5

HTE302172

33/46

6

Note: Two external rheostats or a current control must have been wired before the function

cord “rnt X” will be set for “X=2” or “X=1”.

Note: “Panel” in the table means running by stored data, the stroke and

the driving frequency.

Note: On the maximum setting of the external rheostat the stroke data appears

on the display is not “100” but “over 95”.

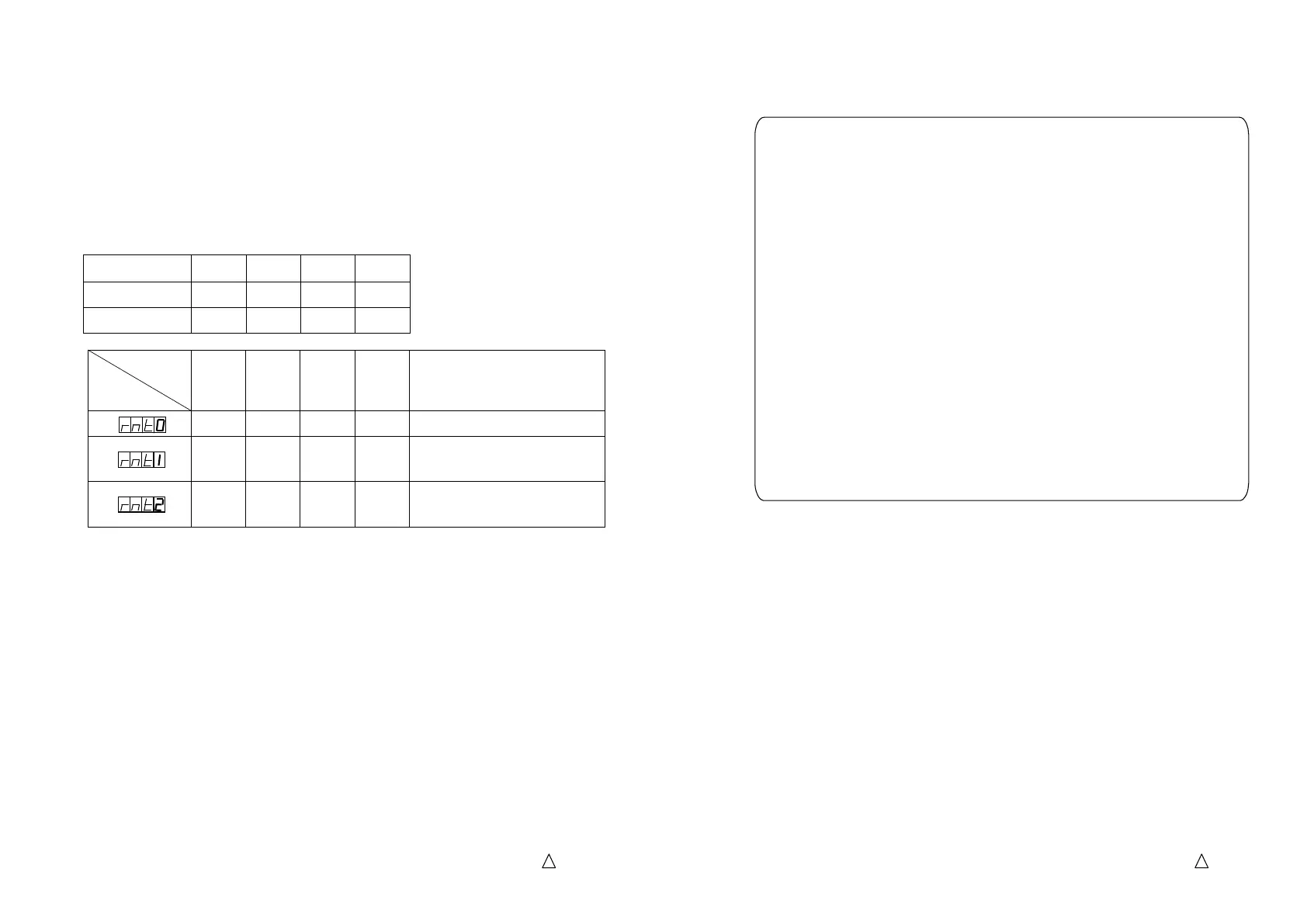

Combination No.

Function code

0 1 2 3 Remarks

Panel Panel Panel Panel Running by the stored data

4-20mA

Panel Panel Panel

The Combination No.0 determines

running by 4 – 20 mA current

control.

VR1 VR2 Panel Panel

The combination No.1 and 2

determine running by the exte

rheostats. See note below.

Speed Change Signal

Speed Change SignalSpeed Change Signal

Speed Change Signal

Combinations of “Open” or “Close” between terminals “COM” and“N1”, and “COM” and “N2”,

with contacts provided by customer, determines “Combination No.” See table below.

Combination of “Combination No.” and Function “Remote” determines behavior of C10-controller.

Combination No. 0 1 2 3

N1 and COM Open Close Open Close

N2 and COM Open Open Close Close

5

HTE302172

34/46

6

Note 1: After stored the stroke the partsfeeder runs by it even if the external signal “N1”

and “N2” are changed.

Data of stroke, drive frequency, soft start ramp-up time and on delay and off delay

times are stored for each Combination No.

Note 2:When the drive frequency is reset on Combination No.1 to 3, the partsfeeder must

be stopped and then change the external signals “N1” and “N2”.

How to store the Speed Change Signal

How to store the Speed Change SignalHow to store the Speed Change Signal

How to store the Speed Change Signal

Please follow the procedure below to set the Combination No.1 to No.3.

The procedure must start on the Combination No.0 or open the terminals “Com” and“N1”

and “Com” and “N2”.

1.

Set and save the stroke on the Combination No.0.

2.

Running the partsfeeder, input the external signal “N1” and “N2”

the Combination No.

After the action the Combination No. appears on the display as “SP-X” for “

or 2 or 3” for two seconds.

The drive frequency is that is set on the Combination No.0.

Caution:

Caution: Caution:

Caution: If the input signal “N1” and “N2”

are changed while the partsfeeder is

stopping the drive frequency stored is cleared and replaced with

the maximum.

3.

Dial the setting dial and select “Stroke” and set the stroke required with

the setting encoder.

4.

Push “Save”

button to store the data. After that the Combination No. stored appears

on the display for two seconds as “SP-X” for “X=1, 2, 3”.

Loading...

Loading...