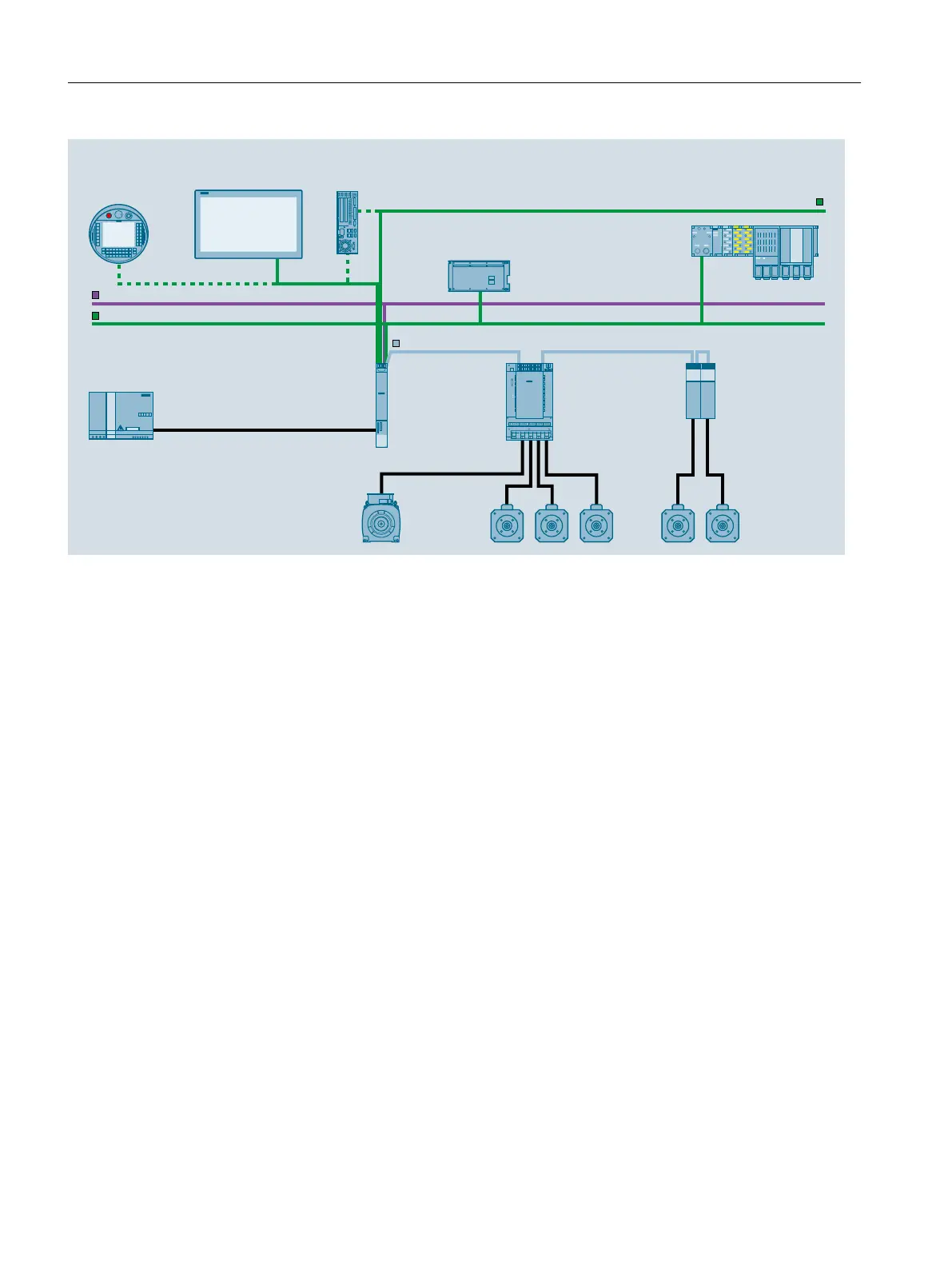

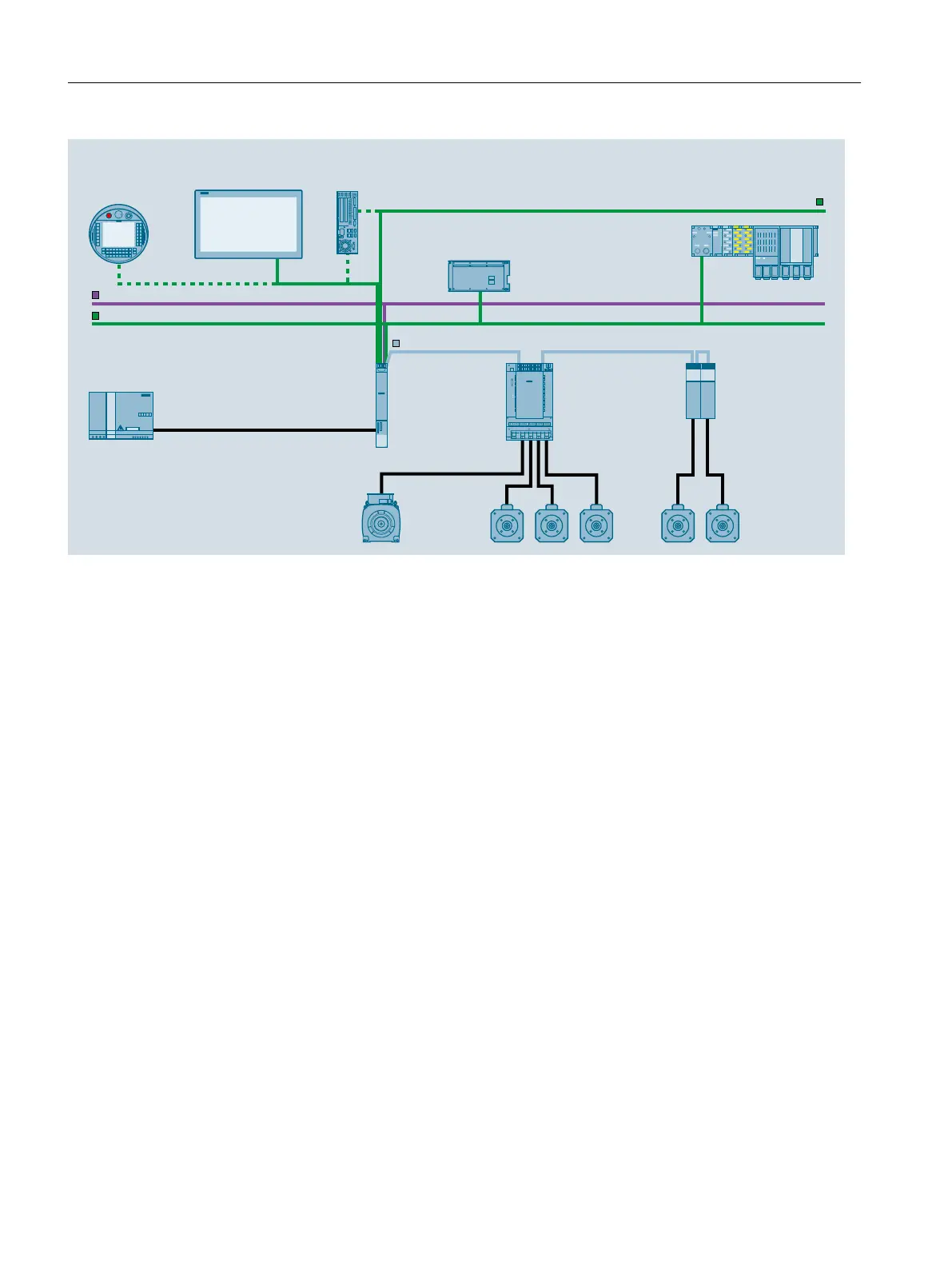

)HHG

PRWRUV

).

)HHG

PRWRUV

).

2SHUDWRUSDQHOIURQWZLWK

7&8

3RZHUVXSSO\

6,1$0,&66

0RWRU0RGXOHIRUPDW

%RRNVL]H&RPSDFW

3+VSLQGOH

PRWRU

352),%86

,QGXVWULDO(WKHUQHW

'5,9(&/L4

+7

6,0$7,&,3&

33'31

33b'b$b31

6,1$0,&66

&RPEL

352),1(7

1&8

6,0$7,&

(7SUR

Figure 2-2 Topology example

Networking

SINUMERIK ONE offers integrated PROFINET functionality.

PROFINET IO is supported:

● As part of PROFINET, PROFINET IO is a communication concept that is used to implement

modular, distributed applications. PROFINET IO is based on Industrial Ethernet and allows

distributed field and I/O equipment to be connected to the central processing unit.

● 128 PROFINET IO devices can be operated on the NCU as an IO controller.

2.3 Variants

The scalability of the hardware and software – both from a CNC perspective and in terms of

operation – means the SINUMERIK ONE can be used in many sectors. The possibilities range

from simple positioning tasks up to complex multi-axis systems.

Application areas and performance

● On the NCU, the number of axes and/or the performance of the drive control can be

increased to 31 axes. This is achieved through the use of the NX modules. The NCU can be

expanded by up to 5 NX modules for increased performance of the drive control and number

of axes.

● Use of an NCU 1760 is recommended for maximum dynamics and accuracy in mold making

or in the high-speed cutting sector.

System overview

2.3 Variants

NCU 1760

20 Equipment Manual, 02/2020, A5E45627861B AB

Loading...

Loading...