English

Additional Equipment Manual EEx p E-9

Order No.:

A5E 000 58873-02

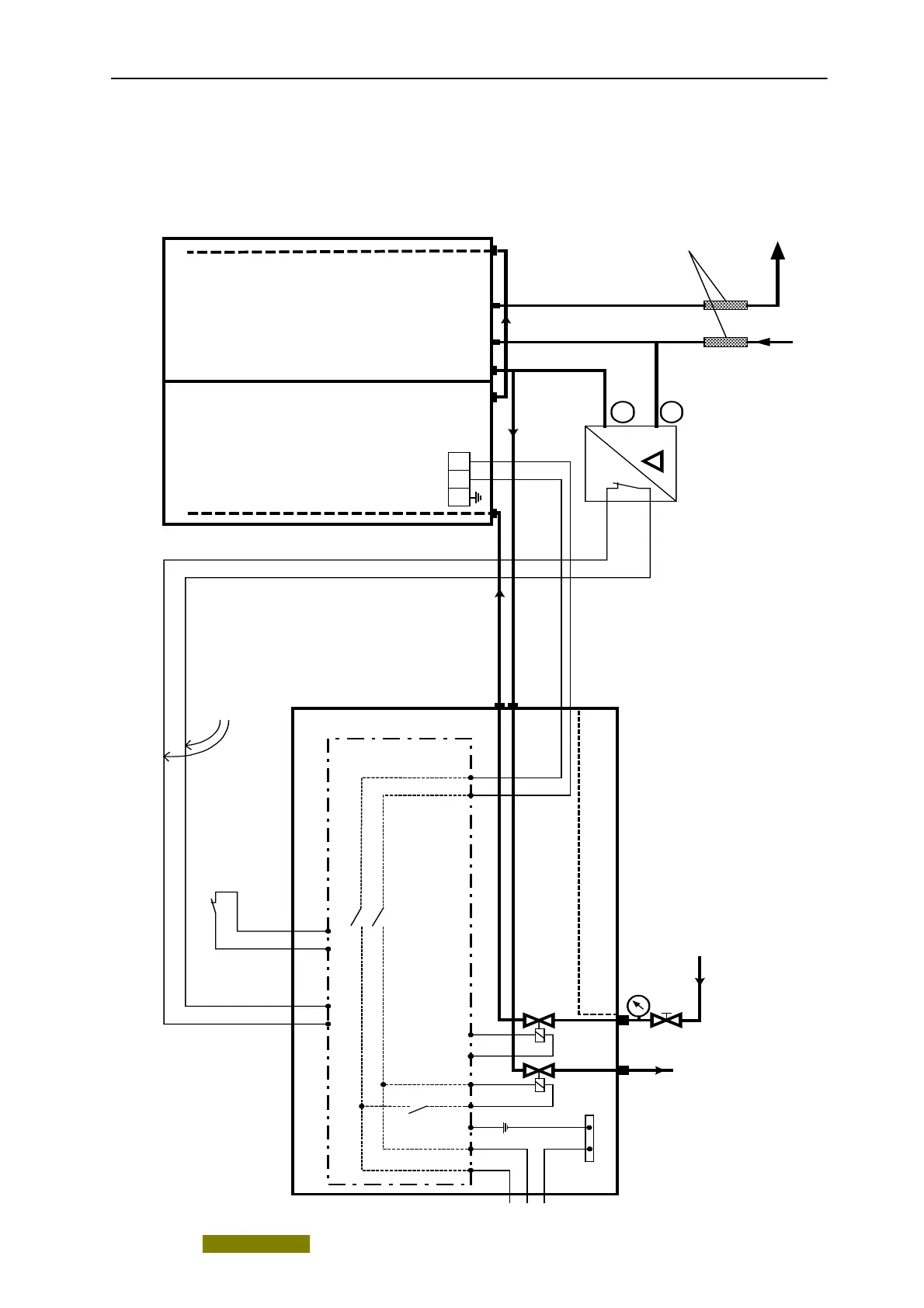

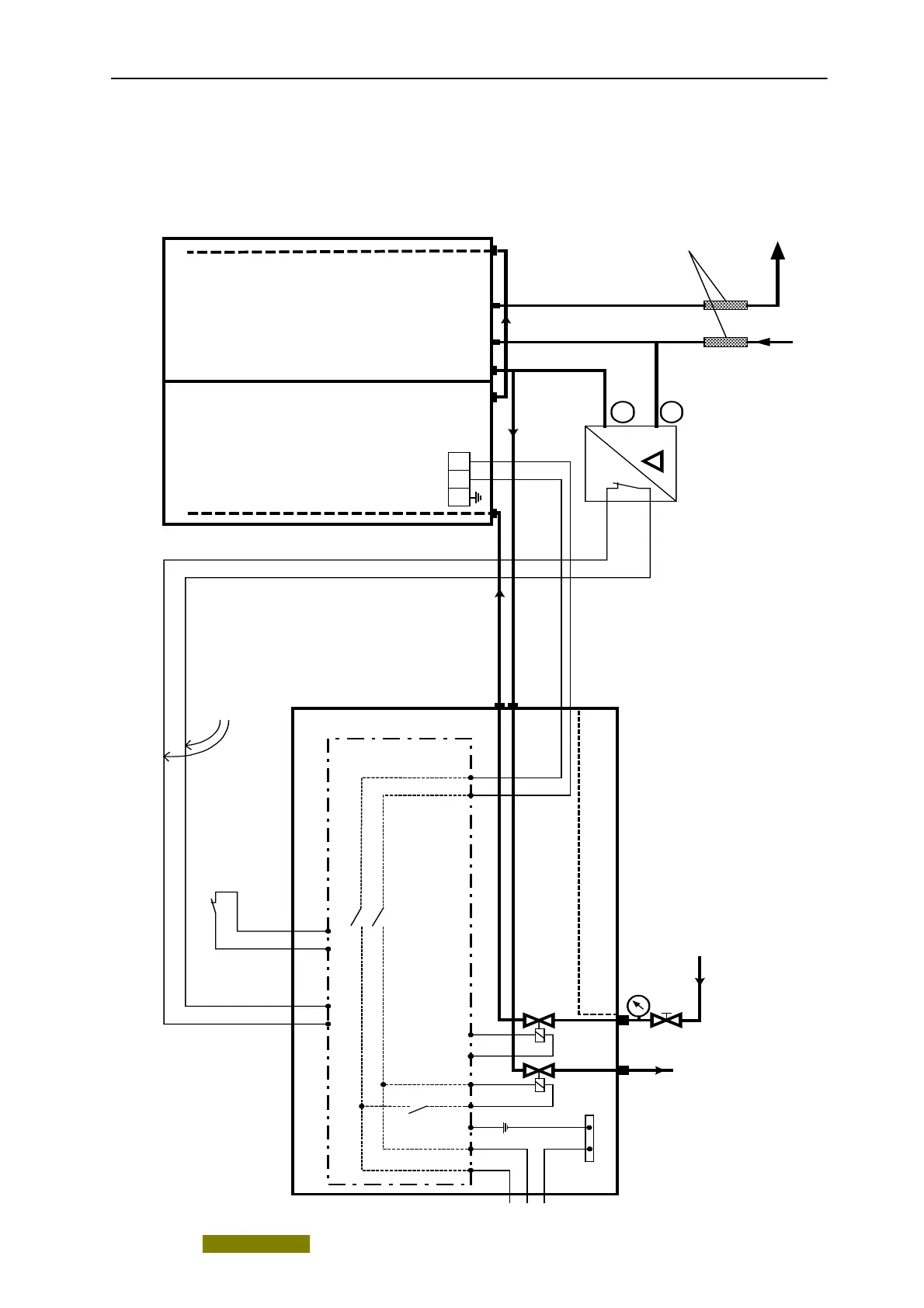

3.2 Assembly diagram for the versions EEx p with "Compensation of losses

resulting from leaks"

PE L

N

Power supply

connection

Outlet

valve

Inlet valve

p

EEx p purging gas monitoring device

L1

N

PE

Outlet of

purging gas

into Ex-free

zone

-

Sample

gas inlet

Sample

gas outlet

Intrinsically-safe

scanning of

pressure switch

Inlet of protective gas

(purging gas)

input pressure: 0,2...0,4 MPa

CALOMAT 6F

OXYMAT 6F

ULTRAMAT 6F

Control electronics

Purging gas

pipelines:

max. 4 m long;

diameter > 8 mm

*

)

*) With resistor for monitoring line breakages if applicable (see Instruction Manual of EEx p purging gas

monitoring device). If the sample gas cannot be applied with operational reliability, a second differential

pressure switch must be connected whose contact must be connected in series with the first switch.

With certain suppliers of EEx p purging gas monitoring devices, a relative pressure sensor can also be

connected instead of the differential pressure switch.

Gas connections:

C 6F and O 6F: 2 and 4

U 6F (SG): 1 and 2

U 6F (RG): 3 and 4

(see also associated

manual)

5

6

7

8

Flame inhibitors

Differential

pressure

switch

V1

Key switch

(only with

occasionally

combustible

gas

mixtures)

+

Loading...

Loading...