Differential Pressure Switch

Adjusting the Differential Pressure Switch

Adjust the PolyBlend differential pressure switch only if pressure

and flow

to the system

are adequate

.

The adjustment logic is the

opposite

of what you might expect.

The

PolyBlend differential pressure switches have a red light (on the left side)

that lights up whenever source water flow is too low and the polymer

pump is disabled. The pump stops pumping when the flow is too low.

Low flow may be from lack of incoming water or from too much back

pressure on the outgoing side.

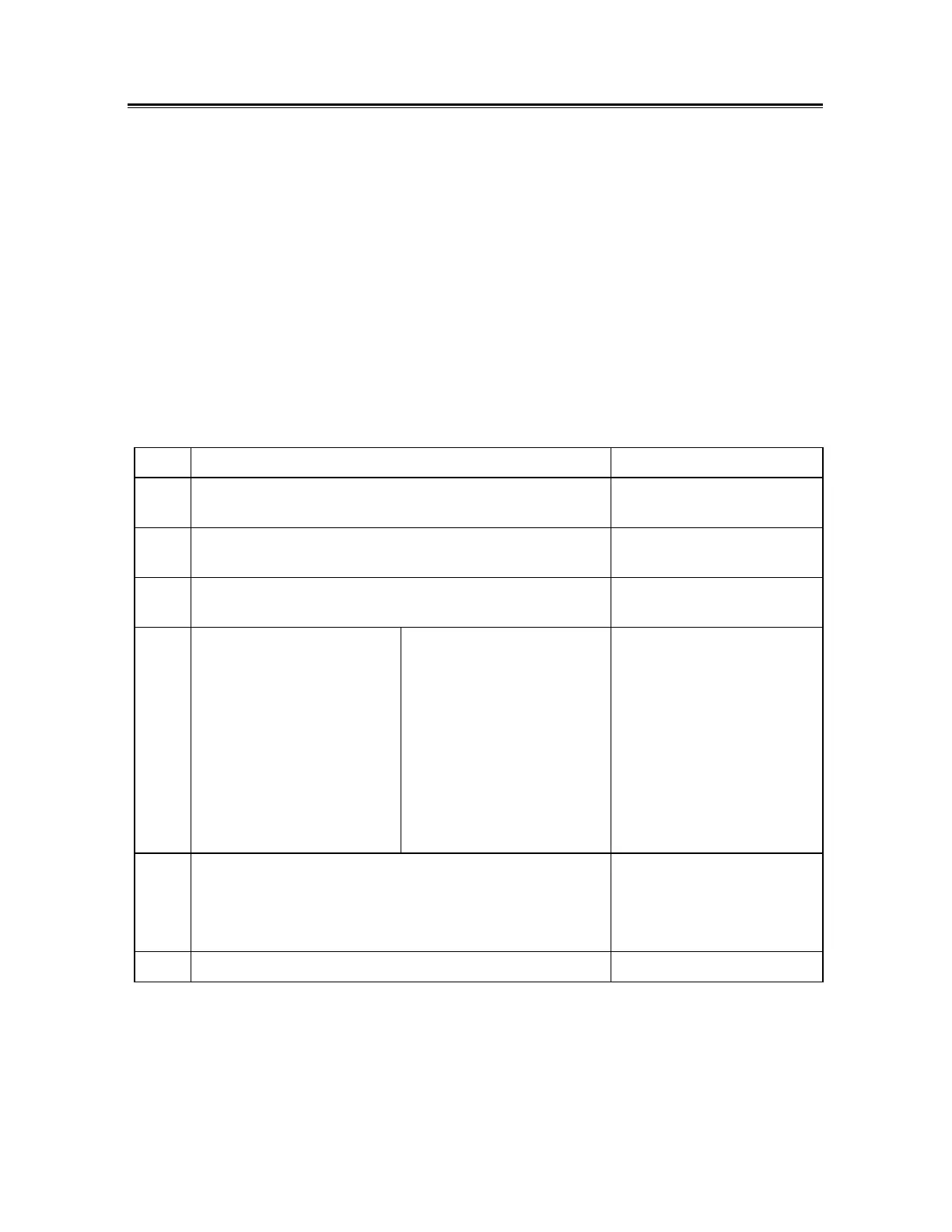

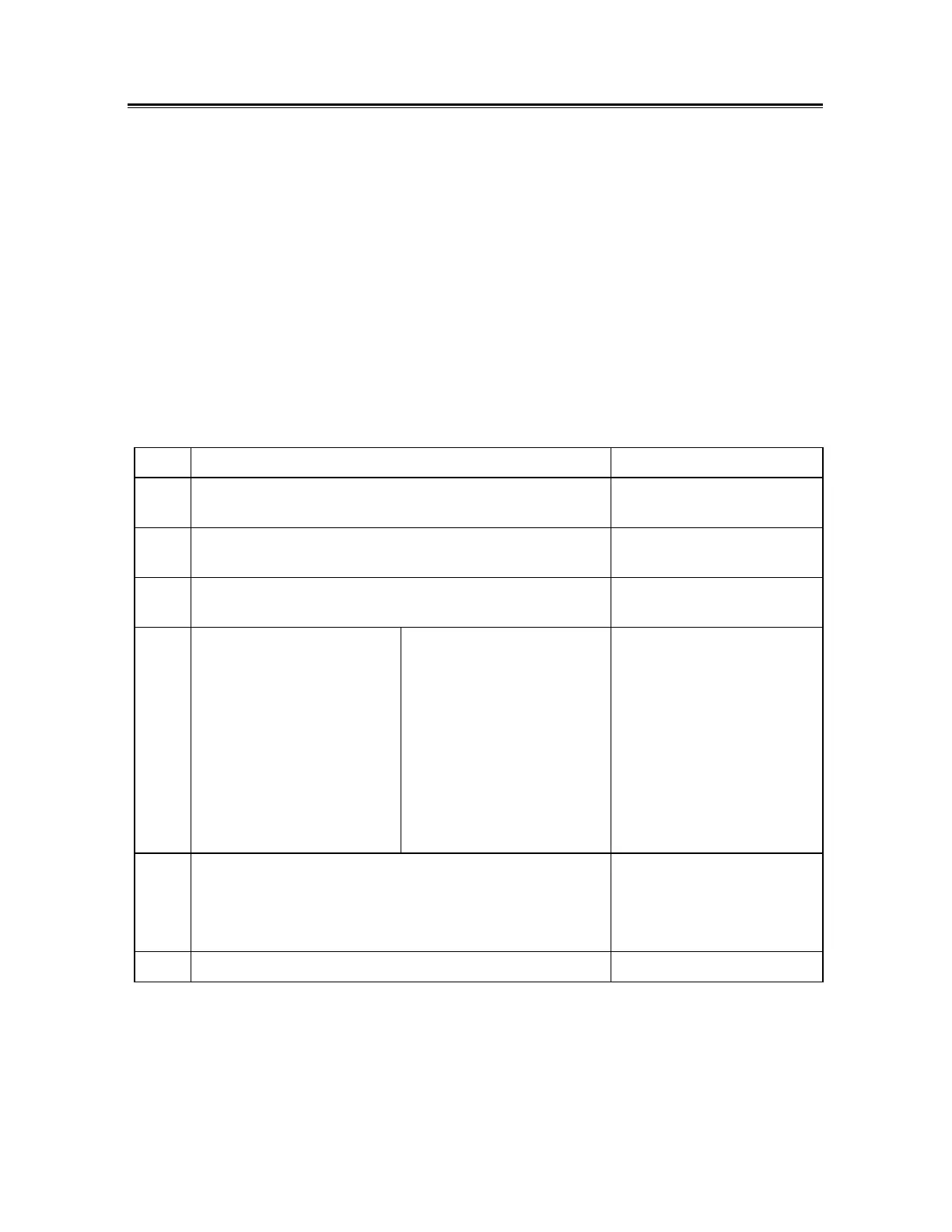

Adjustment

System Reaction

1.

Turn the PolyBlend rotameter until water flow is at

maximum

on the flow gauge.

2. Screw in the differential pressure knob until the red

alarm

light goes on.

Polymer pump is

disabled.

3.

Back off the differential pressure knob until the red alarm

light goes off.

The pump starts again. ......

4.

4a.

If you want very close

control of flow, leave the

knob at this setting.

At this setting, any loss of

flow (as observed by the

rotameter) results in the

pump being disabled.

4b.

If you want to make the

system "more forgiving"

prior to shutdown,

continue

to turn the knob

another

1-2 turns.

The further you turn the

knob, the more How can be

lost before the pump is

disabled.

Step 4 determines how

"forgiving" the system is

before it shuts down due

to

inadequate flow.

5.

To test sensitivity and operation, turn off the water at the

source or the solution at the discharge.

The float in the flow meter will fall more for the control

knob

setting described in step 41) than, for 4a (above).

As the source or discharge

is turned off, the float in the

flow meter falls and the

pump is

disabled.

6.

Set the rotameter for the desired flow.

Retest (as in step 5).

Loading...

Loading...