18

10.13

SIGNODE BXT2-19

1

2

3

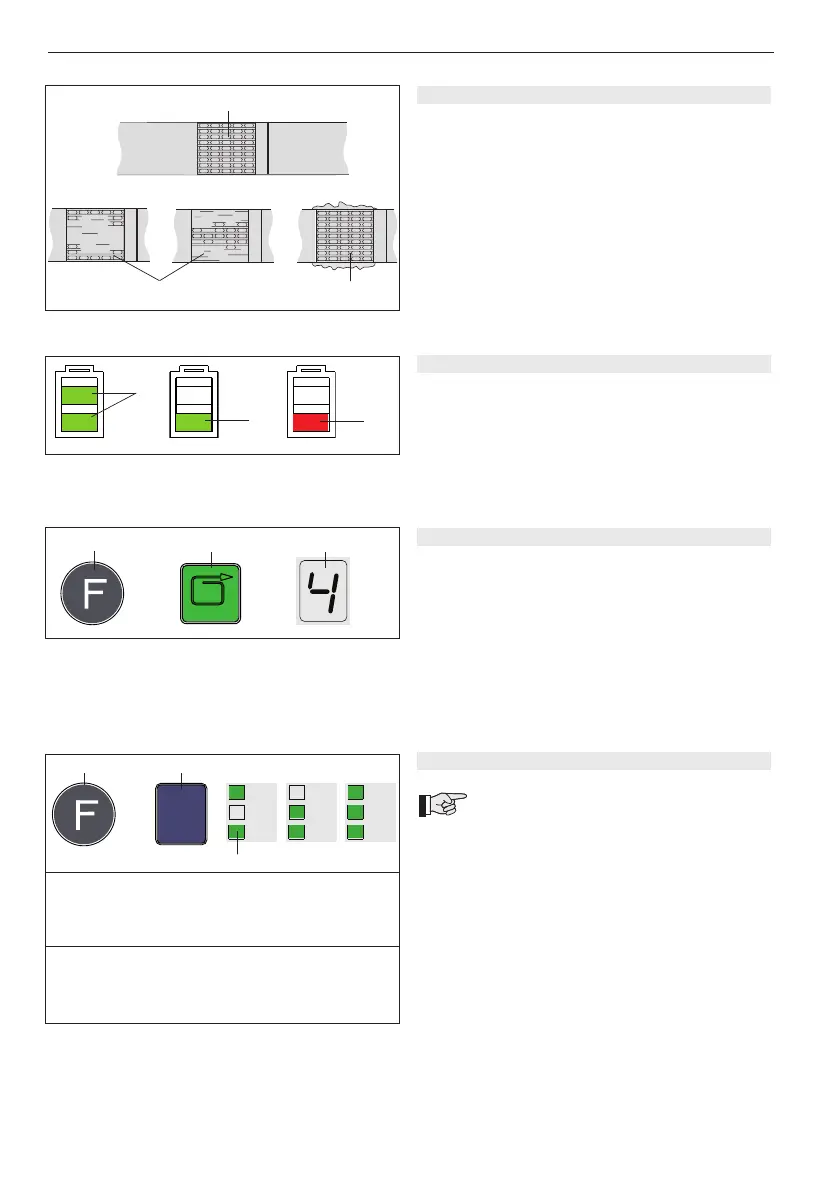

Fig. 9

1

3

2

Fig. 10

5.3 CHECKING THE SEAL

– Checkappearanceofseal(seeg.9)regularly.Ifthe

straps are poorly welded, check the welding time

setting (refer to chapter 5.7).

1 Good seal (the complete surface is cleanly welded

without excess material being forced out sideways).

2 Poorly welded seal (not welded over the complete

surface), welding time too short.

3 Poorly welded seal (excess material is forced out

sideways), welding time too long.

