Connection

6.1 Electrical connection

WOGeneric TEAAC / 2008

28 Siemens AG Operating Instructions 1.03 1RQ671...-Z

Components provided by customer

You, the customer, provide the following components:

● Cable lug and component parts

● Cable glands

● Cable

● Parts for connection to equipment already on-site

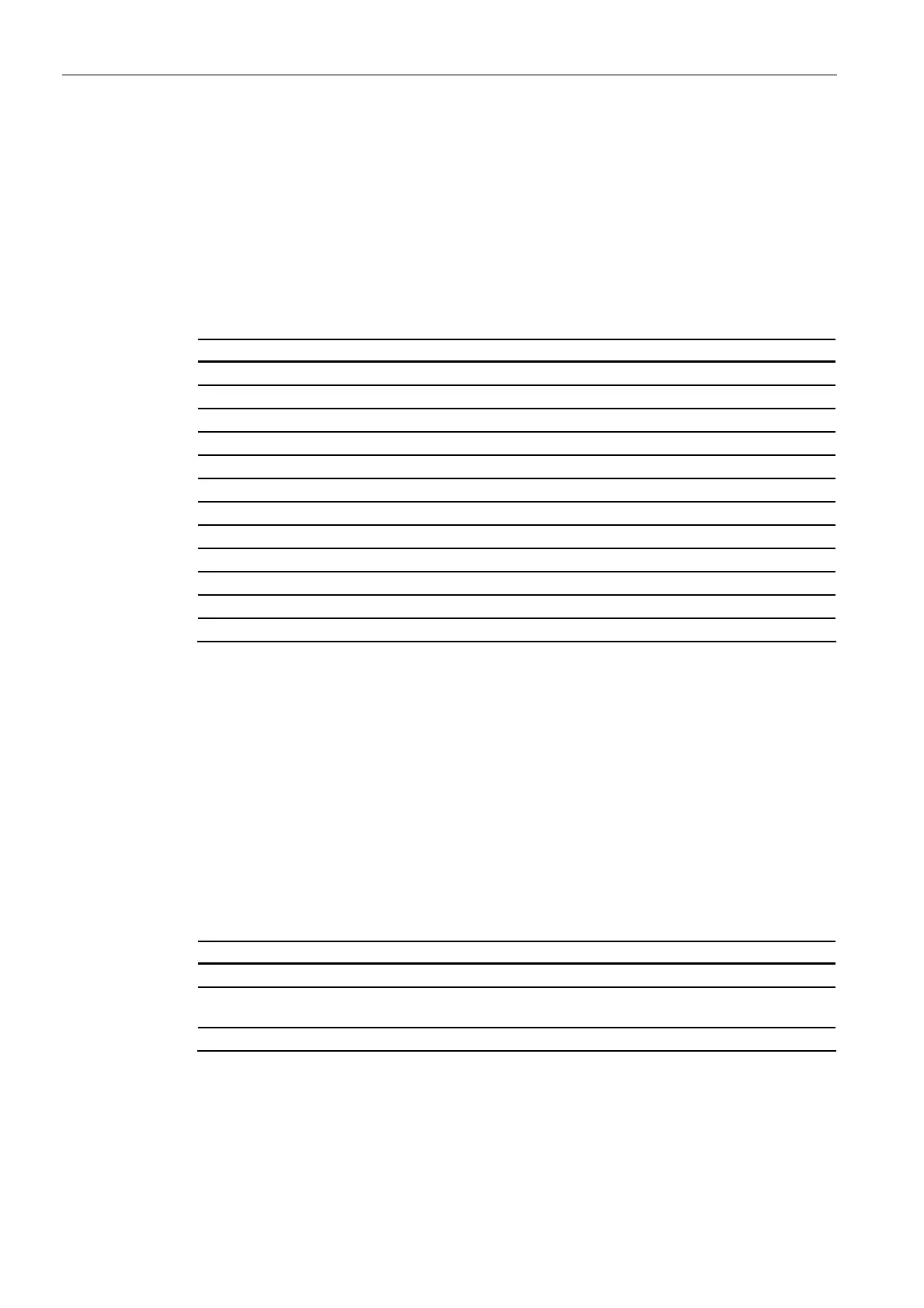

Table 6-5 Parts for connection to equipment already on-site

Part number Description

22.92.1 Hexagon bolt ISO 4017-M12x50-8.8

22.92.2 Hexagon bolt ISO 4017 M16X50-8.8

22.92.3 Washer ISO 7089-12-200HV-A2

22.92.4 Washer ISO 7089-16-200HV-A2

22.92.5 Washer ISO 7093-1-12-200HV-A2

22.92.6 Washer ISO 7093-1-16-200HV-A2

22.92.7 Conical spring washer DIN 6796-12-FST-MECH.ZN12C

22.92.8 Conical spring washer DIN 6796-16-FST-MECH.ZN12C

22.92.9 Spring washer DIN 128-A12-FST-A3L

22.92.10 Spring washer DIN 128-A16-FST-A3L

22.92.11 Hexagonal nut ISO 4032-M12-8.8

22.92.12 Hexagonal nut ISO 4032-M16-8

Selecting the cables

● When choosing connecting cables, you must take into account the rated current, possibly

the service factor, and the plant-specific conditions (e.g.ambient temperature, routing

type, etc. to IEC/EN 60204-1).

