Do you have a question about the Siemens MJ-5 and is the answer not in the manual?

Outlines the manual's purpose and structure to help users understand the MJ-5 Control Panel.

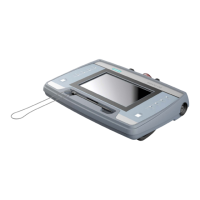

Details standard MJ-5 Control Panel features including display, metering, data logging, and various control functions.

Covers the front panel layout, display screen, and methods for navigating data using menu and fast-path keys.

Details various operational controls like keys, switches, indicators, ports, fuses, and binding posts.

Explains the Power Switch, Auto/Off/Manual switch, and Remote/Local settings for controlling the panel.

Describes binding posts and terminal strip connections for external devices and control panel wiring.

Details the purpose and rating of the MJ-5 Control Panel's internal and external power fuses.

Describes terminal strip connections for various control functions and current transformer routing.

Explains the use of USB and SD card ports for data transfer, configuration, and communication.

Describes two methods for viewing data: using menu selection keys and fast-path keys.

Explains how MJ-5 data is organized into menus and data items, divided into setup and operational categories.

Details the steps to change configuration parameters and alpha/numeric settings using panel keys.

Explains how fast-path keys can be used as shortcuts to view and change frequently used data items.

Outlines the MJ-5 Control Panel setup process, including configuration, set points, logging, security, and communication.

Explains how to define regulator parameters and system settings using the CONFIGURE and ADV CONFIGURE menus.

Provides detailed descriptions of data items found within the MJ-5's Advanced Configuration menu.

Explains how to identify and configure the regulator type (ANSI Type A or B) and its characteristics.

Details configuration for Delta or Wye-connected systems, including wiring arrangements and polarity.

Describes settings for tap changer type, regulator type, system configuration, and transformer voltage ratios.

Details settings for power flow modes, current transformer ratio, and full load current specifications.

Explains how to set the real-time clock, date format, and daylight savings time for the MJ-5 Control Panel.

Details the Sliding Window and Thermal averaging methods used for accumulating demand values.

Explains how to set utility polarity and configure U2 and P2 potential transformer ratios for accurate voltage scaling.

Details settings for Delta Power, Power Flow Modes, and Current Transformer ratios for system analysis.

Describes different power flow modes (Forward Locked, Reverse Locked, etc.) and their operational implications.

Details how to set current transformer ratio and full load current for accurate system monitoring and protection.

Explains settings for meter voltage scaling, low current thresholds for tap change inhibition, and current shift.

Covers settings for time, maximum load current, and potential transformer thresholds for tap change control.

Details settings for demand calculation methods, min/max data timeouts, and screen timeouts.

Explains configuration for the Quick List feature and the AutoVari-Amp capability for tap position adjustments.

Configures tap limits, enables/disables tap alerts, and sets tap resynchronization behavior for improved operation.

Covers settings for communication auto-inhibit, lower LED behavior, and P2 calculation options.

Defines operating limits for automatic mode, including voltage level and bandwidth set points for forward and reverse power flow.

Explains how to set line drop compensation values to account for voltage drop between the regulator and the load center.

Details VRC settings, modes (Local, Remote, Auto), and how to configure VRC activation via terminal contacts.

Explains the ALT Delay feature and how to view the current VRC status, including reduction percentage and mode.

Describes the VRC modes: OFF (disables function), LOCAL (immediate reduction), and REMOTE (contact-activated reduction).

Explains automatic VRC operation based on load current and how remote override or terminal contacts can influence it.

Details how to activate VLC and set upper and lower voltage limits to prevent tap changes outside defined ranges.

Explains how to configure Event and Interval logging requirements, including enabling logging and defining data capture.

Describes how to view Event and Interval logs, and procedures for clearing log data from the panel.

Introduces the MJ-5 password protection system, including System Key and Level 1/Level 2 security.

Details the hierarchical password system (System Key, Level 1, Level 2) for controlling access to settings and changes.

