Cycle and reaction times

5.5 Interrupt response time

CPU 31xC and CPU 31x, Technical Data

Manual, 01/2006 Edition, A5E00105475-06

5-21

Calculation

The formula below show how you can calculate the minimum and maximum interrupt

response times.

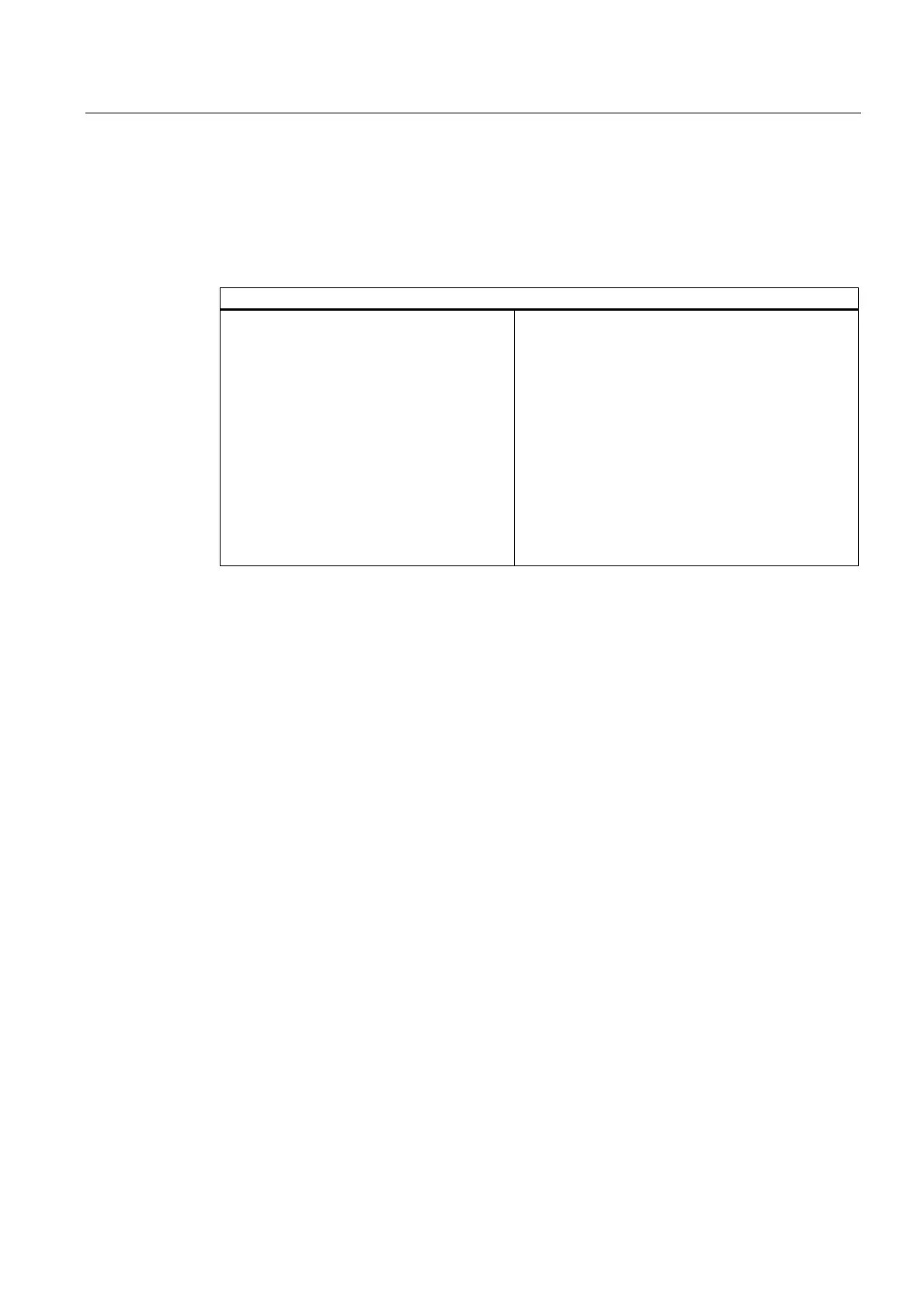

Table 5-14 Process and diagnostic interrupt response times

Calculation of the minimum and maximum interrupt reaction time

Minimum interrupt reaction time of the CPU

+ Minimum interrupt reaction time of the

signal modules

+ PROFINET IO update time (only if

PROFINET IO is used.)

+ DP cycle time on PROFIBUS DP (only if

PROFIBUS DP is used.)

= Quickest interrupt reaction time

Maximum interrupt reaction time of the CPU

+ Maximum interrupt reaction time of the signal

modules

+ 2 x PROFINET IO update time (only if PROFINET

IO is used.)

+ 2 x DP cycle time on PROFIBUS DP (only if

PROFIBUS DP is used.)

The maximum interrupt reaction time is longer when

the communication functions are active. The extra

time is calculated using the following formula:

tv: 200 μs + 1000 μs x n%

n = Setting of the cycle load as a result of

communication

Signal modules

The process interrupt response time of signal modules is determined by the following factors:

• Digital input modules

Process interrupt response time = internal interrupt preparation time + input delay

You will find these times in the data sheet for the respective digital input module.

• Analog input modules

Process interrupt response time = internal interrupt preparation time + input delay

The internal interrupt preparation time for analog input modules can be neglected. The

conversion times can be found in the data sheet for the individual analog input modules.

The diagnostic interrupt response time of signal modules is equivalent to the period that

expires between the time a signal module detects a diagnostic event and the time this signal

module triggers the diagnostic interrupt. This short time can be neglected.

Process interrupt processing

Process interrupt processing begins after process interrupt OB40 is called. Higher-priority

interrupts stop process interrupt processing. Direct I/O access is executed during runtime of

the instruction. After process interrupt processing has terminated, cyclic program execution

continues or further interrupt OBs of equal or lower priority are called and processed.

See also

Overview (Page 5-1)

Loading...

Loading...