PLC Subroutines Manual

46 6FC5397-0FP40-0BA0, 08/2013

Table 3-13 Outputs

C_out BOOL Coolant output

C_LED BOOL Coolant status display

Assigned global variables

COOLon MB150.0 Coolant on/off status

Relevant PLC machine data

None

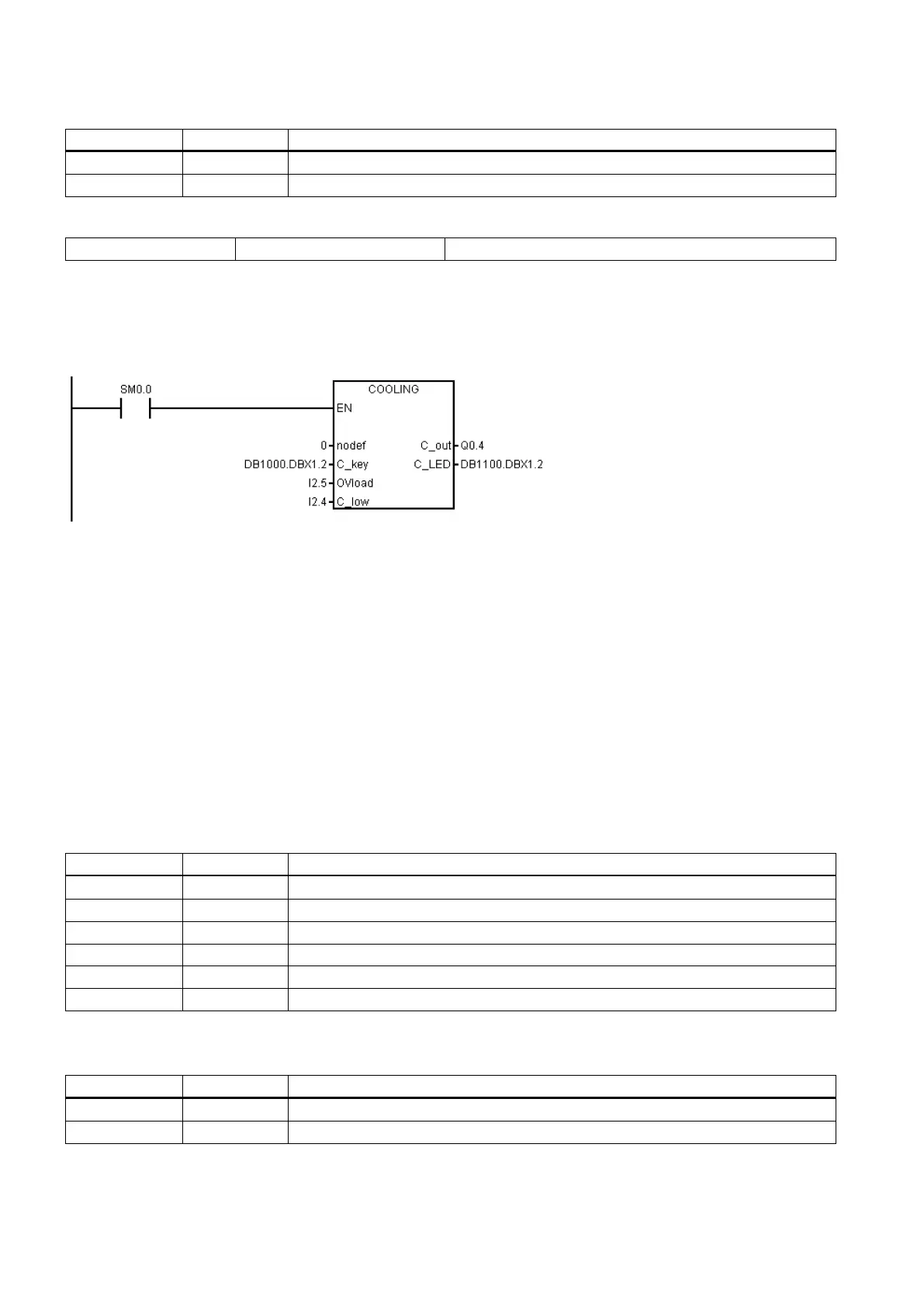

Example for calling subroutine 44

Subroutine 45 - LUBRICAT (control of lubricate)

Purpose

Subroutine 45 is used to control the lubrication according to specific time interval and duration (independent of the distance

that the axis has travelled). Meanwhile, a manual button is available to start the lubrication, and you can configure that the

lubrication starts automatically each time that the machine is powered up. Normally, lubricating starts automatically and

cyclically according to specified time interval

, and operates for a specific time

at each cycle. Lubrication stops in

case of an Emergency Stop, lubrication motor overload, low lubricant level.

This subroutine can activate following alarms:

● Alarm 700020: lubrication motor overload

● Alarm 700021: low lubricant level

Local variable definition

Table 3-14 Inputs

Lintv WORD Lubricating time interval (unit: 1 min)

Ltime WORD Lubricating time duration of each cycle (unit: 0.01 s, max. 327.67 s)

L_key BOOL Manual lubricating key (triggering signal)

L1st BOOL Mode selection: the lubrication starts at the first PLC scan

Ovload BOOL Lubricating motor overload

L_low BOOL Low lubricate level

Table 3-15 Outputs

L_out BOOL Lubrication output

L_LED BOOL Indicant for lubricate output

Loading...

Loading...