei von

Antifouling halten. Die Aussparungen im Getriebegehäuse

nicht mit Anti-Fouling "füllen", da hier die Propellernabe

läuft.

Die Zinkanode vor jeder Saison oder wenn diese zur Hälfte ab-

genutzt ist ersetzen. Zur Sicherung der Befestigungsschraube

der Zinkanode immer Locktite o.ä. verwenden. Bitte beachten

Sie, daß unter bestimmten Milieubedingungen eine zusätzli-

che Zinkanode nötig sein kann, damit der Korrosionsschutz

gewährleistet ist, solange sich das Boot im Wasser bendet.

Hierzu kann Ihnen Ihr Händler nähere Informationen geben.

Bei jedem Service und vor jeder Saison sollte folgendes über-

prüft werden:

• Der Propeller ist sicher befestigt.

• Die Bolzen, die den Motor auf der Motorhalterung befestigen

sind korrekt angezogen.

• Die Umgebung des Thrusters ist sauber und trocken. Bei

Wassereinbruch, muß der Grund dafür beseitigt werden.

• Alle elektrischen Verbindungen sind sauber und fest.

• Sicherstellen, daß am Thruster ausreichend Spannung anliegt.

Alte oder mangelhafte Batterien reduzieren die Leistung und

sollten ausgetauscht werden.

Wartung

D

All models except SH 100/SH160: There must always be oil in

the oil reservoir. Rell if necessary with gear oil EP90.

All models except SH 100/SH160: Change the gear oil a

minimum of every second year. Check the gearoil quality in the

gearhouse every time the boat is out of the water.

Retighten the bolts holding the gearhouse to the motorbracket

during the rst on-land service with the specied bolt tightening

force (see page 14/15).

Keep the propeller and gearhouse clean from growth by painting

with antifouling before every season.

PS ! The zinc anode, sealing and propeller shafts must

abso-lutely not be painted. Be careful that you don't ll

paint in the "tracks" in the gearhouse that the propeller

hub moves in.

Change the zinc anode before every season, or when about

half the anode is gone. Always use a sealant on the screw

holding the zincanode to ensure that it does not fall off. Please

observe that in some waterconditions it can be necessary to

install an extra zincanode to ensure that it lasts for the whole

period between regular service lifts of the boat. Consult your

dealer for information on how to do this.

As a part of the seasonal service of your boat, and before

every season, always check that:

• The propeller is securely fastened

• The bolts holding the electric motor to the motorbracket are

fastened correctly.

• The area where the thruster is installed is clean and dry. If there are

signs of water you must try to nd the source and eliminate it.

• All electrical connections are clean and fastened rmly.

• Make sure that your batteries are in a good condition so that

the thruster gets a good voltage. Old or bad batteries will give

a reduced performance from the thruster.

Maintenance

GB

21

n

o

q

p

r

s

t

**

**

* Im Vorratsbehälter muß immer Öl vorhanden sein. Falls nötig

mit Getriebeöl EP90 nachfüllen.

**

**

* Das Getriebeöl mindestens alle zwei Jahre wechseln. Die Quali-tät

des Getriebeöls immer überprüfen, wenn das Boot auf Land

liegt.

**

**

* Die Bolzen, die das Getriebegehäuse mit der Motorhalterung

verbinden, beim ersten Service an Land mit dem angegebe-nen

Anzugsmoment (s. Seite 14/15) entsprechen nachziehen.

**

**

* Vor jeder Saison auf Propeller und Getriebegehäuse Antifouling

aufbringen.

PS ! Zinkanode, Dichtungen und Propellerachse frei von

Antifouling halten. Die Aussparungen im Getriebegehäuse

nicht mit Anti-Fouling "füllen", da hier die Propellernabe

läuft.

**

**

* Die Zinkanode vor jeder Saison oder wenn diese zur Hälfte ab-

genutzt ist ersetzen. Zur Sicherung der Befestigungsschraube

der Zinkanode immer Locktite o.ä. verwenden. Bitte beachten

Sie, daß unter bestimmten Milieubedingungen eine zusätzliche

Zinkanode nötig sein kann, damit der Korrosionsschutz

gewährleistet ist, solange sich das Boot im Wasser befindet.

