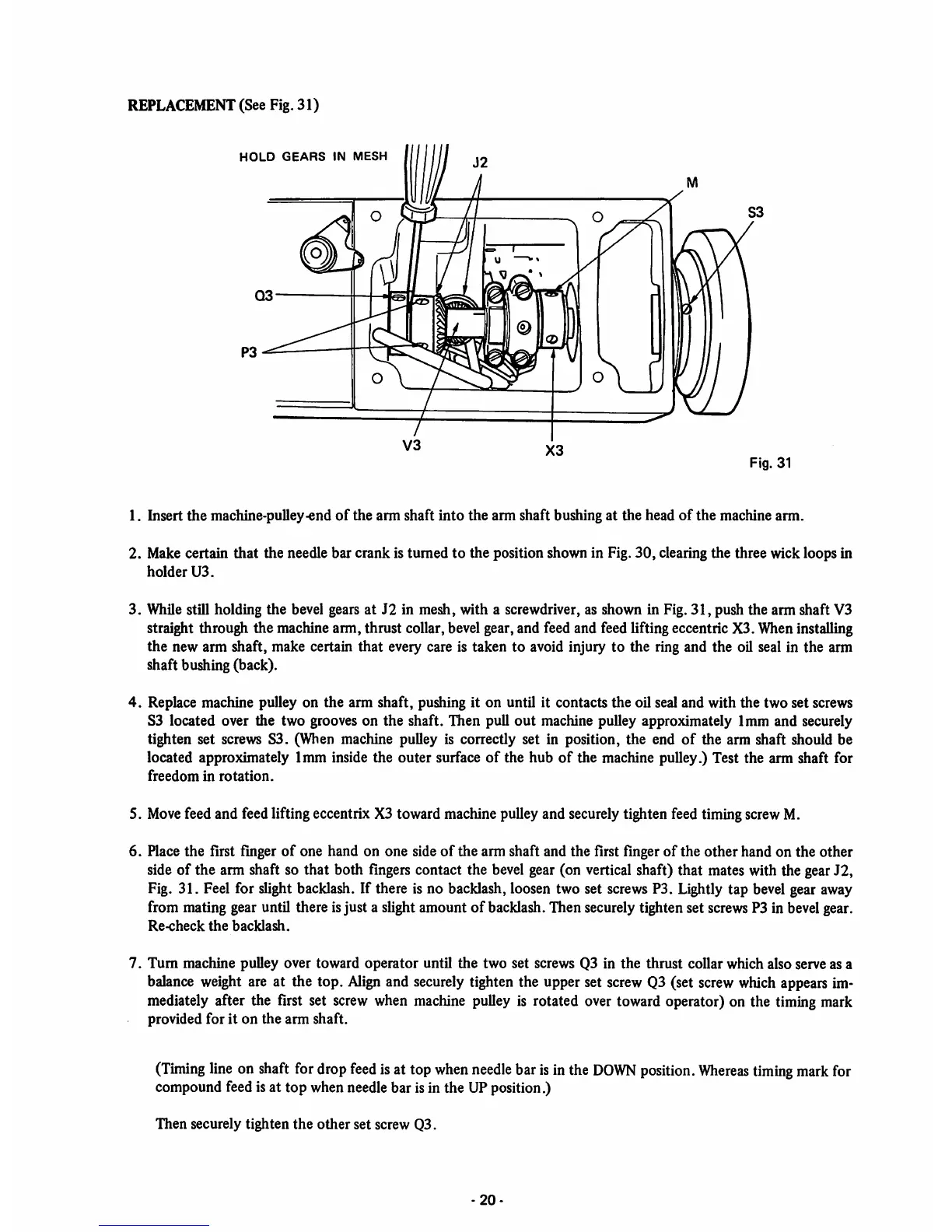

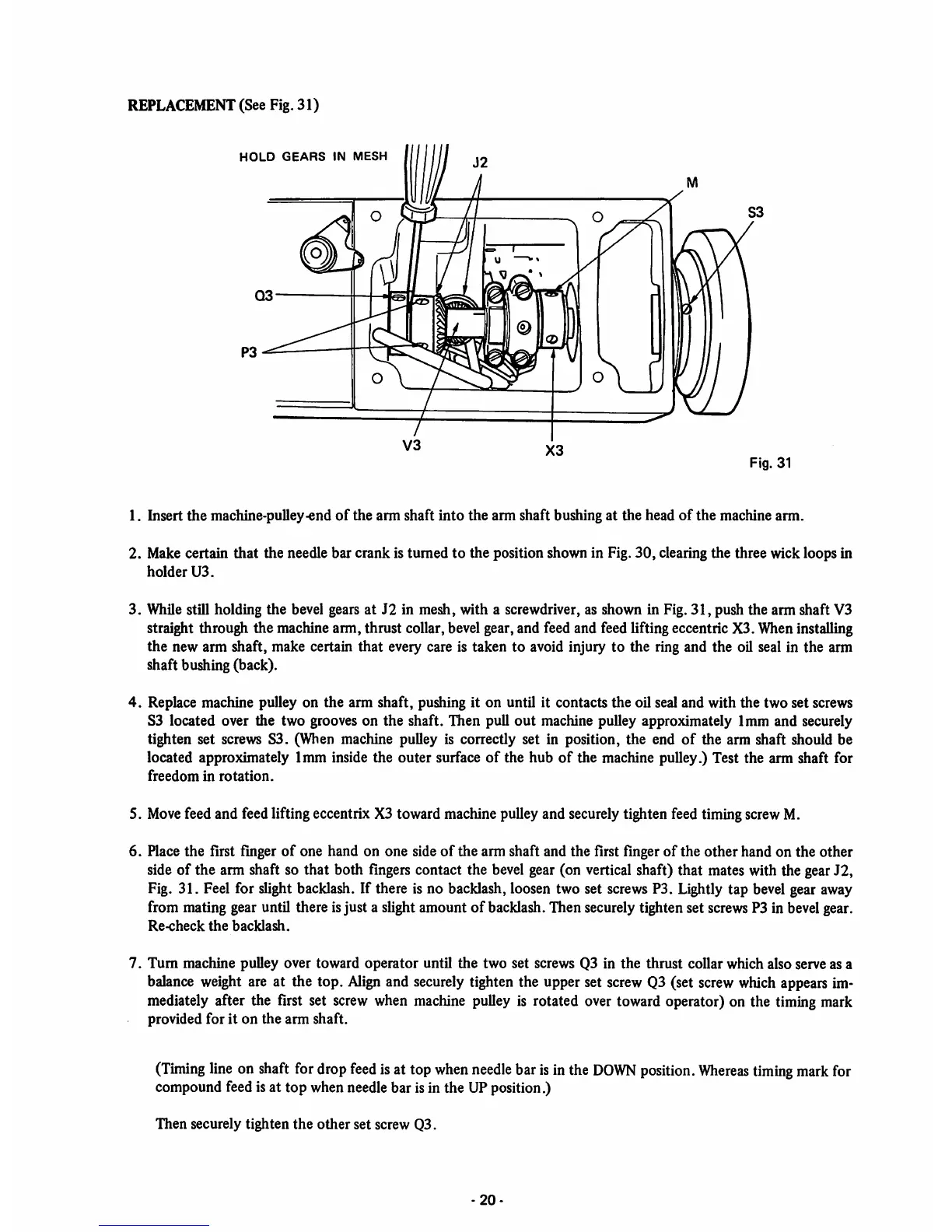

REPLACEMENT (See Fig. 31)

HOLD

GEARS

IN

MESH

[

Fig. 31

1. Insert

the

machine-pulley-end

of

the arm shaft

into

the arm shaft bushing at the head

of

the machine arm.

2. Make certain that the needle bar crank is turned to the position shown in Fig.

30,

clearing the three wick loops in

holder

U3.

3. While still holding the bevel gears at J2 in mesh, with a screwdriver, as shown in Fig.

31,

push the arm shaft V3

straight through the machine arm, thrust collar, bevel gear, and feed and feed lifting eccentric X3. Wheninstalling

the new arm shaft, make certain that every care is taken to avoid injury to the ring and the oil seal in the arm

shaft bushing (back).

4.

Replace machine pulley on the arm shaft, pushing it on until it contacts the oil seal and with the two set screws

S3 located over the two grooves on

the

shaft. Then pull

out

machine pulley approximately 1mm and securely

tighten set screws S3. (When machine pulley is correctly set in position, the end

of

the arm shaft should be

located approximately 1mm inside the outer surface

of

the hub

of

the machine pulley.) Test the arm shaft for

freedom

in

rotation.

5.

Move

feed and feed lifting eccentrix X3 toward machine pulleyand securelytighten feed timingscrewM.

6. Place the first finger

of

one hand on one side

of

the arm shaft and the first finger of the other hand on the other

side of the arm shaft so that both fingers contact the bevel gear (on vertical shaft) that mates with the gearJ2,

Fig. 31. Feel for slight backlash. If there is no backlash, loosen two set

screws

P3. Lightly tap bevel gear away

from mating gear until there isjust a slightamount of backlash.Then securelytighten set screwsP3 in bevelgear.

Re-check

the

backlash.

7.

Turn

machine pulley over toward

operator

until the two set screws Q3 in

the

thrust collar which also serve as a

balance weight are at the top.

Align

and securely tighten the upper set screw Q3 (set screw which appears im

mediately after the first set

screw

when

machine

pulley is rotated over toward operator) on the timingmark

provided for it

on

the

arm

shaft.

(Timing

line

on

shaft

for

drop

feed

isat top

when

needle

barisinthe

DOWN

position.

Whereas

timing

mark

for

compound feed is at top when needle bar is in the UP position.)

Then securely tighten

the

other

set screw Q3.

-20-

Loading...

Loading...