Explains the purposes of the PASSWORD menu: entering passwords, defining passwords, and managing security system state.

Guides users on entering and changing the System Key, which controls security system configuration and access.

Provides instructions for changing Level 1 and Level 2 passwords and enabling password checking for enhanced security.

Details configuration of the Local Data Port, including baud rate, parity, addressing, and regulator identification.

Briefly mentions the Communications Module's role in remote communications and refers to its installation manual.

Explains how to view tap changer contact statuses (Excellent, Good, Worn, Replace) and operations counters.

Describes the algorithm that approximates wear and tear on tap changer contacts and how to enable/disable it.

Lists diagnostic items for calibration, including voltage, current, and timing parameters for tap changer operation.

Details parameters related to tap tracking, such as R/L OnTime, R/L OffTime, TapIn, and Neutral signal inputs.

Explains how to customize the Quick List by adding frequently accessed menu items or removing existing ones.

Defines "Source" and "Load" for power flow analysis and explains how U2 and P2 terminals relate to these definitions.

Describes the P2 Calc feature that calculates P2 voltage when a measured value is unavailable, requiring tap position data.

Details meter data items like voltage, current, power, and power factor, including instantaneous, max, and min values.

Explains how to view meter data items and their min/max values, including time and date stamps.

Details the meaning of power factor (leading/lagging) and apparent power (kVA) calculations as displayed by the MJ-5.

Describes demand data, which are time integration functions of metered values, maintained separately for forward and reverse power flow.

Explains how the MJ-5 records meter data at the time of specific events, such as power up or tap changes.

Describes how the MJ-5 records data at specific time intervals, logging values for voltage, current, power, and tap position.

Explains how to clear Event and Interval logs and reset min/max values at the start of each interval.

Details operation counter data for tap changer steps and explains the dead reckoning procedure for tracking tap position.

Explains how MJ-5 alerts represent exception conditions and how to view and interpret alert messages and indicators.

Describes the procedure to acknowledge an alert using the Cancel/Reset key, and the effect on the alert indicator.

Details how harmonics data for voltage and current are calculated and presented, including THD and harmonic components.

Explains how VRC Status indicates the current level of Voltage Reduction Control, including percentage and mode.

Describes the four operating modes: local manual, local automatic, remote control, and Off, selected via the Auto/Manual switch.

Provides a summary table comparing the behavior of MJ-5 control modes under different switch and LED configurations.

Details how the automatic control algorithm maintains output voltage within limits and the hierarchy for resolving conflicts.

Lists the factors the control algorithm considers, such as voltage, set points, LDC, VRC, current, and power flow.

Explains how the control program senses regulator output voltage and performs software scaling for accurate readings.

Details how VLC monitors output voltage against set points, inhibiting tap changes and returning voltage within limits.

Explains how the MJ-5 senses and adjusts operation for power flow reversals, alternating between Forward and Reverse modes.

Describes the Current Bias feature, active in Bi-Directional mode, and how Bias Percent affects tap changes based on current magnitude.

Details F LOCK (inhibits tap changes under reverse flow) and R LOCK (inhibits tap changes under forward flow) modes.

Explains Bi-DIR (regulation in both directions) and IDLE R (regulator idles at last tap position during reverse flow) modes.

Describes NEUT R mode, where reverse flow causes the tap changer to return to neutral position without stopping.

Explains CO-GEN mode for systems with consumer-generated power, using specific LDC values for forward and reverse flow.

Introduces MJXplorer and DNP Configure software for configuration, data download, and custom DNP point definition.

Outlines basic troubleshooting procedures, focusing on identifying fault location and user-correctable issues.

Explains how alert messages from the <ALERTS> menu can help diagnose system and internal MJ-5 problems.

Lists checks for external source fuse, fuse connectors, jumpers, and terminal strip connections for proper installation.

Details how to check the U2 and P2 voltage calibration against applied voltage using a voltmeter.