Hierzu kann Ihnen Ihr Händler nähere Informationen geben.

**

**

* Bei jedem Service und vor jeder Saison sollte folgendes

überprüft werden:

• Der Propeller ist sicher befestigt.

• Die Bolzen, die den Motor auf der Motorhalterung befestigen

sind korrekt angezogen.

• Die Umgebung des Thrusters ist sauber und trocken. Bei

Wassereinbruch, muß der Grund dafür beseitigt werden.

• Alle elektrischen Verbindungen sind sauber und fest.

• Sicherstellen, daß am Thruster ausreichend Spannung anliegt.

Alte oder mangelhafte Batterien reduzieren die Leistung und

sollten ausgetauscht werden.

Wartung

D

**

**

* All models except SH 100: There must always be oil in the oil

reservoir. Refill if necessary with gear oil EP90.

**

**

* All models except SH 100: Change the gear oil a minimum of

every second year. Check the gearoil quality in the gearhouse

every time the boat is out of the water.

**

**

* Retighten the bolts holding the gearhouse to the motorbracket

during the first on-land service with the specified bolt tightening

force (see page 14/15).

**

**

* Keep the propeller and gearhouse clean from growth by painting

with antifouling before every season.

PS ! The zinc anode, sealing and propeller shafts must

abso-lutely not be painted. Be careful that you don't fill

paint in the "tracks" in the gearhouse that the propeller hub

moves in.

**

**

* Change the zinc anode before every season, or when about half

the anode is gone. Always use a sealant on the screw holding

the zincanode to ensure that it does not fall off. Please observe

that in some waterconditions it can be necessary to install an

extra zincanode to ensure that it lasts for the whole period

between regular service lifts of the boat. Consult your dealer for

information on how to do this.

**

**

* As a part of the seasonal service of your boat, and before every

season, always check that:

• The propeller is securely fastened

• The bolts holding the electric motor to the motorbracket are

fastened correctly.

• The area where the thruster is installed is clean and dry. If there are

signs of water you must try to find the source and eliminate it.

• All electrical connections are clean and fastened firmly.

• Make sure that your batteries are in a good condition so that the

thruster gets a good voltage. Old or bad batteries will give a

reduced performance from the thruster.

Maintenance

GB

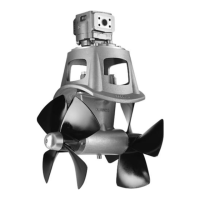

n Hydraulic motor

o Mounting plate

p Motorbracket for holding motor and

gearhouse together on the tunnel.

q Flexible coupling secures the

electromotor if propeller is jammed.

Changeable from inside the boat.

r Glassfibre reinforced lexan propeller

for ultimate performance.

s Oil-filled gearhouse. SH100: prefilled

t Changeable zincanode protects gear-

house from corrosion in seawater.

SH100/185 T - SP 220 HYD - SP 300 HYD

5

6

3

2

1

4

7

Locktite

SH100/185T - SP 220 HYD - SP 300 HYD - SP 550 HYD

2.4 - 2007

21

n

o

p

r

s

t

n Oil drain screw with washer

o Keys

p Washer

q Propeller lock nut

r Zinc anode

s Screw for zinc anode

SP 550 HYD

SP 100 HYD

SP 220 HYD / SP 300 HYD / SP 550 HYD

n Fastening screw for zincanode

o Zincanode

p Propeller lock nut

q Washer

r Drivepin for propeller

s Oil drain screw

t Copper washer/seal for oil drain screw

21

SE 80/185 T - SE 100/185 T - SE 130/250T 1.0.1- 2008

Vedlikehold

N

» Etterstram boltene som holder girhuset sammen med braketten ved

første på-land servicen med oppgitt moment (s. 26).

» Hold propellen og girhuset fritt for algevekst ved å påføre bunn-stoff

før hver sesong.

PS ! Sinkanoder, tetninger og propellaksel skal ikke påføres

bunnstoff, pass på så det ikke kommer bunnstoff i gjenge-

sporene til propellmutteren.

