84

EN

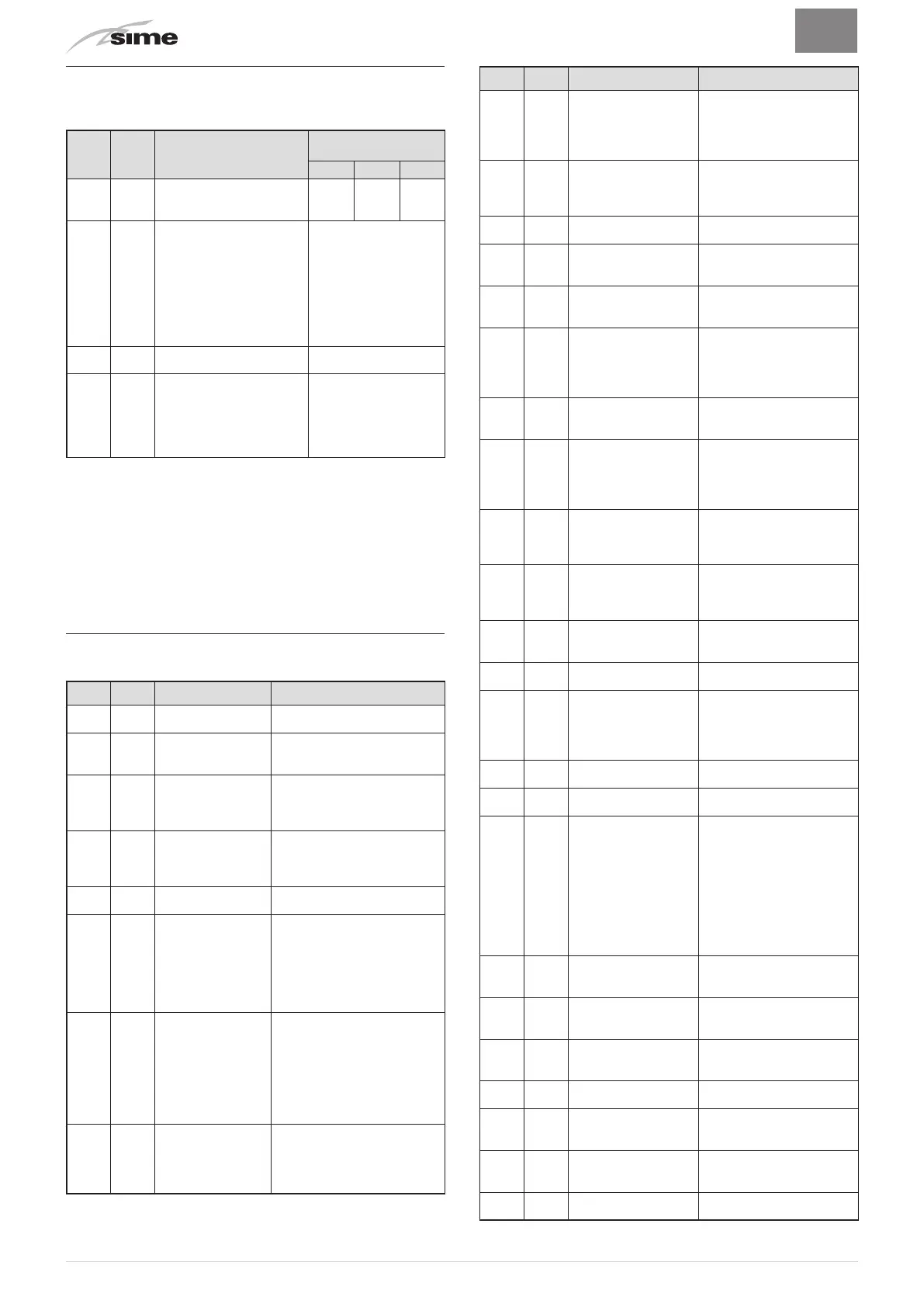

8.5 Unscheduled maintenance

If replacing the

electronic board

, the user MUST set the parame-

ters as indicated in the table and in the sequence shown.