Connecting using cable lugs

Connection with cable lugs is only permitted for conductor cross-sections ≥ 70 mm2 to

300mm², to prevent the cable lugs twisting on connection.

● Select the cable lugs according to the required cable cross-section and screw size.

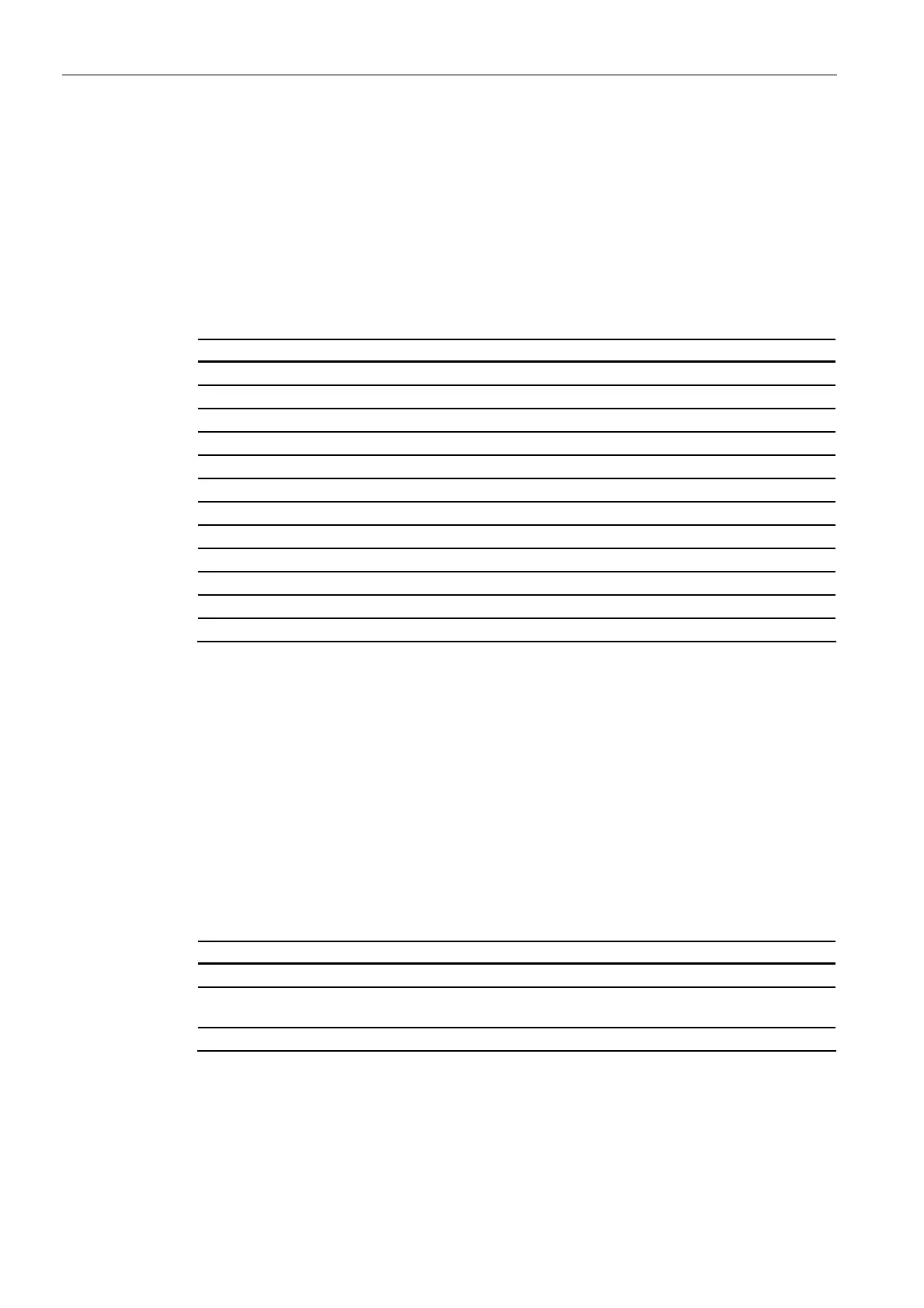

Table 6-6

Technical specifications for selecting the cable lug

IEC NEMA

Screw size M16 M12

Max. cable cross section and max. number per

phase

6 x 300 mm

2

AWG 600 kcmil

Max. size of the cable lug DIN 46235 16-300 Burndy YA36 2N

Loading...

Loading...