» Skift sinkanode før hver sesong, eller når ca. halvparten av sink-

anoden har tæret bort. Bruk Locktite eller lignende på skruen til

sinkanoden for at den ikke skal falle av. Ta i betraktning at under noen

vannforhold er det nødvendig å montere en ekstra sink-anode for å

være sikker på at de skal vare i hele perioden mellom vedlikehold. Ta

kontakt med din forhandler for informasjon om hvordan å gjøre dette.

» Som en del av det periodiske vedlikeholdet av din båt, og før hver

sesong må følgende ting sjekkes:

• Propellen sitter godt festet.

• Boltene som holder elektromotoren til braketten sitter.

• Skottet der baugpropellen er montert skal være rent, og tørt. Hvis det

er vann i skottet må lekkasjen nnes og tettes.

• Alle elektriske tilkoblingspunkter er rene, og godt festet.

• Pass på at Deres batterier er i god stand så det kan gi høy spenning til

thrusteren. Redusert spenning vil gi redusert effekt på thrusteren.

5

32

1

4

Locktite

Maintenance

GB

Electromotor

Directional solenoids

Motorbracket for holding motor and

gearhouse together on the tunnel.

Flexible coupling secures the electromo-

tor if propeller is jammed. Changeable

from inside the boat.

5-blade skew propeller for ultimate

performance.

Oil-lled gearhouse.

Changeable zincanode protects gear-

house from corrosion in seawater.

Fastening screw for zincanode

Zincanode

Propeller lock nut

Washer

Drivepin for propeller

7

4

5

6

1

3

2

4

5

1

3

2

1

7

3

4

6

» Retighten the bolts holding the gearhouse to the motor bracket

during the rst on-land service with the specied bolt tightening

force (see page 26).

» Keep the propeller and gearhouse clean from growth by painting

with antifouling before every season.

PS! The zinc anode, sealing and propeller shafts must absolutely

not be painted. Be careful that you don’t ll paint in the “tracks” in

the gearhouse that the propeller hub moves in.

» Change the zinc anode before every season, or when about half

the anode is gone. Always use a sealant on the screw holding the

zincanode to ensure that it does not fall off. Please observe that in

some waterconditions it can be necessary to install an extra

zincanode to ensure that it lasts for the whole period between

regular service lifts of the boat. Consult your dealer for information

on how to do this.

» As a part of the seasonal service of your boat, and before every

season, always check that:

• The propeller is securely fastened

• The bolts holding the electric motor to the motor bracket are

fastened correctly.

• The area where the thruster is installed is clean and dry. If there

are signs of water you must try to nd the source and eliminate it.

• All electrical connections are clean and fastened rmly.

• Make sure that your batteries are in a good condition so that the

thruster gets a good voltage. Old or bad batteries will give a

reduced performance from the thruster.