Provides step-by-step instructions to calibrate the U2 voltage reading on the MJ-5 panel using an external voltmeter.

Details the procedure for calibrating the load current (C/C2) reading using an external ammeter and current source.

Lists operating requirements for temperature, humidity, voltage range, and frequency for the MJ-5 Control Panel.

States metering accuracy and describes the MJ-5's immunity to electrical transients and RFI.

Details recommended switch settings for installation and explains the function of the Polarized Disconnect Switch (PDS).

Provides guidance and notes for replacing older control units with the MJ-5 Control Panel, including specific panel types.

Presents a schematic diagram illustrating the control connections for an ANSI Type 'A' (Straight) regulator.

Shows the wiring schematic for the regulator control panel, detailing terminal connections and internal circuitry.

Presents a schematic diagram illustrating the control connections for an ANSI Type 'B' (Inverted) regulator.

Explains how to determine leading/lagging regulators in Delta configurations and set initial parameters.

Details the process for calculating and setting line drop compensation values using the "Load Center" method.

Guides on determining and setting transformer polarity (NORM or REV) based on regulator nameplate schematics.

Details how to set polarity for single-phase straight design regulators based on tap position relative to E2.

Details how to set polarity for single-phase straight design regulators based on tap position relative to E2.

Explains polarity settings for regulators with forced air cooling, referencing nameplate schematics and connection tables.

Discusses three-phase regulators with single utility windings and how to determine polarity based on connections.

Explains how to configure multiple utility windings for control, motor, and fan power based on phase winding usage.

Warns about the critical importance of neutral position for bypassing, highlighting risks of catastrophic failure from circulating current.

Provides mandatory steps to completely disable the control panel before bypassing operations to prevent inadvertent tap operations.

States that the MJ-5 Communications Module mounts directly to the Main Processor board and refers to the installation manual.

Provides a quick reference to the MJ-5 menu structure, listing data items across Meter, Demand, Counters, Regulator, Configure, etc.

Guides on viewing and setting voltage level and bandwidth values using fast-path keys and menu navigation.

Details procedures for viewing and setting time delay values and line drop compensation components (resistance/reactance).

Explains how to view operation counters, active alerts, and acknowledge alerts using panel keys.

Guides on configuring the control panel, including menu navigation, changing values, and setting the clock/date.

Describes the connections for terminal strip TB1B, detailing signal names, descriptions, and I/O power for various functions.

Details connections for terminal strips TB2A (VRC, input pairs) and TB2B (output relays), outlining their functions.

Provides instructions for fine-tuning tap tracking by adjusting settings like R/L OnTime and TapInPulse.

Guides on using a voltmeter for U2/P2 calibration and setting the tap position using the <COUNTERS> menu.

Provides step-by-step instructions for safely removing the existing Cooper control panel from the regulator.

Details the process of installing the MJ-5 control panel onto a CL-6 Cooper voltage regulator, including wiring and connection.

Guides on removing the GE SM3 control panel, including disconnecting plugs, circuit boards, and wiring.

Details the installation of the MJ-5 control panel onto a GE regulator with an SM3 control panel, including mounting and wiring.

Provides instructions for removing the GE control panel, including disconnecting plugs, wires, and circuit boards.

Details the installation of the MJ-5 control panel onto a GE Type VR-1 regulator, including wiring harness connections.

Explains the tap tracking algorithm, sensing operations, and potential issues like lost tap position or incorrect direction.

Identifies common tap track errors ("Tap Pos ???", "Tap Track Err") and their possible causes and initial correction steps.

Explains configuration options for tap changer type, neutral signal input, and neutral count for different regulator manufacturers.

Details synchronization methods (Siemens, GE, Cooper, LTC) and active diagnostic parameters influencing tap tracking.

Describes the new tap control algorithm's intent for robustness and universality, and its configurable parameters in the Diagnostics menu.

| Brand | Siemens |

|---|---|

| Model | MJ-5 |

| Category | Control Panel |

| Language | English |