Type No. Description

Setting for

Brava Slim

BF

25 30 40

PAR 01

Index showing boiler power

in kW

0 = 24; 1 = 30; 2 = 40

0 1 2

PAR 02

Hydraulic configuration

0 = rapid

1 = storage tank with ther-

mostat or heating only

2 = hot water t

ank with

sensor

3 = bithermic

4=instant with solar power

input

0

PAR 03

Gas Type Configuration

0 = G20; 1 = LPG

0 or 1

PAR 04

Combustion configuration

0 = sealed chamber with

combustion control

1 = open chamber with

smoke thermostat

2 = Low NOx

0

To enter "Parameter setting and display"refer to the indications

provided in the specific section.

Once the parameters in the table have been set, you must carry

out the "Automatic calibration procedure".

If the

gas valve

and/or the

ignition/detection electrode

and/or the

fan

are replaced, the user must still carry out the entire phase

of "Automatic calibration procedure" described in the specific

section.

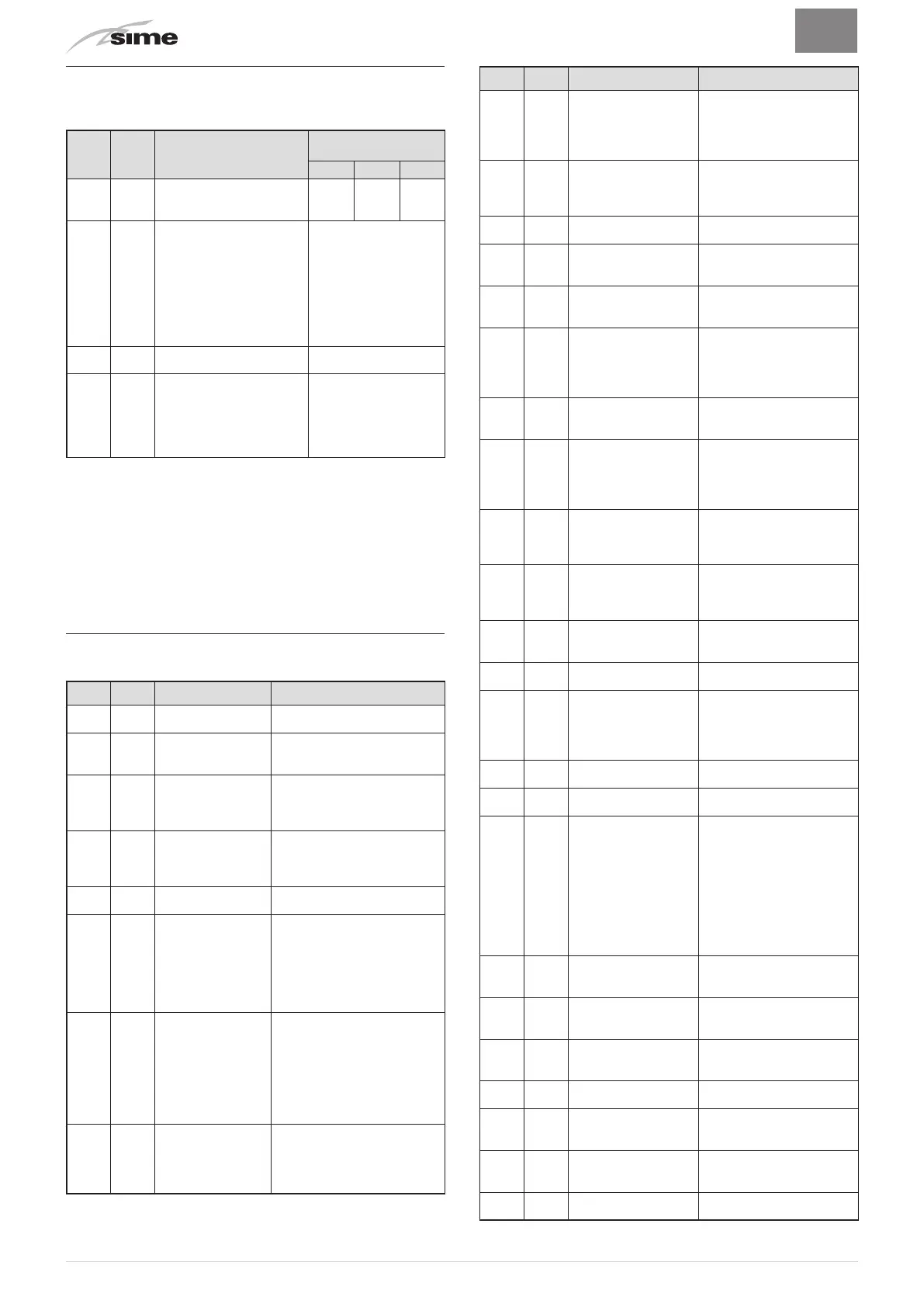

8.6 Malfunction codes and possible solutions

LIST OF MALFUNCTION/FAULT ALARMS

Type No. Fault Solution

ALL 01 Smoke thermostat

- Contact the Technical Assis-

tance Centre

ALL 02

Low wat

er pressure

in system

- Restore pressure

- Check for any leaks in the

system

ALL 03

High water pressure

in system

- Empty the system via the

drain valve on the hydraulic

assembly and bring the pres

-

sure to approximately 1.2 bar

ALL 04

Domestic hot wat

er

sensor fault (return

sensor fault for T

models)

- Check connections

- Check the sensor is working

ALL 05 Delivery sensor fault

- Check connections

- Check the sensor is working

ALL 06 No flame detection

- Check the integrity of the

electrode and check that it is

not grounded

- Check gas availability and

pressure

- Check the integrity of the gas

valve and the card

ALL 07

Sensor or safety

thermostat inter

-

venes

-

Check the sensor or thermo

-

stat connections

-

Deaerate the system

- Check the bleed valve

- Replace the sensor or the

thermostat

- Check that the pump impeller

is not blocked

ALL 08

Fault in the flame

detection circuit

- Check the integrity of the

electrode and check that it is

not grounded

- Check the integrity of the gas

valve and the card

Type No. Fault Solution

ALL 09

No water circulating in

the system

- Check the rotation of the

pump rotor

- Check the electrical con-

nections

-

Replace the pump

ALL 10 Auxiliary sensor fault

- Check PAR 02 "hydraulic

configuration"

- Check the electrical con

-

