EN

6

Vibration hazards

Exposuretovibrationcancausedisablingdamagetothenervesandbloodsupplyofthehands

andarms.Notallvibrationhazardscanbeeliminatedbytooldesignorconstruction,andsome

residualrisksremain.Checkthevibration-emissionvalue(obtainedusingISO28927-3)shownin

thespecicationtable.Ensuretheriskitrepresentsisassessedandmanaged.Iftheriskcannotbe

managedsothatitfallswithinacceptablelimits,thendonotusethetool.

Takethefollowingstepstoreduceriskofvibration-relatedinjury:

a) Wearwarmclothingwhenworkingincoldconditions.Keephandswarmanddry.

b) Ifnumbness,tingling,painorwhiteningoftheskinofngersorhandsisexperienced,stop

usingthetool,informemployer(whereappropriate)andconsultaqualiedhealthprofessional.

c) Operateandmaintainthetoolasrecommendedintheinstructionstopreventanunnecessary

increaseinvibrationlevels.

d) Whereappropriate,supporttheweightofthetoolinastand,tensionerorbalancer.

e) Theriskfromvibrationisgenerallygreaterwhenthegripforceishigher.Holdthetoolwitha

lightbutsafegrip,takingaccountoftherequiredhandreactionforces.

f) Ensurethetoolandaccessoriesareproperlymountedandingoodrepair:improperlymounted

ordamagedtoolscancauseexcessivevibration.

WARNING:Beawareofpaintnishesortreatmentsthatmayhavebeenappliedtothematerial

thatisbeingworkedon.Manytreatmentscancreatedustthatistoxic,orotherwiseharmful.If

workingonabuildingconstructedpriorto1960,thereisanincreasedchanceofencountering

lead-basedpaints.

WARNING:Thedustproducedwhengrindingobjectspaintedwithlead-basedpaintsis

particularlyhazardoustochildren,pregnantwomen,andpeoplewithhighbloodpressure.Donot

allowthesepeopleneartheworkarea,evenifwearingappropriatepersonalprotectiveequipment.

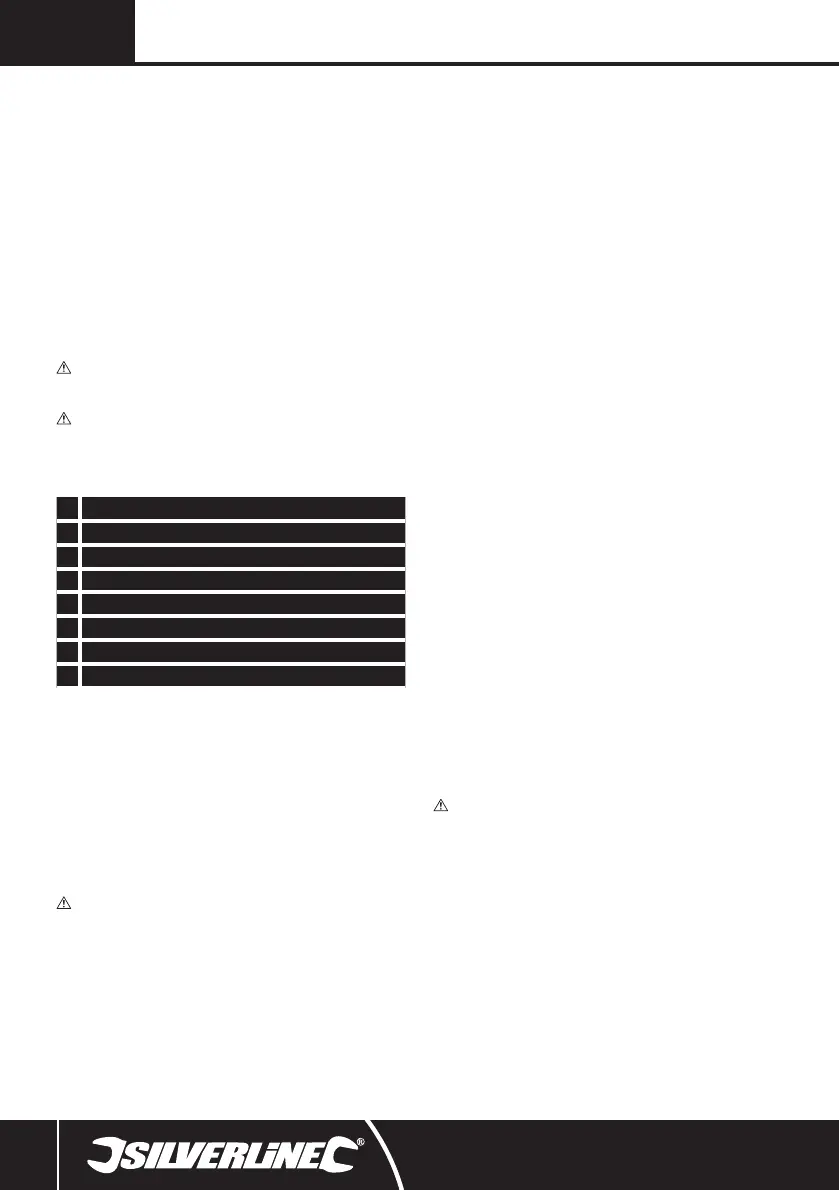

1 Body Cover

2 Power Regulator

3 Speed Control

4 Handle

5 Quick Connector

6 Backing Pad

7 Spindle Lock

8 Drive Spindle

Product Familiarisation

Intended Use

ThisproductisaDualActionAirSanderpoweredbycompressedairfromacompressor,forlight

removalofmaterialssuchaswood,paintandbodyller.