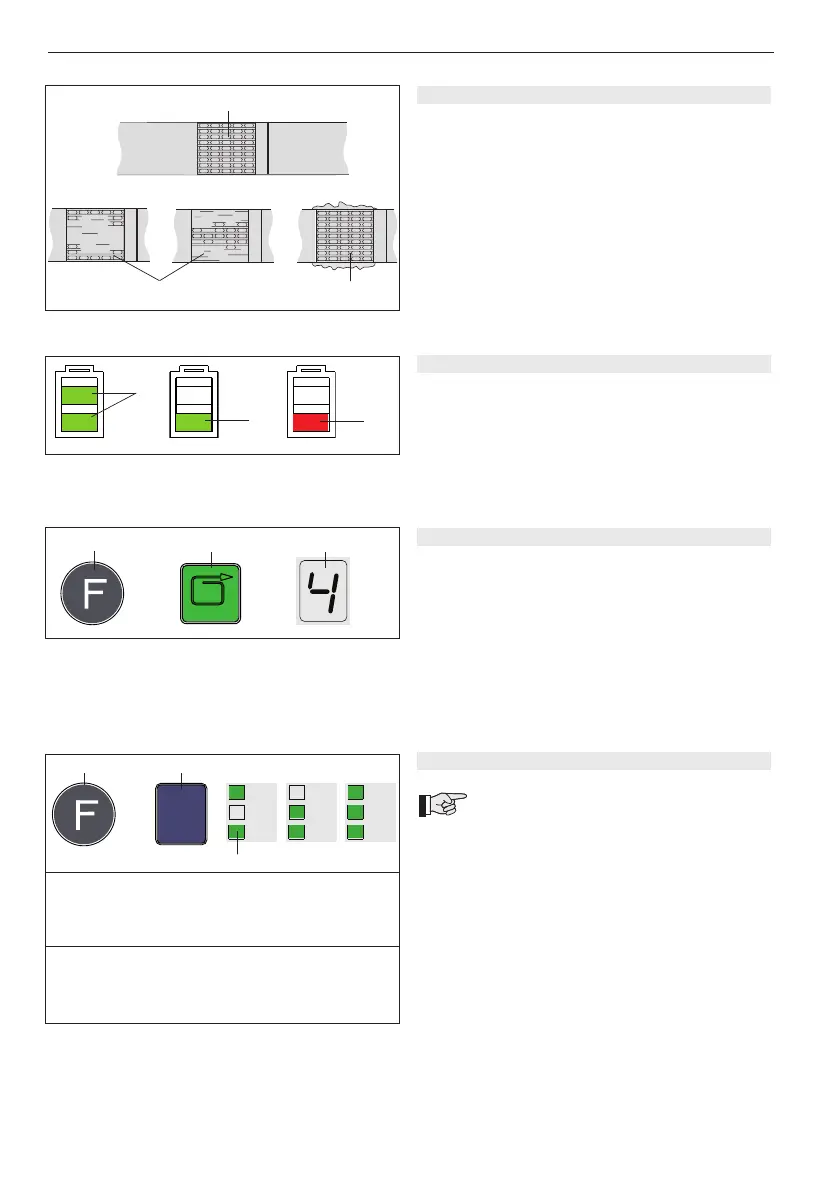

5.4 CHECKING BATTERY CHARGE

– Read off battery charge on LED indicator (Fig. 10):

1 = Green indicator: maximum battery charge

2 = Green indicator: good battery charge

3 = Red indicator: empty battery

(Battery must be charged)

➟

Fig. 11

1

2

3

=

5.5 SETTING STRAP TENSION

– Pressthe„Function“button(11/1)briey.

– Press the „Strap tension“ button (11/2) until the

ashingdigitaldisplay(11/3)showstherequiredstrap

tension. Wait two seconds until the new setting is

saved.

1 = min. strap tension approx. 400/1200 N*

(88/264 lbs.) (PP)

9 = max. strap tension approx. 1600/4000 N*

(353/882 lbs) (PET)

* refer to Chapter 5.7

5.6 SETTING SOFT TENSION

The following two strap tension ranges can

be set on the tool:

A = 1200–4000 N (264–882 lbs.)

standard, PET straps

B = 400–1600 N (88–353 lbs.)

Soft tension*, PP straps

* Soft tension: tension wheel starts slowly. Prevents

excessive dirt on PP straps.

Setting soft tension:

– Pressthe„Function“button(12/1)briey.

– Press the „Mode of operation“ button (12/2) several

times until the green „SOFT“ LED indicator (12/3)

lights up together with the desired mode of operation

(refer to chapter 5.5).

AUTO

MAN.

SOFT

➟

Fig. 12

1

2

3

=

MAN.

MAN.

MAN.

A)

1 2 3 4 5 6 7 8 9

1200 1550 1900 2250 2600 2950 3300 3650 4000 N

264 341 418 496 573 650 727 804 882 lbs.

B)

1 2 3 4 5 6 7 8 9

400 550 700 850 1000 1150 1300 1450 1600 N

88 121 154 187 220 253 286 319 353 lbs.

Loading...

Loading...