PLC Subroutines Manual

32 6FC5397-0FP40-0BA0, 08/2013

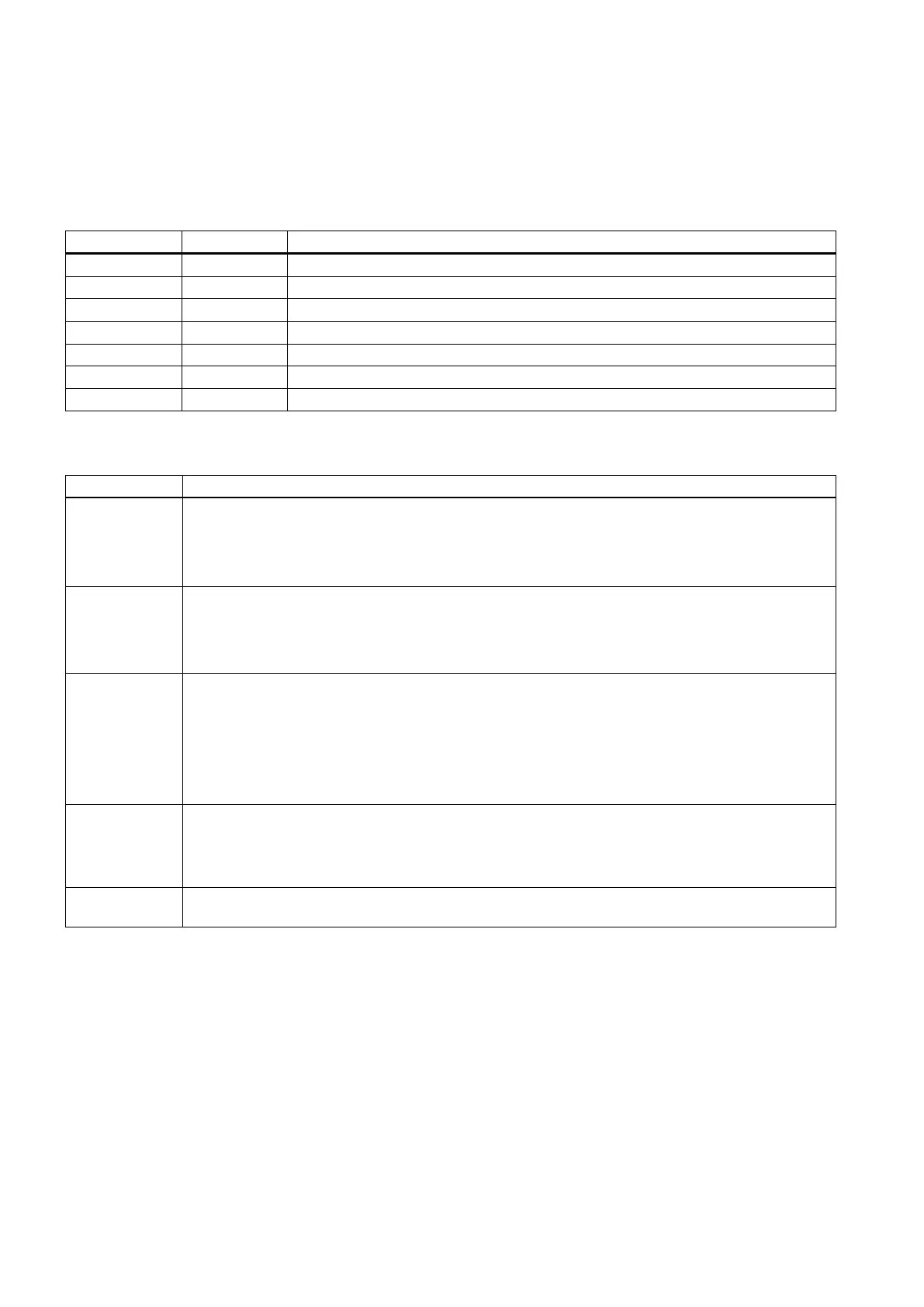

Table 3-1 USER_DATA_INT

14510 [12] - Layout of the traverse keys

14510 [13] 0.1s Time for spindle braking

14510 [20] - The maximum number of tool bits

14510 [21] 0.1s Turret clamping time

14510 [22] 0.1s Monitoring time for searching a tool

14510 [24] 1 min Lubricating intervals

14510 [25] 0.01s Lubricating duration

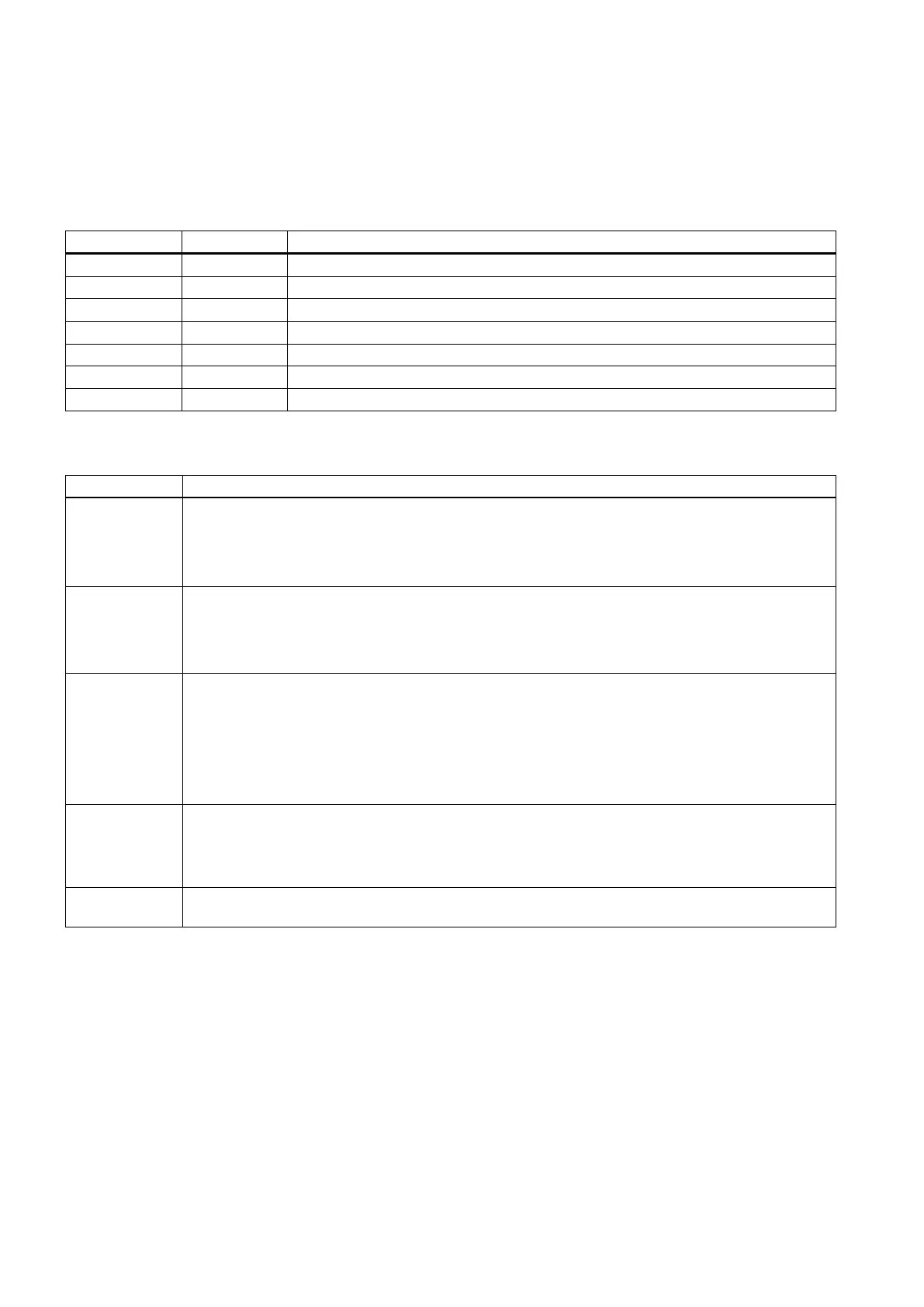

Table 3-2 USER_DATA_HEX

14512 [16] Bit 1: function of chip remover (milling)

Bit 2: function of safe door (milling)

Bit 3: when the function of safe door is active, it can be triggered by M01/M02 (milling).

Bit 7: handwheel assignment with the MCP / HMI

14512 [17] Bit 0: turret (turning); tool magazine (milling)

Bit 1: clamping function (turning)

Bit 2: tail stock function (turning)

Bit 3: selection between handwheel and hand-held unit (0: handwheel; 1: hand-held unit)

14512 [18] Special configurations for a machine

Bit 2: automatic lubrication after first power-on (factory setting)

Bit 4: signal that external spindle stops

Bit 5: spindle positioning direction

Bit 6: the hardware limit is independent from a PLC program

Bit 7: each feed axis has a hardware limit switch (activated when Bit 6 = 0)

14512 [19] Bit 1: function of spindle braking

Bit 2: password clearing by power-on (0: delete the password; 1: do not delete the password)

Bit 7: manual machine function (this function become active if you have installed licensed turning

machine system and called it with a PLC subroutine)

14512 [20] Bit 1: Spindle disable mode (0: disable by pressing the spindle stop key; 1: disable when detecting the

standstill speed)

1)

1)

When setting bit 1 to

, make sure that the speed control mode is active.

Conventions for the symbols used in the subroutines

The symbols used in the subroutines follow the conventions listed below:

● Leading characters designate the destinations of interface signals

– P_: to PLC interface

– H_: to HMI interface

– N_: to NCK interface

– M_: to MCP interface

Loading...

Loading...