The following table gives you an overview of the encoders that can be connected and what

you should take into account here.

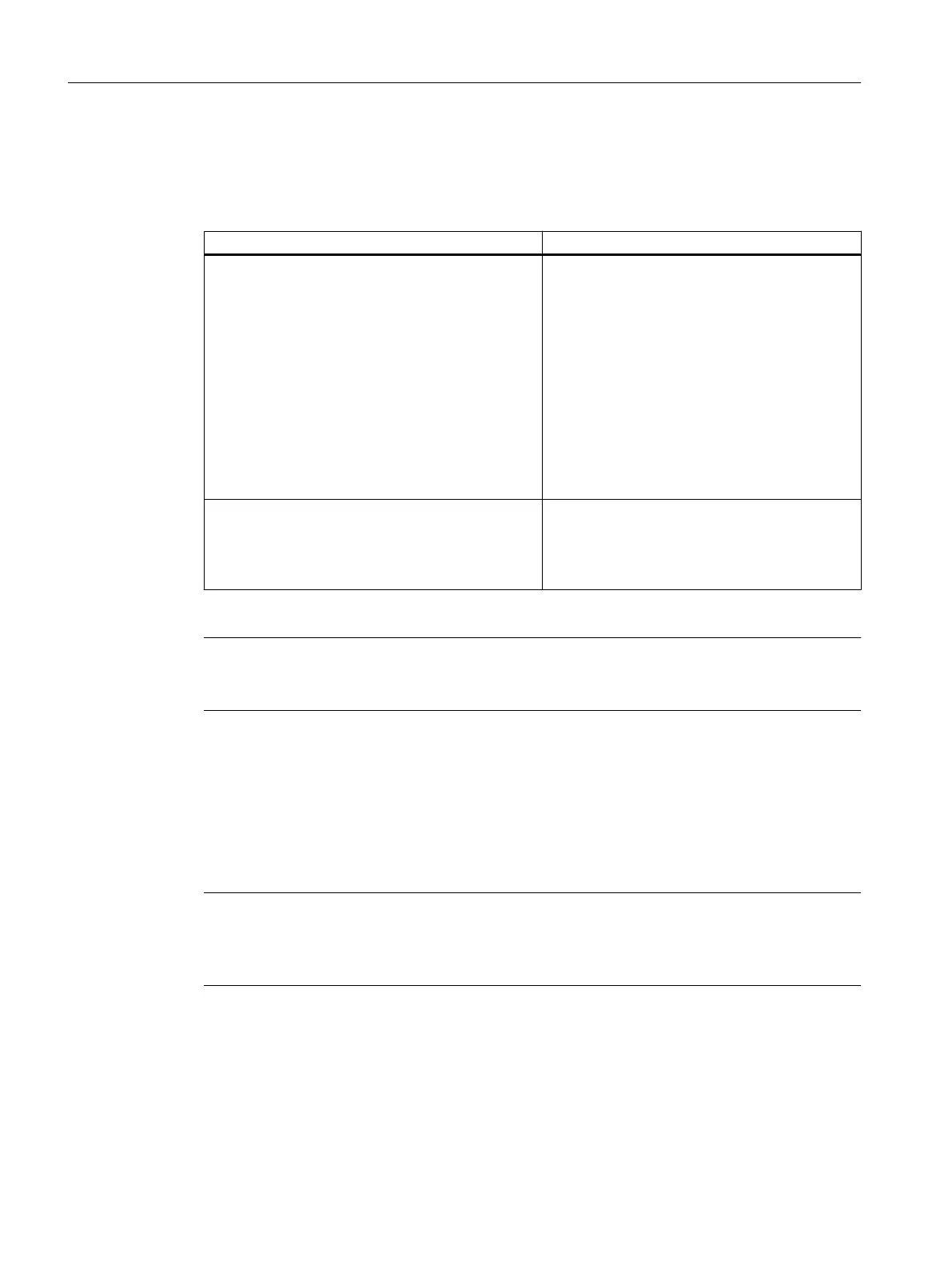

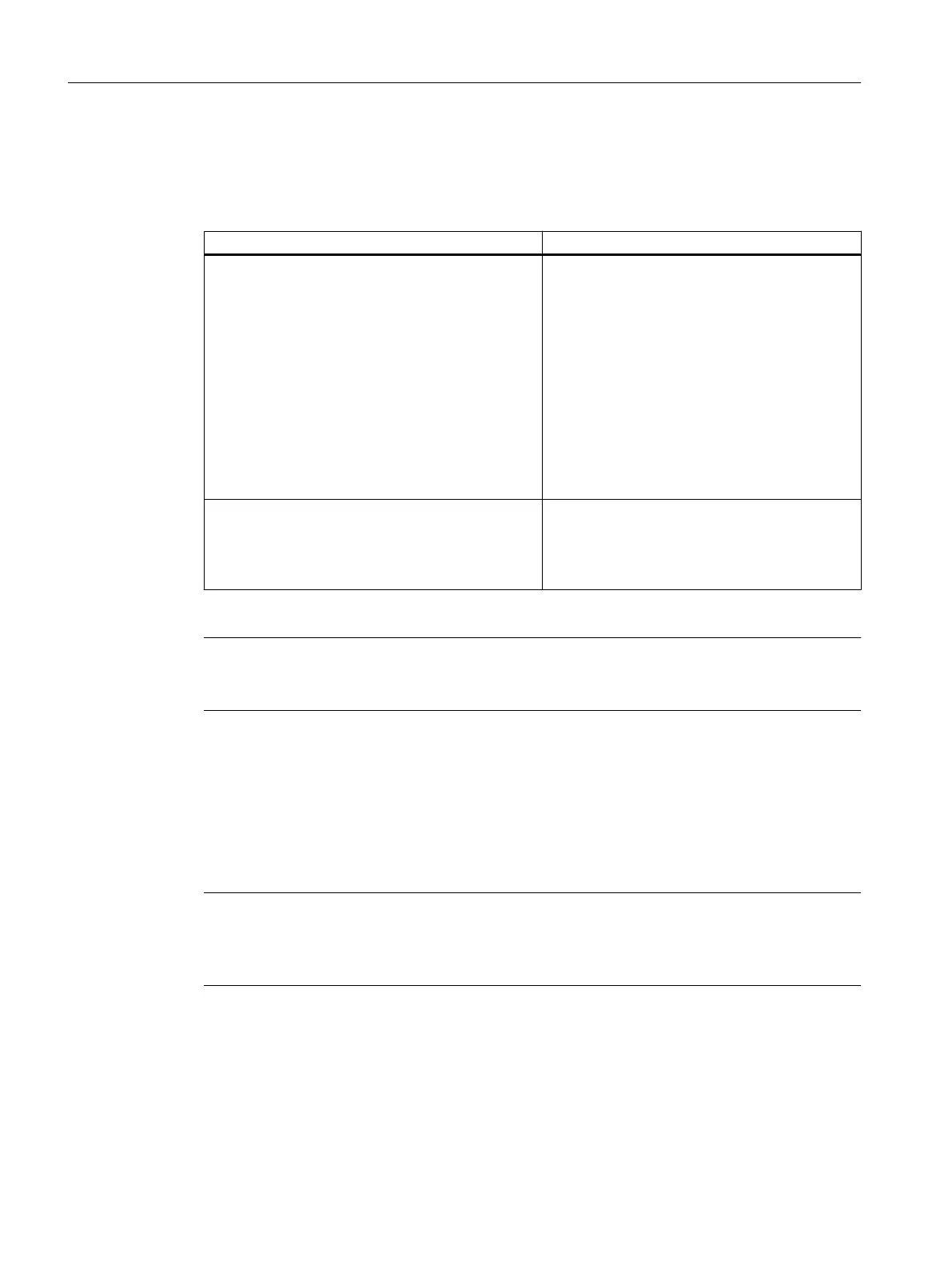

Table 4-11 Encoders which can be connected

Encoder Connection to X3 to X6 of the C230-2/C240

Rotary encoders

● Incremental encoders with 5 V encoder power

supply and TTL/RS422 interface

● Incremental encoders with 24 V encoder power

supply and TTL/RS422 interface

● Absolute encoders (single/multi-turn) with 24 V

encoder power supply and SSI interface

● Shaft position encoders with 5 V encoder power

supply and TTL/RS422 interface

● Rotor position encoder with SINE signals

● Resolver

● Direct

● Direct

● Direct

● Direct

● Via SIMODRIVE drive control using

incremental shaft encoder (WSG) interface

● Via SIMODRIVE resolver control using

incremental shaft encoder (WSG) interface

Linear encoders

● Length measurement systems with 5 V encoder

power supply and TTL/RS422 interface

● Linear encoders with SINUSOIDAL signals

● Direct

● Via EXE (external pulse shaper electronics)

Note

If you operate drives via the PROFIBUS DP, you do not need to connect any encoders to this

interface. The encoders are connected directly to the drive.

Encoder emulation (incremental shaft encoder (WSG) interface)

If the drive unit is equipped with encoder emulation, this can be connected instead of an

encoder. The drive control analyzes the information from a rotor shaft angle encoder and

provides information on the actual position to this interface by emulating the signals of an

incremental encoder.

Note

Please note the drive manufacturer's wiring specifications. As the encoder interface of the

C230-2, C240 is non-isolated, it may be necessary to take special measures for EMC on a

case-by-case basis.

Interfaces

4.6 Onboard measuring system interface (C230-2, C240)

SIMOTION C

58 Operating Instructions, 11/2016, A5E33441428B

Loading...

Loading...