Do you have a question about the Siemens SIMATIC IM151-1 and is the answer not in the manual?

Explains the manual's goal, supplementing other documents for commissioning.

Outlines necessary prior knowledge for understanding the manual.

Defines the manual's applicability and content validity period.

Advises on environmentally compliant disposal of electronic waste.

Provides contact information and portal links for further assistance.

Details the features of the IM151-1 HIGH FEATURE interface module.

Lists limitations and incompatible modules for the IM151-1 HIGH FEATURE.

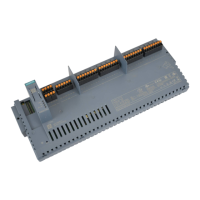

Shows the terminal connections for the interface module.

Illustrates the internal structure and connections of the interface module.

Provides key technical specifications like dimensions, voltage, and current.

Explains the meaning of LEDs and diagnostic functions.

Guides on how to update the module's firmware using STEP 7.

Discusses using more than 244 bytes of parameter data with specific STEP 7 versions.

Lists and describes configurable parameters for the interface module.

Explains individual parameters like DP interrupt mode, bus length, and option handling.

Achieving reproducible response times using cycle synchronization.

Covers principles, requirements, and optimization for synchronous operation.

Provides tips for achieving shorter constant bus cycle times.

Recommends HIGH FEATURE modules for isochronous structures.

Explains how overlapping Ti and To reduces system reaction time.

Lists requirements for achieving a constant bus cycle time of 0.5 ms or more.

Details the step-by-step configuration of cycle synchronization.

Lists common issues and their solutions during isochronous operation.

Explains how to use RESERVE modules for future expansion or flexibility.

Describes how option handling with RESERVE modules checks slot configurations.

Lists requirements for implementing option handling with RESERVE modules.

Illustrates configuration variants for using RESERVE modules.

Details how to assign parameters for option handling with RESERVE modules.

Using PIQ/PII to control and monitor RESERVE module configurations.

Provides solutions for common errors in option handling with RESERVE modules.

Maps PIQ/PII addresses for option handling and status bytes.

Configuring the system without using RESERVE modules.

Describes how the IM151-1 operates without RESERVE modules.

Lists requirements for configuring option handling without RESERVE modules.

Illustrates an example of using option handling without RESERVE modules.

Details the steps to configure option handling without RESERVE modules.

Describes IM151-1 behavior during initial power-up without RESERVE modules.

Explains IM151-1 behavior after a warm restart without RESERVE modules.

Guides on controlling and monitoring options without RESERVE modules using PIQ/PII.

Explains how to access and interpret module identification data.

Outlines steps to start testing options and ensure data consistency.

Explains how to access specific identification data via data records.

Illustrates the LED indicators on the interface module and their meanings.

Details the combined status and error displays of the SF, BF, and ON LEDs.

Explains how diagnostic messages are handled in DPV0 and DPV1 modes.

Describes how errors are reported in DPV0 mode via diagnostics frame and SF LED.

Explains diagnostic interrupts, CPU actions, and SF LED behavior in DPV1 mode.

Covers methods for reading out diagnostics using STEP 7.

Details how to read slave diagnostics using STEP 7 functions and tabs.

Breaks down the slave diagnostics frame structure, including status and specific diagnostics.

Explains the meaning of bits in station status bytes 0, 1, and 2.

Identifies the byte containing the master's PROFIBUS address in diagnostics.

Describes how module errors are indicated via identifier-related diagnostics.

Details the module status codes indicating module health and validity.

Explains how channel-specific errors are reported and structured.

Describes the H status in the diagnostic frame for Y-link configurations.

Defines the interrupt section and data records for interrupt information.

Details the structure of the interrupt section in the diagnostic frame.

Explains the content of bytes x+4 to x+7 for diagnostic interrupts.

Details channel type, length, and events for diagnostic interrupts.

Lists error types for channels 0 to 3 in diagnostic interrupts.

Provides a step-by-step example of interpreting a diagnostic interrupt.

Shows structure of bytes for process interrupts from digital input modules.

Shows structure of bytes for process interrupts from analog input modules.

Lists invalid configurations leading to station failure and their diagnostics.

Lists interrupt types supported in DPV1 mode for ET 200S.

Explains how events trigger diagnostic interrupts and OB 82 processing.

Details how STEP 7 processes process interrupts via OB 40.

Shows OB 40 start info for process interrupts from analog HS modules.

Explains insert/remove interrupts and OB 83 processing.

Discusses diagnostics for lost process interrupts, noting current limitations.

Illustrates response times between DP Master and ET 200S.

Provides an equation to approximate ET 200S response time.

Explains how digital input module reaction times depend on input delay.

States that response times for digital output modules correspond to output delay.

Describes conversion time, cycle time, and integration time for analog inputs.

Explains conversion time, cycle time, and settling time for analog outputs.

States response time for 4 IQ-SENSE modules is specified as cycle time.

Mentions response times for technology modules are in the Technical Data.

| Product Type | Interface Module |

|---|---|

| Compatible With | SIMATIC S7 |

| Number of I/O slots | Up to 63 |

| Number of Modules | 63 |

| Number of modules per station | Up to 63 |

| Number of DP masters | 1 |

| Number of DP slaves | 1 |

| Power Supply | 24 V DC |

| Supply voltage | 24 V DC |

| Current consumption | 100 mA |

| Communication Protocol | PROFIBUS DP |

| Communication Interface | PROFIBUS DP |

| Data Transfer Rate | 9.6 kbps ... 12 Mbps |

| Protocols | PROFIBUS DP |

| Operating Temperature | -25 to +60 °C |

| Mounting type | DIN rail |

| Product type designation | IM151-1 |

| Type | Interface module |

| Series | SIMATIC ET 200S |

| Storage Temperature | -40 °C to +70 °C |

Loading...

Loading...