Fail-Safe Modules

7.6 EM 4 F-DI/3 F-DO DC24V PROFIsafe digital electronic module

ET 200S Distributed I/O System - Fail-Safe Modules

158 Installation and Operating Manual, 08/2008, A5E00103686-07

Causes of Faults and Corrective Measures

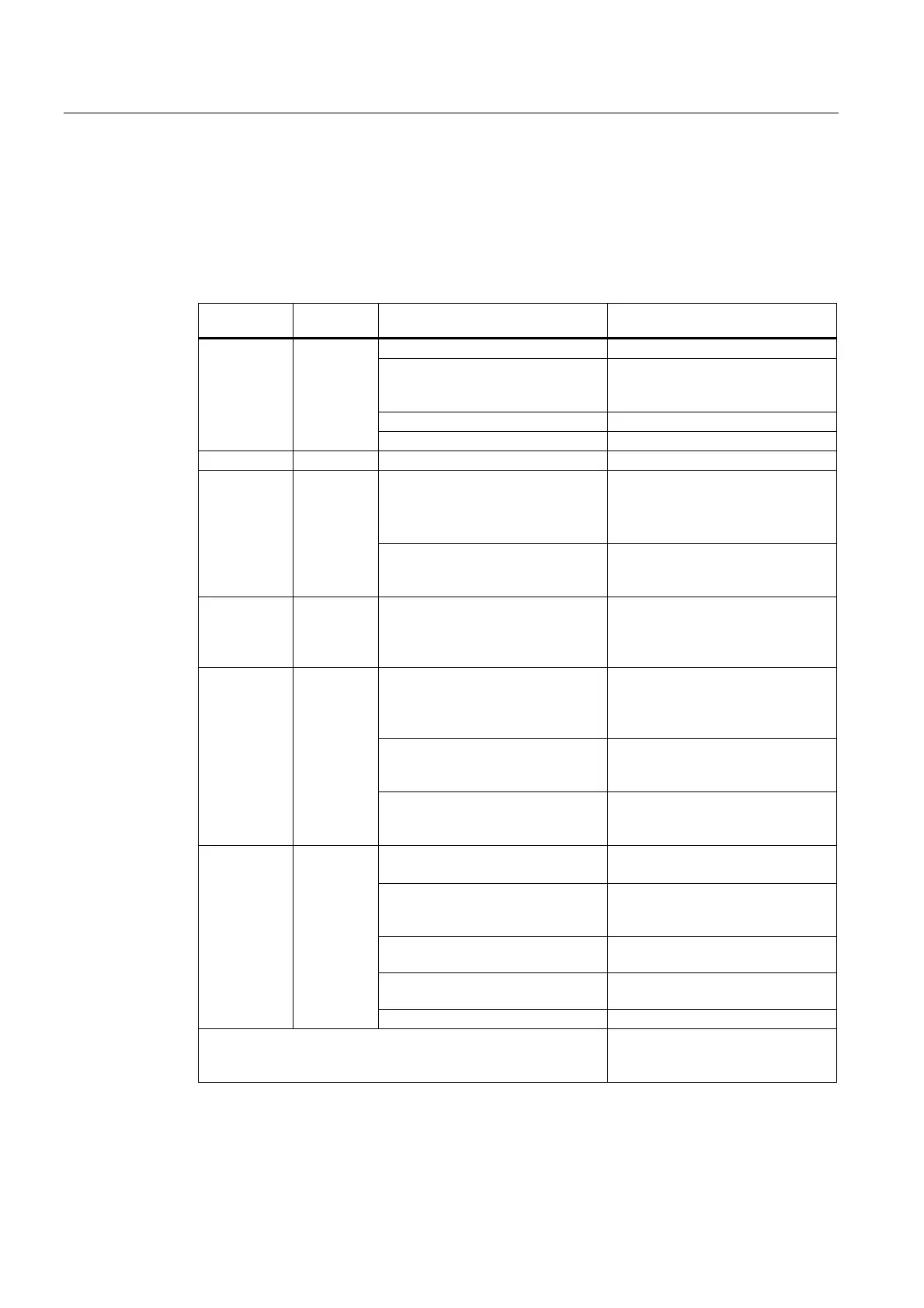

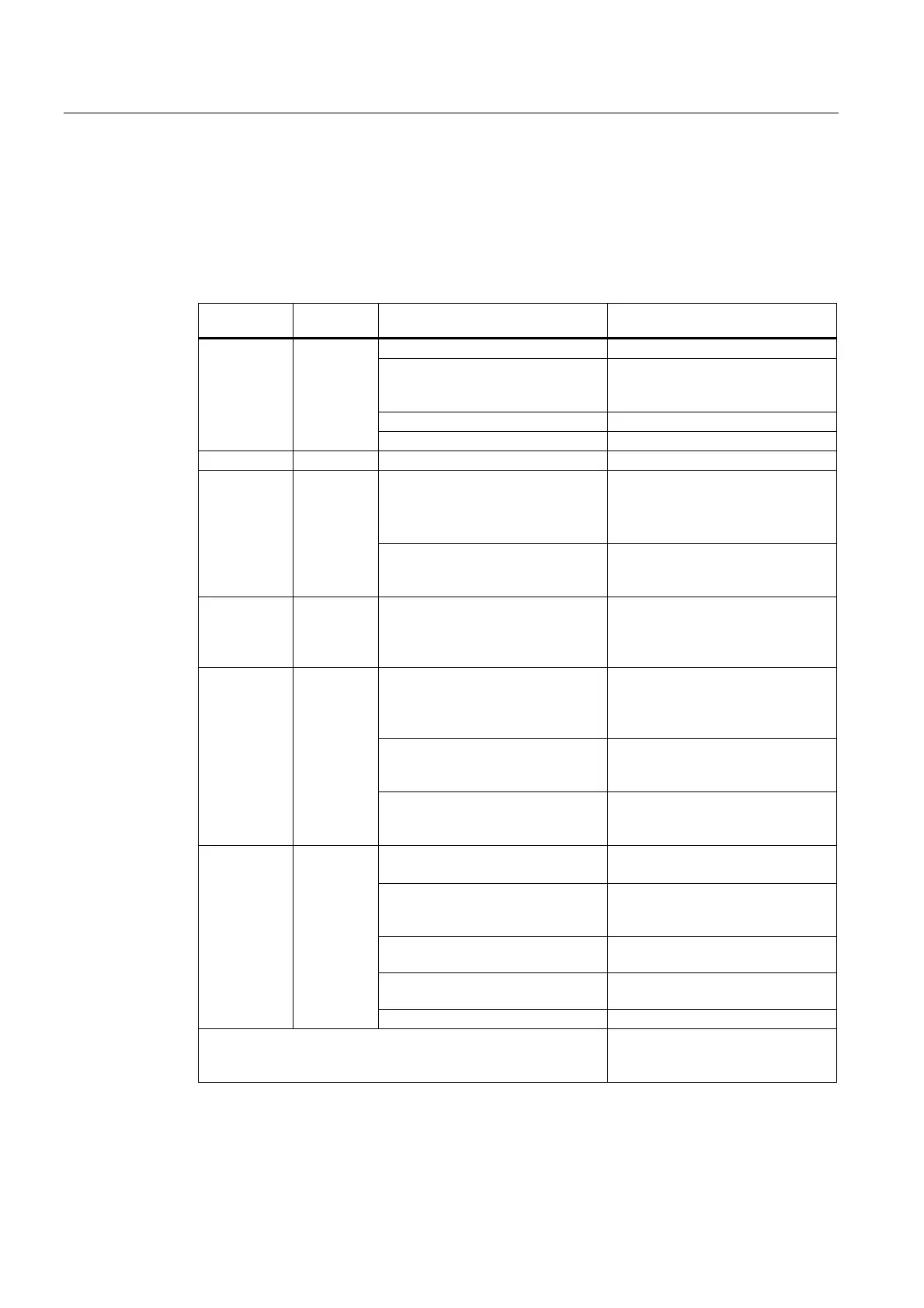

The following table contains the possible causes of the faults described for the individual

diagnostic messages of the EM 4 F-DI/3 F-DO DC24V PROFIsafe and remedies.

Table 7- 33 Diagnostic messages of the EM 4 F-DI/3 F-DO DC24V PROFIsafe, causes of errors and

remedies

Diagnostic

Message

Fault

detection

Possible Causes Corrective Measures

Short circuit in the sensor/actuator Eliminate the short-circuit.

Cross-circuit at the sensor/actuator Eliminate the cross-circuit within

100 hours after the error has

occurred.

Encoder supply short circuit Eliminate the short-circuit.

Short-circuit Depends

on

parameter

settings

Internal error Replace module

Internal error Always Internal module fault has occurred Replace module

Inserted module does not match

configuration

Faulty parameter assignment

Correct configuration (compare

actual and preset configuration)

Check communication paths

Correct configuration

Parameter

assignment

error

Always

PROFIsafe address set incorrectly

in the F-module

Check whether the PROFIsafe

address on the module matches

the configuration in

HW Config

Sensor

voltage or

