Cycles

2.5 Turning cycles

Turning Part 2: Programming (Siemens instructions)

Programming and Operating Manual, 05/2012, 6FC5398-5DP10-0BA0

189

NOTICE

To be able to use this cycle, a speed-controlled spindle with position measuring system is

required.

Sequence

Position reached prior to cycle start:

Starting position is any position from which the programmed thread starting point + run-in

path can be approached without collision.

The cycle creates the following sequence of motions:

● Approach of the starting point determined in the cycle at the beginning of the run-in path

for the first thread turn with G0

● Infeed for roughing according to the infeed type defined under VARI.

● Thread cutting is repeated according to the programmed number of roughing cuts.

● The finishing allowance is removed in the following step with G33.

● This step is repeated according to the number of idle passes.

● The whole sequence of motions is repeated for each further thread turn.

Explanation of the parameters

DM1 and DM2 (diameter)

Use this parameter to define the thread diameter of starting and end point of the thread. In

the case of internal threads, this is the tap-hole diameter.

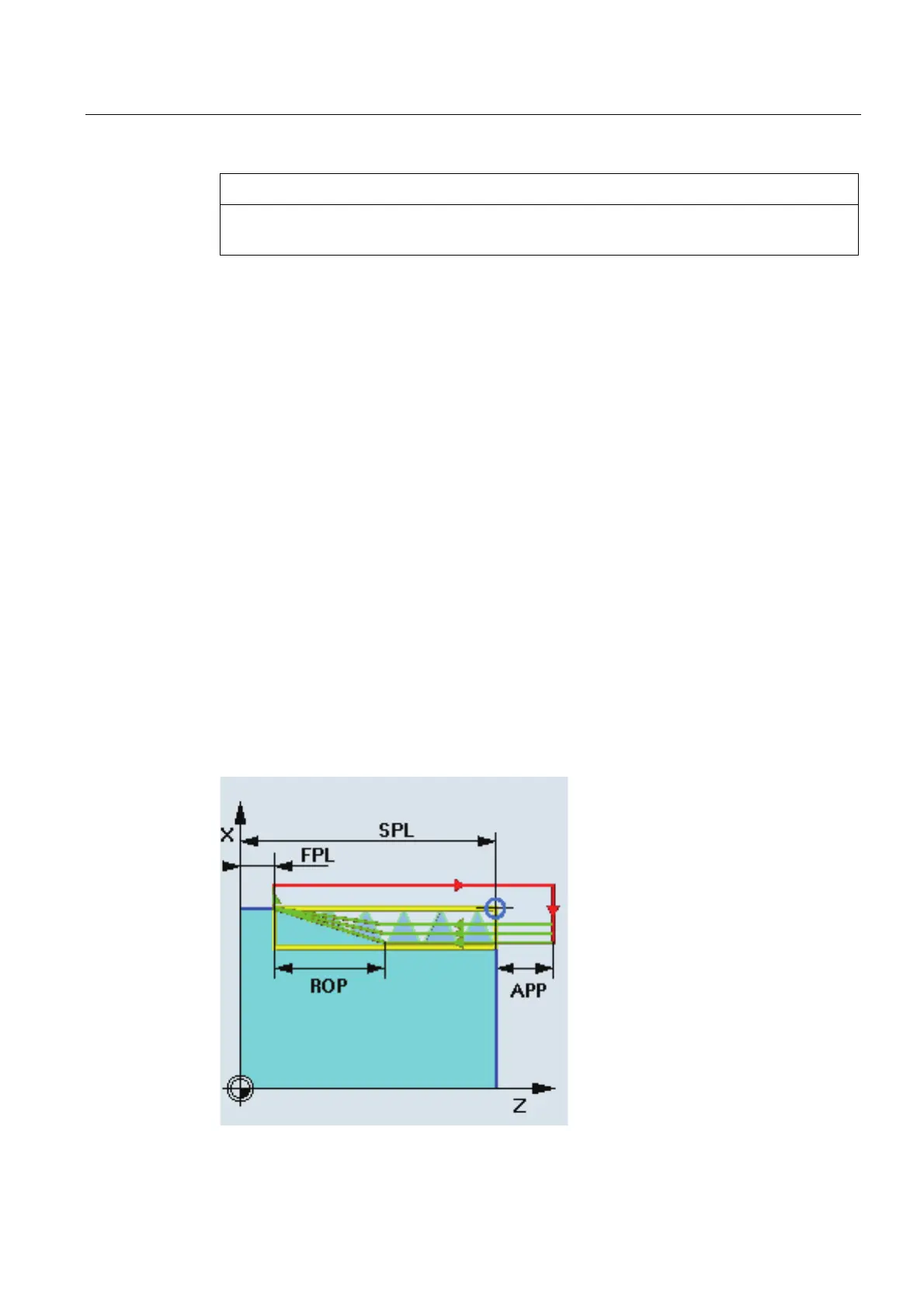

Interrelation SPL, FPL, APP and ROP (starting, end point, run-in and run-out path)

Loading...

Loading...