Notintendedforcommercialuse.

ThetoolmustONLYbeusedforitsintendedpurpose.Anyuseotherthanthosementionedinthis

manualwillbeconsideredacaseofmisuse.Theoperator,andnotthemanufacturer,shallbeliable

foranydamageorinjuryresultingfromsuchcasesofmisuse.Themanufacturershallnotbeliable

foranymodicationsmadetothetool,norforanydamageresultingfromsuchmodications.

Unpacking Your Tool

WARNING:Thistoolisnotsuitableforgrindingorcutting.Misuseofthisproductisdangerous

andcouldresultinseriousinjury.

• Carefullyunpackandinspectyourtool.Fullyfamiliariseyourselfwithallitsfeaturesand

functions.

• Ensurethatallpartsofthetoolarepresentandingoodcondition.Ifanypartsaremissingor

damaged,havesuchpartsreplacedbeforeattemptingtousethistool.

Before Use

Fitting the quick connector

ThistoolissuppliedwithtwodifferentmaleairlineQuickConnectors(5)(Fig.I):

• EQ-4–commonlyusedinEurope

• EN-6–mainlyusedintheUK

Pleasechoosetheconnectorthatiscompatiblewiththeairlinesystemyouareusing,andinstallas

outlinedbelow:

1. ApplysomePTFEtape(notincluded)tothescrewthreadsoftheQuickConnector.Thiswillhelpto

maintain an airtight seal

Note: ApplyPTFEtapetightlyandinaclockwisedirection,soitdoesnotcomeoffwhenthethreadis

screwedintothetool.

2. Removetheprotectiveplugfromtheairinlet

3. Usingaspanner(notincluded)screwtheQuickConnectorintotheairinletlocatedatthebaseofthe

Handle(4)

4. Connecttoairline,pressurisecarefullyandcarryoutaleakcheck(e.g.bysprayingsmallamountsof

soapywaterontotheoutsideoftheconnectors)

• AirlinesttedwithmatchingfemaleQuickConnectorswillnowbeapushttothetool

Air supply connection

• Thistoolshouldbeconnectedtoaclean,dryairsupplywithinlineoilerandwaterseparator

• Donotallowsupplypressuretoexceedthemaximumstated(see'Specication')

• Ensurethatwaterisdrainedfromairsystemdaily

• Ensurethatallpartsofthesystem(hoses,couplers,etc.)arecorrectlyratedfortheairpressureto

be used

Attaching the backing pad

1. ScrewtheBackingPad(6)intotheDriveSpindle(8)turningclockwise.Tightenbyhand

2. Useasuitablespanner(notincluded)tostoptheDriveSpindlerotatingifneeded

3. AdoptthisproceduretoremovetheBackingPad,butturnanti-clockwisetounscrew

Attaching the sanding disc

Note: Onlyuseabrasivesandingdiscsof150mmdiameter,withadhesivebacking.

1. RemoveoldsandingsheetsbypeelingthemofftheBackingPad(6)

2. CleananyadhesiveresidueofftheBackingPad

3. Peeloffthebackingpaperfromtheadhesivesideofthenewsandingsheet

4. CentrethenewsandingsheetcorrectlyontheBackingPad

5. PushthesandingsheetontotheBackingPadandcheckitissecurelyattached

Setting tool power

1. Holdtheproductrmly,withouttheBackingPad(6)attached

2. SqueezetheSpeedControl(3)fully

3. WhilstholdingtheSpeedControl,turnthePowerRegulator(2)slowly

Note: Asitturnsyouwillhearthepowerincreaseanddecrease.

4. Setspeedasrequired

5. ReleasetheSpeedControl

Changing orbital mode

WARNING:Disconnecttoolfromairsupplybeforemakinganyadjustments.

Thisproducthastwomodes:

Fixed orbit:

ThesandingpadwillrotateONLYarounditscentralaxis,likeawheel.Itcreatesacircularpatternonthe

sandedmaterial.

1. Inxedorbit,theDriveSpindle(8)andBackingPad(6)donotrotatefreelyaroundtheiraxis

2. Toselectxedorbit,rotatetheSpindleLock(7)sothattheknurledfacelinesupwiththeatonthe

DriveSpindle(Fig.II)

3. CheckthattheDriveSpindle(8)cannotrotatefully,itshouldstopwhenittouchestheSpindleLock

Random orbit:

Thesandingpadorbitsarounditseccentricpath.Itcreatesarandomsandingpatterninalldirectionson

thesandedmaterial.

1. Inrandomorbit,theDriveSpindle(8)andBackingPad(6)canrotatefreelyandfullyaroundtheiraxis

2. Toselectrandomorbit,rotatetheSpindleLock(7)sothatoneatsidefacestheDriveSpindle(Fig.III)

3. ChecktheDriveSpindleisabletorotatefullythrough360°,anddoesnottouchtheSpindleLock

580430_OwnerManual.indd 6580430_OwnerManual.indd 6 12/04/2023 11:0312/04/2023 11:03

Loading...

Loading...