PLC Subroutines Manual

6FC5397-0FP40-0BA0, 08/2013

47

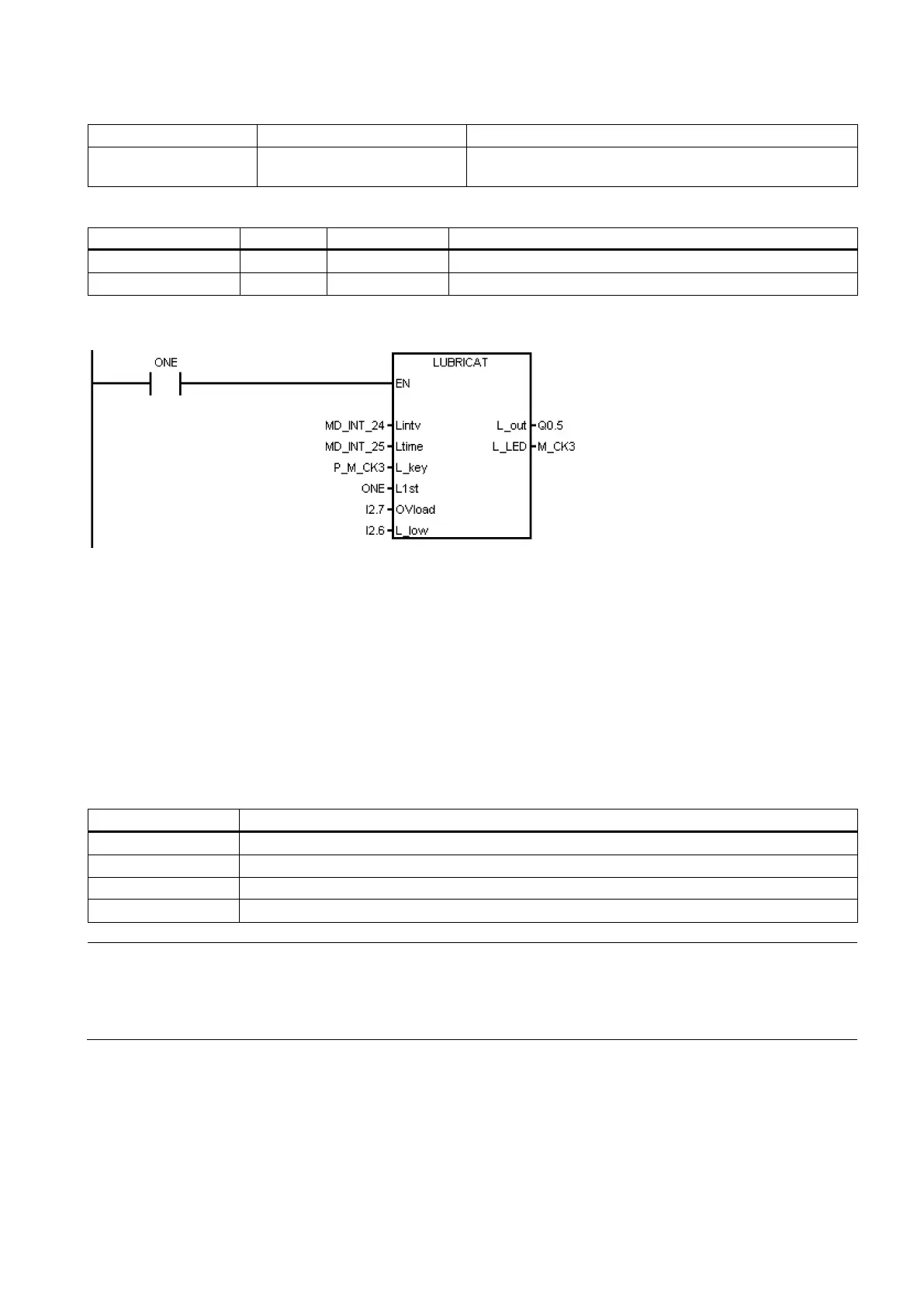

Assigned global variables

L_interval C24 Timer for the lubricating time intervals (unit: min)

L_time T27 Timer for very lubricating time duration (unit: 0.01s, max.