5

3

2

1

4

Locktite

5

2

12

SE 80/185 T - SE 100/185 T - SE 130/250T 1.0.1- 2008

Montering av propeller

N

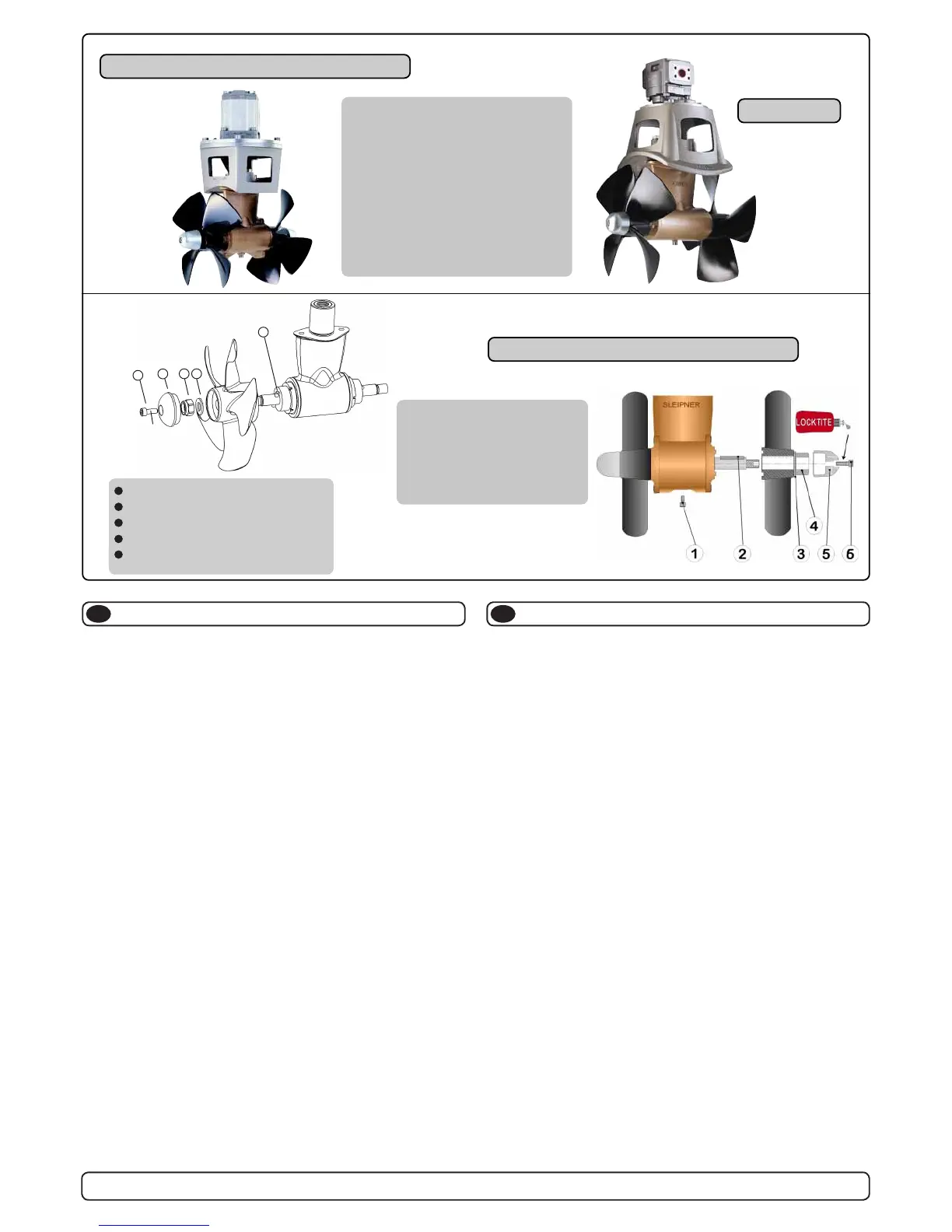

1. Vri propellakselen så drivpinnen (5) står loddrett. Pinnen må stå midt i

propellakselen.

2. Vri propellen så sporet for driv pinnen er loddrett, eller i lik vinkel som

du har stilt drivpinnen. Skyv propellen inn på propellakselen. Det skal

nesten ikke være klaring mellom propellen og girhuset.

3. Sett på skiven (4) på propellakselen, deretter strammes låsemutteren

(3).

4. Plasser sinkanoden (2) i sporet sitt. Fest den med skruen til sinkan-

oden (1). Bruk gjengelim (Locktite eller lignende) for at skruen ikke

skal skrus ut av propellrotasjonen.

Delebeskrivelse:

1: Skrue til sinkanode

2: Sinkanode

3: Låsemutter til propell

4: Skive til propell

5: Drivpinne for propell

5

3

2

1

4

Locktite

Fitting propeller(s)

GB

1. Push the propeller onto the shaft, carefully rotate the propeller

until the drive pin aligns and moves into the slot/grove in the

propeller hub. There should be almost no gap (approximately

1mm) between the propeller hub and the gear house.

2. Place the washer (4) on the propeller shaft and then tighten the

lock-nut (3) on the propeller shaft.

3. Place the zinkanode (2) in its designated position and tighten the

zincanodes holding screw (1). Apply a thread glue (Locktite or

similar) to ensure that the zincanodes holding screw does not un-

screw itself from the propellers rotation.

Parts description:

1: Screw for zincanode

2: Zincanode

3: Propeller lock nut

4: Washer

5: Drive pin for propeller

Loading...

Loading...