load voltage

missing

Always No supply voltage or supply

voltage is too low

Check the supply voltage on the

interconnected PM,

Check module for correct contact

Error in communication between F-

CPU and module due to defective

PROFIBUS connection or higher

than permissible EMI, for example

Check the PROFIBUS/PROFINET

connection

Eliminate the interference

PROFIsafe monitoring time set too

low

Set a greater value for the "F

monitoring time" parameter for the

module in

HW Config

Communicati

on error

Always

Configuration of the F-module

does not match safety program

Generate safety program again;

then load configuration and safety

program into F-CPU again

Faulty process signal

Defective sensor

Check process signal, replace

sensor if necessary

Short circuit between unconnected

sensor cable and the sensor

supply cable

Eliminate short circuit

Wire break in connected sensor

cable or the sensor supply cable

Eliminate broken wire

Assigned discrepancy time too

short

Check the assigned discrepancy

time

Safety-

related

shutdown

Always

Switching frequency exceeded Reduce the switching frequency

Once the fault is eliminated, the F-

module must be reintegrated in the

safety program

Detailed information on F I/O access can be found under

"Diagnostics"

in the

S7 Distributed

Safety, Configuring and Programming

manual or the

S7 F/FH Systems, Configuring and

Programming

manual.

Loading...

Loading...