327.67 s)

Relevant PLC machine data

14510 [24] Min. - Lubricating time interval

14510 [25] 0.01 s 100 to 2,000 Lubricating time duration

Example for calling subroutine 45

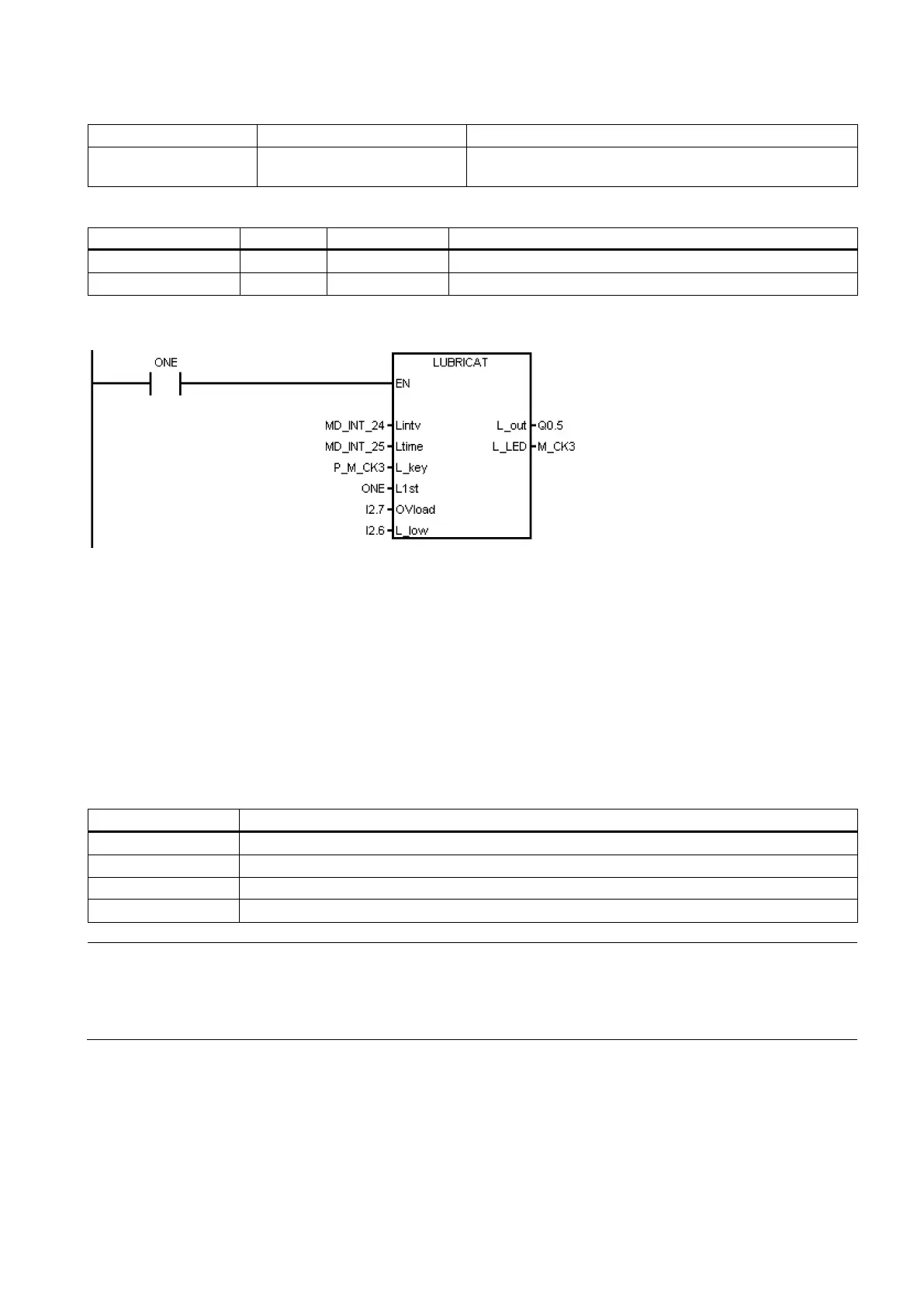

Subroutine 46 - PI_SERVICE (Asynchronous Subroutine Program)

Purpose

Subroutine 46 is for realizing functions like ASUP (Asynchronous Subroutine Program), deleting a password and reading

current tool number. ASUP function means the execution of PLCASUP1.SPF or PLCASUP2.SPF called by the PLC. The

SINUMERIK 808D ADVANCED provides two ASUPs for the PLC. The two ASUPs can not be simultaneously executed, and

the PLCASUP1.SPF has a higher priority over the PLCASUP2.SPF.

In a program, firstly you can initialize the ASUP1 and ASUP2 by setting "PI index" (DB1200.DBB4001) and "NCK read/write

start" (DB1200.DBX4000.0), and then use a rising edge to trigger "ASUP1 start" (DB3400.DBX0.0) and "ASUP2 start"

(DB3400.DBX1.0).

Table 3-16 Relevant machine data

10702 IGNORE_SINGLEBLOCK_MASK

11602 ASUP_START_MASK

11604 ASUP_START_PRIO_LEVEL

20116 IGNORE_INHIBIT_ASUP

The SINUMERIK 808D ADVANCED provides two user ASUPs. In the sample application, ASUP1 is used for manual tool

change and ASUP2 is used for the MANUAL MACHINE of the workpiece on a turning machine with the Manual Machine

Plus function.

Loading...

Loading...