nection

ALL 11

Gas val

ve modulator

disconnected

- Check the electrical con

-

nection

ALL 12

Domestic hot wat

er

sensor fault in tank

mode

- Set the parameter PAR 04

(Combustion configuration)

to 0

ALL 13

Smoke probe inter-

vention

-

Check the sensor is

working

- Replace the smoke probe

ALL 14 Smoke probe fault

- Replace the smoke probe

- Check the electrical con-

nection of the smoke probe

-

Contact the Technical

Assistance Centre

ALL 15

Fan check cable dis-

connected

-

Check the connection

cable between the fan and

the board

ALL 18 Condensate level fault

- Check for any clogging in

the pipe which takes the

condensate to the siphon

- Check that the siphon is

not clogged

ALL 28

Maximum number of

consecutive resets

reached

- Wait 1 hour and try un-

blocking the board again

-

Contact the Technical

Assistance Centre

ALL 30

Return sensor fault

(boiler sensor fault for

T models)

- Replace the return probe

- Check parameters

- Contact the Technical

Assistance Centre

ALL 37

Fault due to low net-

work voltage

-

Check the voltage

- Contact your network

provider

ALL 40

Incorrect network

frequency detected

- Contact your network

provider

ALL 41

Flame loss more than

6 consecutive times

- Check the ignition/detec

-

tion electrode

-

Check the gas supply

(open valve)

- Check mains gas pressure

ALL 42 Button fault

- Check that buttons are

working

ALL 43

Open Therm communi

-

cation fault

-

Check the OT electric

connection

ALL 44

No flame valve opening

time sum anomaly

- Check for the presence

of water hammer on the

hot water system and, if

present, mount a water

hammer arrestor

- Check for any abnormal

requests on the room

thermostat

- Contact the Technical

Assistance Centre

ALL 56

Lock for ∆T delivery/

return over max limit

(open vent)

- Contact the Technical

Assistance Centre

ALL 57

Lock for flow temper

-

ature (FT) check (open

vent)

-

Contact the Technical

Assistance Centre

ALL 62

Self-calibrating proce

-

dure is required

-

Carry out the self-cali

-

brating procedure (see the

specific section)

ALL 72

Inc

orr

ect positioning of

the delivery sensor

- Check delivery sensor

operation and position

ALL 74

Second delivery sensor

fault

- Check second delivery

sensor operation and

position

ALL 77

EV2 SGV current max/

min absolute limits

error

- Check gas valve and board

ALL 78

EV2 SGV current upper

limit error

- Check gas valve and board

Loading...

Loading...